Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the hustle and bustle of daily life continues to accelerate, the quest for efficiency in meal preparation becomes more crucial than ever. Enter the sandwich making machine—a revolutionary innovation that has streamlined the process of creating delicious, homemade sandwiches. Today, let’s delve into the evolution of this kitchen gadget, exploring how it works, the benefits it offers, the various types available, and what the future holds for sandwich-making technology.

The art of sandwich making has come a long way since its inception. Originating in 1762, the sandwich was born out of a tale of convenience. John Montagu, the 4th Earl of Sandwich, was said to have requested a portable meal so he could continue his gaming without interruption. Thus, the sandwich was born, a simple yet revolutionary combination of bread, filling, and a little bit of history.

Over time, the sandwich evolved from a simple slice of bread with meat to a culinary canvas that could be adorned with an array of ingredients. The 19th century saw the rise of the sandwich as a staple in the United States, with the likes of the BLT and the club sandwich becoming household names. It wasn’t just the variety of fillings that expanded; the methods of preparation also began to diversify.

In the early days, sandwiches were made by hand, with bakers and home cooks alike shaping slices of bread and spreading fillings with a knife. The process was labor-intensive and time-consuming, but it was a testament to the ingenuity of those who sought to create a quick and satisfying meal. As the 20th century rolled in, the way we made sandwiches started to change.

The advent of the electric mixer brought about a new era in sandwich preparation. With the ability to mix and spread fillings more efficiently, sandwich shops and bakeries could produce sandwiches at a much faster pace. This innovation, however, was still limited to manual labor and the skill of the person spreading the fillings.

It wasn’t until the late 20th century that the first automated sandwich making machines began to emerge. These early machines were simple, often using a heated press to melt cheese and seal the edges of the sandwich. They were a step forward in efficiency but still required human intervention to load and unload the sandwiches.

As technology advanced, so did the capabilities of sandwich making machines. The introduction of programmable controls allowed for a variety of sandwich configurations, from simple ham and cheese to complex gourmet creations. The ability to adjust the temperature and pressure of the press meant that sandwiches could be made to perfection with each press.

The 21st century has seen a surge in innovation within the sandwich making machine industry. Modern machines are not only faster and more efficient but also more versatile. They can handle a wide range of bread types, from thin slices to thick ciabatta, and can accommodate a multitude of fillings, from cold cuts to hot ingredients.

The evolution of sandwich making has also been influenced by the rise of health consciousness. Many machines now offer options for low-fat spreads and healthier fillings, catering to a market that values both taste and nutrition. The ability to customize sandwiches to individual preferences has become a hallmark of modern sandwich making technology.

Today, the sandwich making machine is an integral part of the foodservice industry. From fast-food chains to gourmet cafes, these machines are used to produce a wide array of sandwiches at a rapid pace. They have not only increased efficiency but have also allowed for the creation of new sandwich concepts that were once unimaginable.

The evolution of sandwich making is a story of human ingenuity and the relentless pursuit of convenience. From the humble beginnings of the Earl of Sandwich’s gaming session to the sophisticated machines of today, the sandwich has become a symbol of culinary adaptability and the joy of a quick, satisfying meal. Whether it’s a simple ham and cheese or a gourmet creation with multiple layers and flavors, the sandwich making machine has played a significant role in shaping the way we enjoy this beloved food.

The dawn of the sandwich-making machine marked a significant shift in the culinary landscape, offering a blend of convenience and innovation. Initially, the art of sandwich making was a simple affair, often involving the hands-on assembly of bread, fillings, and condiments. However, as the 20th century progressed, the demand for efficiency in food preparation grew, leading to the creation of machines designed to streamline the process.

In the 1950s, the first automated sandwich makers began to emerge, offering a glimpse into the future of fast food. These early machines were often found in commercial settings, such as diners and fast-food restaurants, where speed and consistency were paramount. They were simple, mechanical devices that sandwiched bread slices together with a single press, creating uniform sandwiches at a rapid pace.

The introduction of the sandwich-making machine was met with skepticism by some, who believed that the very essence of a sandwich was in the personal touch. However, the machines quickly gained popularity due to their ability to handle high volumes of orders, reducing wait times and increasing productivity. For the first time, the idea of a sandwich as a mass-produced item took hold, reflecting the changing times and the rise of the fast-food industry.

