Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where quick and satisfying meals are in high demand, the sandwich has emerged as a versatile and beloved staple. It’s not just a simple meal, but a culinary canvas that can be transformed into a myriad of flavors and textures. Central to this dynamic food scene are the sandwich machines, the unsung heroes of commercial kitchens. They’ve revolutionized the way we make and enjoy sandwiches, and today, we delve into the intricacies of choosing the right sandwich machine manufacturer to meet your specific needs.

In recent years, the sandwich has transcended its humble origins to become a global phenomenon. Once a simple meal, it has now evolved into a culinary staple that caters to diverse tastes and preferences. The rise of sandwich culture can be attributed to several factors that have transformed this once straightforward dish into a multi-faceted food trend.

The convenience factor is a major driver behind the sandwich’s popularity. With busy lifestyles and the increasing demand for on-the-go meals, sandwiches offer a quick and satisfying solution. Whether it’s a busy professional in the city or a student rushing to class, the sandwich’s portability makes it an ideal choice for those with limited time for meals.

Cultural exchanges have also played a significant role in the evolution of sandwich culture. As people travel more frequently, they bring back flavors and ingredients from around the world, which are then incorporated into local sandwich recipes. This fusion of cultures has led to a plethora of unique and innovative sandwich variations, each with its own distinct character.

The rise of health-conscious eating habits has further fueled the sandwich’s popularity. With an increasing number of individuals seeking balanced and nutritious meals, sandwiches offer a versatile platform for incorporating a variety of ingredients, from lean proteins to fresh vegetables and whole grains. This has made sandwiches a go-to option for those looking to maintain a healthy diet without sacrificing taste.

The rise of social media has also had a profound impact on sandwich culture. Influencers and food bloggers have taken to platforms like Instagram and TikTok to showcase their culinary creations, often featuring sandwiches. This exposure has not only inspired home cooks but has also influenced restaurant menus, leading to a surge in creative and visually appealing sandwich offerings.

Moreover, the convenience store industry has embraced the sandwich as a key product. These establishments have recognized the demand for quick and easy meals, and sandwiches have become a staple in their offerings. With the proliferation of convenience stores worldwide, the sandwich has become a part of everyday life for millions of people.

The food truck revolution has also contributed to the sandwich’s rise. These mobile food vendors have brought the sandwich to the streets, offering a variety of flavors and styles that appeal to a wide audience. The communal aspect of food trucks, where people gather to enjoy their meals, has also helped to foster a sense of community around the sandwich.

The growth of the fast-casual dining sector has been another significant factor. Chains like Panera Bread and Chipotle have capitalized on the sandwich’s versatility, offering customizable options that allow customers to build their own meals. This has given the sandwich a new level of personalization, making it even more appealing to consumers.

In the realm of gourmet dining, the sandwich has also found a place. Chefs have taken the traditional sandwich and elevated it to an art form, using high-quality ingredients and innovative techniques to create gourmet sandwiches that are as much a culinary experience as they are a meal.

The rise of sandwich culture is a testament to the adaptability and appeal of this dish. From the streets of New York to the bustling markets of Tokyo, the sandwich has become a universal symbol of comfort and convenience. As the world continues to evolve, it’s likely that the sandwich will continue to evolve alongside it, bringing new flavors and experiences to the table.

In the bustling heart of commercial kitchens, sandwich machines have become an indispensable tool for efficiency and consistency. These marvels of modern cuisine streamline the process of preparing sandwiches, allowing chefs and kitchen staff to cater to the fast-paced demands of a busy establishment. Let’s delve into the pivotal role these machines play in commercial kitchens.

The automation of sandwich preparation not only saves time but also ensures that each sandwich is crafted with uniformity, reducing the likelihood of human error. From the slicing of bread to the precise placement of fillings, sandwich machines are designed to perform these tasks with precision, allowing for a seamless workflow.

Consider the breakfast rush at a café. Orders for a variety of sandwiches pour in, each with specific requirements. A sandwich machine can quickly toast the bread, apply butter or mayonnaise, and fill it with the requested ingredients, all in a matter of seconds. This efficiency means that the kitchen can handle a higher volume of orders without sacrificing quality.