As technology advanced, so did the capabilities of sandwich-making machines. The 1960s saw the development of more sophisticated models that could accommodate a wider variety of bread types and fillings. These machines were often equipped with adjustable settings, allowing operators to customize the sandwich thickness and the amount of pressure applied during the sealing process.

The 1970s brought about the birth of the modern sandwich-making machine, characterized by its programmable features and increased versatility. These machines could handle different bread sizes, crust options, and a multitude of fillings, from classic ham and cheese to exotic combinations that pushed the boundaries of taste. The introduction of heat-sealing technology further enhanced the machines’ ability to create a hermetically sealed sandwich, preserving freshness and flavor.

With the advent of the 1980s, sandwich-making machines began to incorporate electronic controls, making them more user-friendly and precise. The ability to program specific settings for different types of sandwiches meant that operators could cater to a diverse customer base with varying preferences. This era also saw the rise of the “sandwich shop” phenomenon, where the focus was on creating a variety of high-quality sandwiches using these innovative machines.

The 1990s and beyond witnessed a surge in the popularity of gourmet sandwiches, and the sandwich-making machine evolved to accommodate these more complex creations. Machines now featured additional features like heated plates for melting cheese, adjustable fillings dispensers, and even the ability to toast the bread to the desired crispness. The introduction of these advanced features allowed sandwich shops to offer a wide array of specialty sandwiches, from vegetarian to vegan, without compromising on speed or consistency.

Today, the sandwich-making machine is an integral part of the foodservice industry. It has become a symbol of efficiency and quality, capable of producing a wide range of sandwiches in a matter of seconds. The evolution of the sandwich-making machine has not only changed the way we think about sandwiches but has also influenced the way we approach food preparation in general.

The introduction of the sandwich-making machine was not just a technological advancement; it was a cultural shift. It represented the growing need for convenience in our fast-paced lives, and it paved the way for the rise of the modern fast-food culture. From the humble beginnings of a mechanical press to the sophisticated, programmable machines of today, the sandwich-making machine has come a long way, proving that even the simplest of foods can benefit from a touch of automation.

The Sandwich Making Machine: A Culinary Revolution

In the quest for efficiency and consistency in the art of sandwich preparation, the sandwich making machine emerged as a game-changer. These innovative devices have transformed the way we think about making sandwiches, offering a streamlined process that appeals to busy chefs, fast-food establishments, and even home cooks. Let’s delve into the intricate workings of these nifty gadgets.

The sandwich making machine typically consists of several key components that work together to create the perfect sandwich in mere seconds. At its core, the machine features a heated, flat surface designed to toast the bread while pressing it to achieve that coveted crunch and even browning.

Firstly, the bread is loaded into the machine, often through a slot or a conveyor belt system. Modern machines are designed to accommodate different bread sizes and shapes, from classic slices to larger, open-face sandwiches. The bread is then securely held in place, ensuring it doesn’t move during the pressing process.

Once the bread is in position, the machine’s heating elements activate. These elements can be electrically powered and may consist of heating strips or ceramic plates. They distribute heat evenly across the bread, which is crucial for achieving a uniform toast color and texture. The temperature of the heating elements can often be adjusted to suit various types of bread and desired levels of crispiness.

As the bread heats up, the pressure mechanism comes into play. Sandwich making machines are equipped with a system that applies consistent pressure to the bread. This pressure ensures that the filling is evenly distributed and compressed, preventing any sogginess or unevenness. The pressure can also be adjusted based on the sandwich’s ingredients and the desired outcome.

In some models, additional features enhance the sandwich-making experience. For example, steam might be introduced to soften the bread’s edges, making them more palatable. Cheese melting elements can also be integrated to quickly melt cheese toppings, adding a layer of gooey perfection to the sandwich.

Once the bread is toasted to the desired level and the pressure is applied, the sandwich is ready to receive its fillings. This is where the sandwich’s true character is formed. Ingredients such as lettuce, tomatoes, ham, turkey, cheese, and condiments are placed between the slices of bread. The machine’s design often allows for the placement of fillings on both sides of the bread, creating a sandwich that is both visually appealing and rich in flavor.