In high-volume restaurants, the speed at which sandwiches are prepared is crucial. The ability to stack orders one after another on a conveyor belt, with each sandwich machine handling a specific stage of the process, is a game-changer. It allows chefs to focus on more complex dishes, while ensuring that the sandwiches are ready in a timely manner.

Moreover, these machines are versatile. They can handle a wide range of bread types, from thick baguettes to thin tortillas, making them suitable for various sandwich styles and dietary preferences. Whether it’s a classic ham and cheese or a gourmet avocado and smoked salmon creation, a sandwich machine can accommodate the diverse tastes of patrons.

Hygiene is another critical aspect in commercial kitchens, and sandwich machines play a significant role in maintaining it. These machines are designed to be easily cleaned and sanitized, reducing the risk of cross-contamination. The automated process also minimizes the need for hand contact with food, further enhancing safety standards.

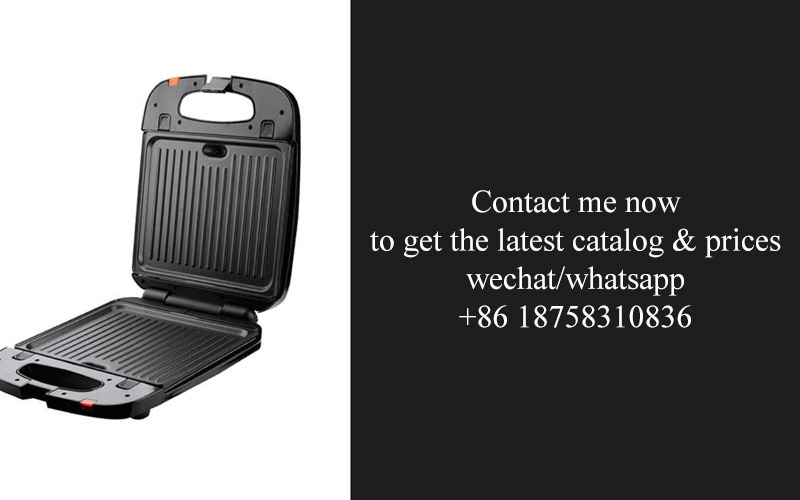

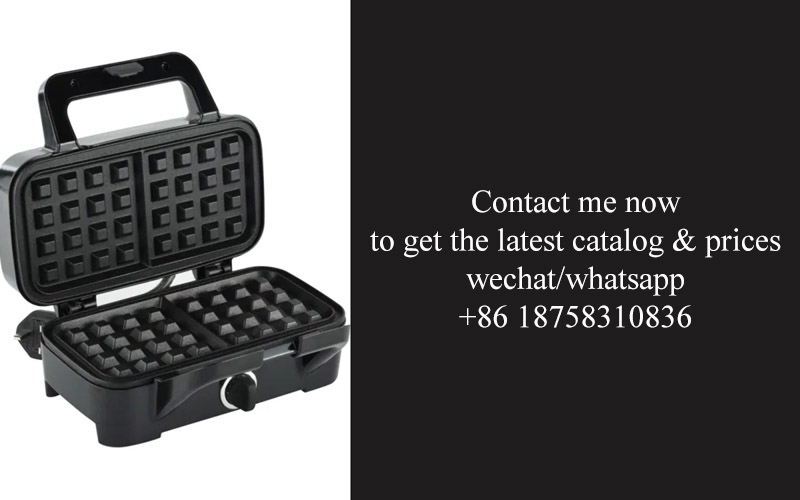

The use of sandwich machines isn’t limited to traditional sandwiches. They are also employed in the preparation of wraps, paninis, and even gourmet sliders. The ability to press and toast the bread to perfection creates a golden crust that is irresistible to customers, adding to the appeal of the final product.

Additionally, the consistency in the texture and temperature of the sandwiches is something that manual preparation can’t always achieve. A sandwich machine ensures that each component, from the melted cheese to the crisp lettuce, is at the ideal temperature and texture, enhancing the overall dining experience.

In the world of fast food and quick-service restaurants, speed is king. Sandwich machines enable these establishments to offer grab-and-go options that are not only fast but also delicious. This convenience is a major draw for customers looking for a quick bite on the go.