As the fillings are added, the sandwich is usually passed through the machine a second time to ensure everything is sealed and pressed properly. This second pass is particularly important for sandwiches with wet or juicy ingredients, as it helps to maintain structural integrity and prevent sogginess.

The sandwich making machine often includes a cooling stage after the pressing process. This is a crucial step, as it allows the sandwich to cool slightly before being removed, which can prevent sticking and make it easier to handle.

Finally, the sandwich is ejected from the machine, often through an exit slot or onto a conveyor belt. The result is a perfectly pressed, toasted, and filled sandwich, ready to be served hot or at room temperature.

In more sophisticated models, the sandwich making machine may also offer programmable settings. Users can set the desired level of browning, the amount of pressure, the time for toasting, and even the temperature of the fillings. This customization allows for a wide range of sandwich possibilities, from the simple ham and cheese to the elaborate gourmet creation.

In summary, the sandwich making machine operates through a series of precise steps, from heating and pressing to filling and cooling, all designed to ensure that the final product is not only visually appealing but also consistent in taste and texture. With its ability to cater to various bread types, fillings, and personal preferences, the sandwich making machine has become an indispensable tool in the kitchen, revolutionizing the way we enjoy our sandwiches.

Incorporating a sandwich making machine into your kitchen can revolutionize the way you prepare these beloved meals. Here’s a closer look at the myriad benefits that come with this convenient appliance:

Efficiency in MinutesTime is a precious commodity, and a sandwich making machine can turn out perfectly toasted sandwiches in mere minutes. Say goodbye to the days of manually grilling or toasting your bread, as these machines streamline the process, allowing you to focus on other tasks or simply enjoy a quick, homemade meal.

Consistent Results Every TimeOne of the most significant advantages of using a sandwich making machine is the consistency it brings to sandwich preparation. Whether you’re making a simple ham and cheese or a gourmet creation with multiple fillings, the machine ensures even toasting and precise heating, resulting in a sandwich that’s consistently delicious.

Versatility in DesignModern sandwich making machines come in various designs, each tailored to different needs and preferences. From compact, countertop models to larger, commercial-grade appliances, there’s a machine out there for every kitchen. Some feature adjustable heat settings, non-stick surfaces, and even removable parts for easy cleaning, making them versatile tools for both home and professional use.

Healthier Cooking OptionsWith a sandwich making machine, you can enjoy sandwiches that are healthier than those from fast-food joints or pre-packaged options. By controlling the ingredients and cooking process, you can reduce the amount of oil, salt, and preservatives used. Plus, the ability to cook with less fat and at lower temperatures can help retain more of the nutrients in your ingredients.

Customization to Suit Your TastePersonalize your sandwiches to your heart’s content. From selecting the type of bread to choosing your favorite fillings, a sandwich making machine allows you to craft the perfect sandwich every time. Whether you’re a fan of classic combinations or enjoy experimenting with new flavors, these machines can accommodate your culinary whims.

Easier CleanupCleaning up after cooking can be a hassle, but sandwich making machines often make the process much simpler. Many models have non-stick surfaces that prevent food from sticking, and some even come with removable parts that can be washed in the dishwasher. This means less time spent scrubbing and more time enjoying your sandwich.

Cost-Effective and Environmentally FriendlyUsing a sandwich making machine can be a cost-effective and environmentally friendly choice. By making your sandwiches at home, you can avoid the expense of dining out or buying pre-made sandwiches. Additionally, reducing the need for disposable packaging and minimizing food waste can contribute to a greener lifestyle.

Enhanced PresentationA sandwich made with a sandwich making machine often looks as good as it tastes. The evenness of the toasting and the crisp edges can make your homemade creation look as appealing as those found in high-end restaurants. This can be especially beneficial if you’re entertaining guests or looking to impress someone special.

Perfect for Busy LifestylesFor those with busy schedules, a sandwich making machine is a lifesaver. Whether you’re rushing to work, have a family to feed, or simply want a quick meal after a long day, these machines can provide a fast and satisfying solution. They’re perfect for breakfast, lunch, or even a late-night snack.

In conclusion, the benefits of using a sandwich making machine are clear. From efficiency and consistency to health and customization, these appliances offer a multitude of advantages that can enhance your sandwich-making experience. Whether you’re a sandwich aficionado or just looking for a convenient way to prepare a quick meal, a sandwich making machine is a valuable addition to any kitchen.