Moreover, the energy efficiency of these machines is a significant advantage. They are designed to operate with minimal energy consumption, which is not only cost-effective but also environmentally friendly. As sustainability becomes a growing concern, commercial kitchens are increasingly looking for solutions that balance efficiency with ecological responsibility.

The integration of sandwich machines into commercial kitchens has also led to the development of innovative sandwich variations. Chefs are now experimenting with different flavors, ingredients, and cooking techniques, pushing the boundaries of what a sandwich can be. This creativity has expanded the market and opened up new opportunities for businesses to differentiate themselves.

In summary, sandwich machines are the backbone of many commercial kitchens. They provide speed, consistency, and efficiency, all while contributing to a cleaner, safer, and more innovative culinary environment. From the early morning rush to the late-night snack, these machines ensure that the sandwich is always ready to delight the taste buds of hungry patrons.

In the bustling world of commercial kitchens, the choice of equipment can make or break a business. When it comes to sandwich-making, a reliable sandwich machine manufacturer is the backbone of a successful operation. Here are some compelling reasons why opting for a reputable manufacturer is crucial:

The Consistency of QualityA reliable sandwich machine manufacturer ensures that every sandwich served is consistent in quality. From the uniformity of the bread slices to the precise distribution of fillings, these machines are designed to deliver the same level of excellence with each use. This consistency is not just about taste; it’s about customer satisfaction and brand reputation.

Durability and LongevityCommercial kitchens are tough environments, and the equipment they rely on must withstand the rigors of daily use. A reputable manufacturer understands this and builds machines that are not only robust but also designed to last. Investing in a durable sandwich machine means fewer breakdowns, less downtime, and a lower total cost of ownership over time.

Customization for Specific NeedsEvery business has its unique requirements, and a reliable sandwich machine manufacturer offers customization options. Whether it’s adjusting the size of the sandwiches, accommodating different bread types, or integrating additional features like toasting or cheese melting, these manufacturers can tailor the machines to fit the specific needs of your kitchen.

Efficiency and SpeedIn a commercial setting, time is money. A high-quality sandwich machine can significantly increase the speed of service, allowing your kitchen staff to prepare more sandwiches in less time. This efficiency is especially important during peak hours when long lines can lead to frustrated customers and lost sales.

Ease of MaintenanceNo matter how advanced a sandwich machine is, it will eventually require maintenance. A reliable manufacturer understands this and designs their machines with ease of maintenance in mind. From accessible parts to clear instructions, these machines are built to be service-friendly, reducing the time and effort needed to keep them running smoothly.

Safety FeaturesFood safety is paramount in commercial kitchens, and a reputable sandwich machine manufacturer includes safety features in their designs. From non-slip surfaces to easy-to-clean components, these machines are engineered to minimize the risk of accidents and cross-contamination, ensuring a safe working environment.

Innovation and UpgradesThe food industry is always evolving, and a reliable manufacturer stays ahead of the curve by offering innovative solutions. Whether it’s integrating new technologies, energy-efficient designs, or eco-friendly materials, these manufacturers are committed to providing upgrades that can help your business stay competitive and sustainable.

Customer Support and ServiceA reliable sandwich machine manufacturer stands behind their products with exceptional customer support. From pre-sales consultations to after-sales service, they are there to help with any issues that may arise. This level of support can be the difference between a smoothly running kitchen and one that’s constantly battling equipment problems.

Brand Reputation and TrustUltimately, the reputation of a sandwich machine manufacturer speaks volumes. A well-established brand with a history of satisfied customers is a testament to the quality and reliability of their products. Choosing a manufacturer with a strong reputation can give you peace of mind, knowing that you’re investing in a product that has been proven to perform.

In conclusion, the role of a reliable sandwich machine manufacturer in a commercial kitchen cannot be overstated. From the quality and durability of the machines to the customization options and customer support, these manufacturers are instrumental in ensuring that your sandwich-making operation runs smoothly, efficiently, and profitably.

In the bustling world of commercial kitchens, the right sandwich machine can be the cornerstone of efficient service and high-quality output. Here are several key features to consider when selecting a commercial sandwich machine:

Versatility: A sandwich machine that can cater to a variety of sandwich types is invaluable. Look for models that can handle different bread sizes, from thin baguettes to thick submarine loaves, and accommodate a range of fillings from classic ham and cheese to gourmet options like avocado and smoked salmon. The ability to customize the thickness of the sandwich and the temperature of the cooking plate ensures that you can meet the diverse tastes of your customers.