In the realm of culinary innovations, sandwich making machines have emerged as versatile tools that cater to both home cooks and busy professionals. Here’s a glimpse into the diverse types of sandwich making machines available today, each designed with unique features and functionalities to meet various needs:

Manual Press ModelsThese machines often resemble a large, flat press and are designed for easy, hands-on use. They typically consist of two flat plates that you place your sandwich filling between. The user manually presses the plates together, using a lever or handle, to achieve a uniform, compacted sandwich. Manual press models are perfect for those who prefer a traditional approach or have a limited kitchen setup.

Automatic Pressure CookersCombining the functionality of a pressure cooker with a sandwich maker, these appliances are a hit for those looking for convenience and efficiency. They automatically seal the sandwich in airtight containers, applying pressure to cook the filling and seal the bread. This method ensures that the sandwich stays warm and moist, making it an ideal choice for picnics or on-the-go meals.

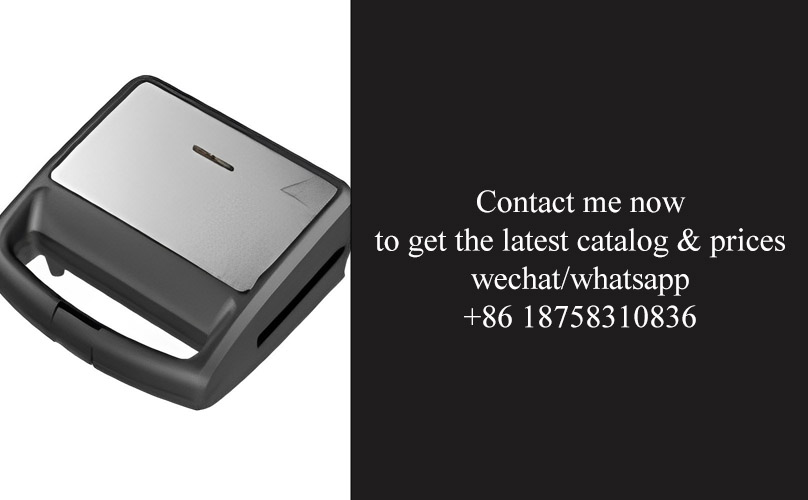

Electric Sandwich PressesElectric sandwich presses are the modern take on the classic stovetop press. They come with adjustable heat settings and sometimes include features like a non-stick surface and a drip tray to catch any excess moisture. These models offer precision and consistency, allowing users to achieve a perfect golden-brown crust every time.

Commercial Grade Sandwich MakersFor those who run a café, restaurant, or catering business, commercial-grade sandwich makers are a must. These machines are built to handle high volumes and often come with advanced features like adjustable heating elements, programmable settings, and durable construction. They can produce sandwiches at a rapid pace, ensuring customer satisfaction without the wait.

Toaster Sandwich MakersPerfect for quick and simple breakfasts, toaster sandwich makers have a sleek, compact design. They are often used to create classic ham and cheese or egg and bacon sandwiches. These appliances usually have adjustable temperature settings and are suitable for making both open-faced and closed sandwiches.