Even Cooking: Consistent cooking is essential for a great-tasting sandwich. High-quality sandwich machines often feature even heating elements that prevent cold spots and overcooking. This feature ensures that every sandwich comes out perfectly toasted and heated throughout, without burning or drying out the bread.

Speed and Capacity: In a commercial setting, time is of the essence. A sandwich machine that can produce sandwiches quickly and handle a high volume of orders without compromising on quality is a must. Look for machines that offer fast heating and cooling cycles, and have a capacity that matches your peak hours of operation.

Ease of Use and Maintenance: A user-friendly design can greatly reduce the stress of kitchen staff. A commercial sandwich machine should be easy to load, operate, and clean. Features like adjustable controls, non-stick cooking plates, and easy-to-access components make maintenance a breeze. This not only saves time but also ensures that the machine remains in top working condition for longer.

Safety Features: Safety should never be compromised, especially in a kitchen environment. Ensure that the sandwich machine you choose has built-in safety features such as automatic shut-off in case of overheating, non-slip surfaces to prevent accidents, and durable materials that can withstand the rigors of a commercial kitchen.

Energy Efficiency: Running costs are a significant factor in the operation of any commercial kitchen. An energy-efficient sandwich machine can save you money on electricity bills over time. Look for models that have been designed with energy conservation in mind, such as those with smart heating controls and efficient insulation.

Customization and Branding: In today’s competitive market, the ability to customize your sandwich machine can help you stand out. Some machines offer branding options, such as a custom imprint on the cooking plate, which can promote your business and add a personal touch to each sandwich.

Durability: The life expectancy of a commercial sandwich machine can be significantly impacted by its construction. Look for machines made from high-quality materials that are designed to withstand the demands of a busy kitchen. A sturdy build ensures that your investment will pay off in the long run.

Warranty and Customer Support: A reliable manufacturer will offer a solid warranty and excellent customer support. This is crucial in case you encounter any issues with your sandwich machine. A good warranty can provide peace of mind, knowing that you’re covered if something goes wrong.

Innovation: Finally, consider the innovation behind the sandwich machine. Look for features that may not seem essential at first glance but can make a significant difference in the overall performance and user experience. This could include features like programmable settings for different sandwich types, easy-to-change parts, or advanced heating technologies.

Choosing the right commercial sandwich machine requires careful consideration of these features. The right machine can streamline your kitchen operations, enhance customer satisfaction, and ultimately contribute to the success of your business.

In the bustling world of fast-food and casual dining, the right sandwich equipment can be the secret ingredient to a business’s success. Let’s delve into some success stories that showcase how the right sandwich equipment has propelled various establishments to the top.

Consider the quaint little sandwich shop on the corner. Once just a quaint establishment known for its homemade flavors, it transformed into a local favorite thanks to a high-quality commercial sandwich press. The once labor-intensive process of crafting sandwiches was streamlined with the introduction of a machine that could press and toast bread with precision. The consistency in the sandwiches’ appearance and texture brought a sense of professionalism to the shop, making it a go-to spot for busy professionals looking for a quick yet satisfying meal.

Then there’s the trendy café that made a name for itself by serving gourmet sandwiches. Their secret weapon? A commercial sandwich maker that could handle a variety of bread types and fillings, from delicate ciabatta to hearty focaccia. The machine’s ability to cook and toast sandwiches to perfection, while maintaining the integrity of the ingredients, allowed the café to offer a wide range of unique sandwiches that kept customers coming back for more. The consistent quality of the sandwiches, thanks to the reliable equipment, helped solidify the café’s reputation as a gourmet haven.

Another story comes from a bustling food court within a busy shopping center. A food vendor there decided to specialize in wraps and sandwiches. By investing in a versatile sandwich maker that could also accommodate wraps, they were able to cater to a broader customer base. The machine’s efficiency allowed them to prepare large volumes of food quickly, ensuring that customers in a hurry could still enjoy a fresh and delicious meal. The vendor’s success was not just in the speed of service but also in the satisfaction of their customers, who appreciated the freshness and quality of the sandwiches.