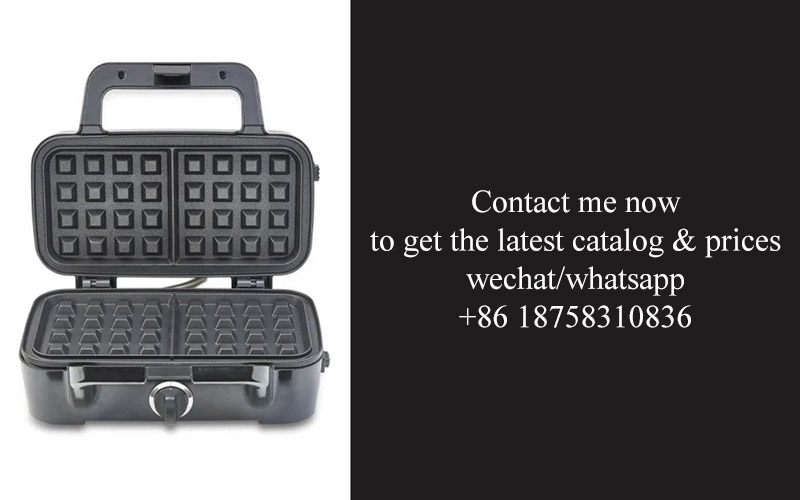

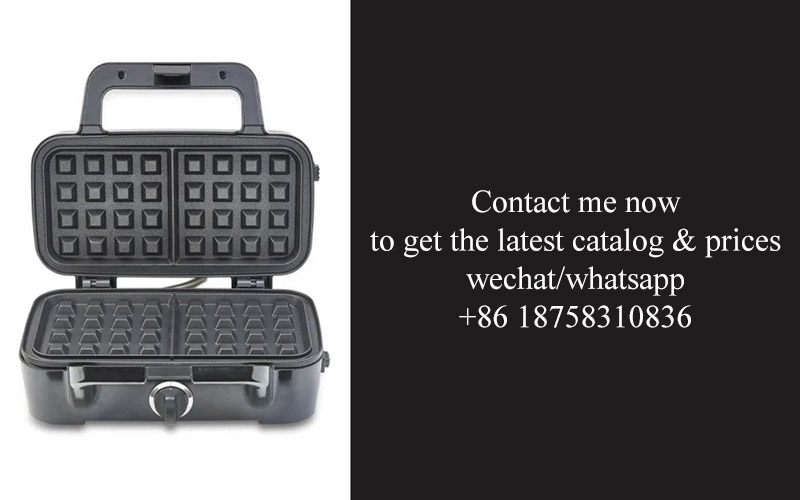

Combination Sandwich and Waffle MakersFor those who love to mix and match, combination sandwich and waffle makers are a game-changer. These versatile appliances allow you to make not only sandwiches but also waffles at the same time. The dual-purpose feature saves time and space, making them ideal for families or anyone who enjoys a variety of breakfast options.

Roller Sandwich MakersRoller sandwich makers offer a unique way to craft your sandwiches. They use a series of heated plates to flatten and roll the bread, ensuring even distribution of fillings. This method is perfect for creating thin, roll-style sandwiches that are both visually appealing and easy to eat.

Electric Griddles with Sandwich AttachmentsElectric griddles can be transformed into sandwich-making stations with the addition of specialized attachments. These attachments are designed to fit onto the griddle and can be used to press and cook sandwiches just like a traditional press. This type of machine is ideal for those who already have a griddle in their kitchen and want to expand its functionality.

Steam Sandwich MakersSteam sandwich makers are a healthier alternative to their high-heat counterparts. These machines use steam to cook the sandwich, preserving more of the nutrients and reducing the need for excessive oil. They are perfect for individuals who are conscious about their dietary intake and still want a deliciously toasted sandwich.

Each of these sandwich making machines comes with its own set of benefits and considerations. Whether you’re looking for a simple, no-fuss solution or a high-tech, commercial-grade appliance, the variety available ensures that there’s a sandwich maker out there to suit your needs and preferences.

In the quest for the perfect sandwich, the right tools can make all the difference. Here’s how to master the art of sandwich making with a sandwich making machine, with some essential tips to ensure your creations are nothing short of delightful.

Consistent Bread SlicingAchieving uniform slices of bread is a challenge without a machine. A sandwich maker ensures that each piece is cut to the same thickness, which is crucial for even toasting and filling distribution.

Perfectly Toasted BreadThe key to a great sandwich is a crispy, golden-brown exterior. Most sandwich makers come with adjustable heat settings, allowing you to control the level of toast to your liking. Experiment with different settings to find the perfect balance between a crunchy crust and a soft interior.

Evenly Distributed FillingsThe sandwich press design is engineered to keep fillings in place while cooking. This means you can pile on the toppings without worrying about them sliding off. Use this to your advantage by layering a variety of ingredients for a rich and satisfying sandwich.

Customizable Pressing OptionsSome machines offer adjustable pressing options, allowing you to control the pressure applied to the sandwich. This can be particularly useful if you prefer a more compact sandwich or if you’re using softer bread that might otherwise fall apart.

Versatility in IngredientsDon’t limit yourself to the traditional ham and cheese. A sandwich maker can handle a wide array of ingredients, from savory to sweet. Think about adding avocado, smoked salmon, or even a dollop of hummus for a unique twist.

Efficiency in Preparing LunchIf you’re short on time, a sandwich maker can be a lifesaver. It prepares your sandwich in minutes, making it an ideal choice for busy mornings or when you need a quick lunch option.

Clean-Up is a BreezeMany sandwich makers are designed with non-stick surfaces, which means cleaning up is a breeze. Simply wipe away any spills or crumbs, and you’re ready to go.

Portability and ConvenienceFor those who are always on the go, some sandwich makers are compact and portable. You can take them to work, school, or on road trips, ensuring you always have a homemade sandwich at your fingertips.

Experiment with FlavorsUse the sandwich maker to experiment with different flavors and combinations. Try adding a sprinkle of herbs, a drizzle of honey mustard, or a dash of hot sauce for a pop of flavor.

Keep It FreshIf you’re making a sandwich for later, consider adding a slice of cheese or a dollop of mayonnaise just before pressing. This ensures that the cheese melts and the fillings stay fresh until you’re ready to eat.

Maintain the MachineRegularly check the sandwich maker for any signs of wear and tear. Clean it after each use to prevent food buildup and ensure it continues to function smoothly.

Safety FirstAlways follow the manufacturer’s instructions when using the sandwich maker. Be cautious when handling the hot surfaces, and never leave the machine unattended while in use.

Innovative FeaturesSome models come with innovative features like adjustable temperature controls, removable plates for easy cleaning, or even a built-in timer. Look for these features if you want a sandwich maker that offers extra convenience and functionality.

Share the LoveIf you’re hosting a gathering or a picnic, a sandwich maker can be a hit with guests. It’s a fun way to involve everyone in making their own sandwiches, fostering a sense of community and enjoyment.

Creative FillingsGet creative with your fillings. Consider using leftover meats, cheeses, or vegetables from your fridge. The sandwich maker is a great way to use up ingredients that might otherwise go to waste.

By following these tips, you’ll be well on your way to making perfect sandwiches with your sandwich making machine, ensuring that every bite is a delightful experience.

In the ever-evolving world of culinary innovations, sandwich making technology is on the rise, promising a future that’s both efficient and exciting. From the rise of smart appliances to the integration of artificial intelligence, here’s a glimpse into the future of sandwich making technology.

Smart Appliances and ConnectivityImagine a world where your sandwich maker not only prepares your meals but also communicates with your smartphone. Smart sandwich making machines are on the horizon, offering connectivity features that allow you to monitor and control the cooking process remotely. These appliances could learn your preferences over time, adjusting the temperature and cooking time to perfection.

Advanced Materials and Cooking TechniquesThe future of sandwich making may see the use of advanced materials that not only enhance the taste and texture of sandwiches but also improve their nutritional value. For instance, high-tech breads could be developed with anti-stale properties, ensuring your sandwich stays fresh longer. Cooking techniques might also evolve, with machines capable of precisely controlling the heat distribution to achieve the perfect toasted crust without burning the inside.

Personalization at ScaleWhile the idea of a sandwich making machine might evoke images of mass-produced fare, the future holds the promise of personalized sandwiches at scale. Through the use of 3D printing technology, it’s conceivable that machines could create custom sandwiches with specific ingredients and textures, tailored to individual dietary preferences and nutritional needs.

Automation in the KitchenAutomation is not just about machines; it’s about the integration of technology into our daily routines. In the future, kitchen appliances might be part of a larger system that automates meal preparation. A sandwich making machine could be just one component of a kitchen ecosystem that includes automated ingredient dispensers, waste recyclers, and even meal planning software.

Integration with AI and Machine LearningArtificial intelligence (AI) and machine learning (ML) are poised to revolutionize the way we interact with our kitchen appliances. A sandwich making machine equipped with AI could analyze your eating habits, suggest new sandwich combinations, and even order ingredients online when you’re running low. The machine could learn from your feedback, adjusting recipes and cooking times to better suit your taste.

Sustainable and Eco-Friendly SolutionsAs sustainability becomes a more pressing concern, the future of sandwich making technology will likely focus on eco-friendly solutions. Machines could be designed to use less energy, with solar-powered options becoming more common. Additionally, the materials used in sandwich making could be biodegradable or recyclable, reducing the environmental impact of our favorite meals.

Enhanced Health and Wellness FeaturesWith a growing emphasis on health and wellness, sandwich making machines could incorporate features that promote better eating habits. They might be capable of preparing sandwiches with whole grains, lean proteins, and fresh vegetables, all while minimizing the addition of unhealthy fats and sugars. These machines could even alert you to the nutritional content of your sandwich, helping you make informed choices.

The Rise of Hybrid Sandwich MakersThe future might see the development of hybrid sandwich makers that combine the functionality of a traditional sandwich press with the versatility of a toaster oven. These machines could offer a variety of cooking options, from grilling to toasting, allowing for a wider range of sandwich styles and ingredients.

Interactive and Educational FeaturesSandwich making machines could also incorporate interactive and educational features, especially in a commercial setting. They might provide nutritional information, cooking tips, and even historical trivia about sandwiches, turning the sandwich-making process into an engaging experience.

Global Trends and Cultural FusionAs technology becomes more accessible, the future of sandwich making could see a blend of global culinary trends. Machines might be able to replicate the flavors and textures of sandwiches from around the world, offering a taste of international cuisine at home.

In conclusion, the future of sandwich making technology is a blend of innovation, sustainability, and personalization. It’s a future where the humble sandwich could become a culinary marvel, made with precision and tailored to the individual, all while being mindful of the environment and health.

In embracing efficiency in sandwich preparation, the conclusion lies in the seamless fusion of technology and culinary art. The journey from handcrafted sandwiches to the precision of sandwich-making machines has transformed the way we savor these beloved snacks. As we reflect on the evolution, it’s clear that the future of sandwich making technology is not just about convenience; it’s about innovation, sustainability, and the endless possibilities that lie ahead.

The rise of sandwich-making machines has brought about a new era of consistency and speed in the preparation of these portable meals. These devices, once a rarity in domestic kitchens, have now become a staple in both commercial and home settings. The ability to craft uniform, perfectly toasted sandwiches in mere minutes has revolutionized the way we approach lunchtime.

As we delve into the intricacies of these machines, we find that their designs vary widely, catering to different preferences and needs. From the classic countertop models to the compact, portable units, each type offers its own set of features and benefits. The variety ensures that whether you’re a busy professional, a sandwich shop owner, or a home chef, there’s a machine out there tailored to your specific requirements.

One of the most notable aspects of modern sandwich-making technology is the emphasis on health and wellness. With the increasing awareness of dietary choices, machines are now equipped with features that allow for the creation of sandwiches that are not only delicious but also nutritious. The ability to control the cooking temperature and the inclusion of health-conscious ingredients have made these machines a favorite among health-conscious consumers.

The convenience of sandwich-making machines is undeniable. They save time, reduce the stress of preparing a meal, and can even be used to experiment with new flavors and combinations. Imagine being able to have a gourmet-quality sandwich ready in a matter of minutes, without the hassle of toasting bread and flipping it over. The ease of use is a game-changer for those who appreciate a quick and effortless meal.

Moreover, the future of sandwich-making technology is poised to become even more integrated into our daily lives. With advancements in smart kitchen appliances, these machines may soon be connected to our smartphones, allowing for remote control and customization of our sandwiches. Imagine being able to program your sandwich preferences and have it ready for you when you walk through the door.

In terms of sustainability, sandwich-making machines are also making strides. As environmental concerns grow, manufacturers are focusing on creating machines that are energy-efficient and made from recyclable materials. This not only benefits the planet but also appeals to consumers who are increasingly conscious of their ecological footprint.

As we look ahead, the future of sandwich-making technology is not just about improving the machines themselves. It’s about creating a culture that values efficiency without compromising on quality. The next generation of sandwich-making machines might incorporate features like automated bread selection, based on the user’s dietary restrictions or preferences, or even the ability to incorporate fresh ingredients like herbs and vegetables directly into the sandwich.

In conclusion, the sandwich-making machine has become an indispensable tool in the kitchen, bridging the gap between tradition and modern convenience. It’s a testament to how technology can enhance our daily lives, making the simple act of making a sandwich a delightful and efficient experience. As we continue to innovate and improve upon these machines, the future of sandwich-making technology promises to be both exciting and sustainable, ensuring that the joy of a perfectly prepared sandwich is within reach for everyone.