In the realm of fast-food franchises, a well-known chain faced a challenge when it came to maintaining the quality of their sandwiches across all locations. The introduction of a commercial sandwich machine with consistent heating elements solved this issue. The machine ensured that every sandwich was cooked to the same temperature, with the perfect balance of crispiness and softness. This uniformity in quality became a hallmark of the brand, and customers began to associate the franchise with a reliable and delicious meal, regardless of where they were.

A mobile catering service also saw a significant boost in their operations with the right sandwich equipment. A portable sandwich press allowed them to prepare sandwiches on-site for events, weddings, and festivals. The convenience of the machine meant they could serve hot, freshly made sandwiches to large crowds without delay. The positive feedback from event organizers and guests turned the catering service into a sought-after provider, enhancing their reputation and business opportunities.

Lastly, a small local deli used a custom-built sandwich machine to cater to their unique menu. The machine was designed to accommodate their signature sandwiches, which required a special method of toasting and filling. This tailored solution allowed the deli to offer their classic dishes with the same consistency and quality, even as their business grew. The deli’s commitment to tradition and quality, made possible by the perfect sandwich equipment, earned them a loyal following and a place in the hearts of the local community.

These success stories are just a glimpse into how the right sandwich equipment can make all the difference in a commercial kitchen. From enhancing speed and efficiency to maintaining consistent quality, the right machine can be the cornerstone of a thriving business.

In the ever-evolving world of foodservice, the art of sandwich making is witnessing a remarkable transformation. Innovation and efficiency are at the forefront, shaping the future of this beloved culinary staple. From high-tech automation to sustainable materials, the landscape of sandwich making is poised to change in exciting ways.

The integration of technology into sandwich preparation is not just about speed; it’s about precision and consistency. Automated machines are now capable of slicing, toasting, and spreading condiments with unparalleled accuracy, ensuring that every sandwich served is as uniform as the last. This level of control over the sandwich-making process is crucial for maintaining brand standards across multiple locations, whether it’s a bustling café or a large-scale food service operation.

Energy efficiency has become a key consideration in the design of modern sandwich machines. With the growing emphasis on sustainability, manufacturers are focusing on reducing energy consumption. This shift is evident in the use of advanced heating elements that heat up quickly and maintain consistent temperatures, minimizing energy waste. Additionally, some machines now come with features that automatically shut off when not in use, further cutting down on energy costs.

Customization is another area where innovation is making a significant impact. Customers today demand a high degree of personalization, and sandwich machines are responding with programmable settings that allow for a wide range of fillings, bread types, and cooking temperatures. This flexibility means that businesses can cater to diverse tastes and dietary preferences, from vegan to gluten-free options, all on the same machine.

The advent of smart sandwich machines has also brought about a new level of convenience. These machines can be integrated with restaurant management systems, allowing for real-time monitoring and predictive maintenance. This not only helps in maintaining optimal performance but also ensures that downtime is minimized, keeping the sandwich line running smoothly.

The use of high-quality, durable materials in the construction of sandwich machines is also a testament to the industry’s commitment to innovation. Machines are now being built with stainless steel components that are not only resistant to corrosion but also easy to clean, which is crucial in maintaining food safety standards. The adoption of these materials also extends the lifespan of the equipment, reducing the need for frequent replacements.

Sustainability is at the heart of the future of sandwich making. Eco-friendly practices are being embraced, from the sourcing of raw materials to the end-of-life disposal of machines. Some manufacturers are now using recycled materials in the production of sandwich machines, and others are designing them for disassembly and recycling at the end of their service life.

Health and safety are also driving innovation in sandwich making. New features are being developed to reduce the risk of cross-contamination, especially important in environments where allergies are a concern. This includes touchless operation and advanced cleaning systems that sanitize the machine between uses.

Lastly, the future of sandwich making is about creating an experience for the consumer. The integration of interactive screens and digital menus is becoming more common, allowing customers to select their preferences and watch their sandwich being made. This level of engagement can elevate the sandwich from a simple meal to a memorable dining experience.

In conclusion, the future of sandwich making is marked by a relentless pursuit of innovation and efficiency. As the industry continues to evolve, the end result is a more tailored, sustainable, and enjoyable dining experience for consumers, all made possible by the advancements in sandwich machine technology.

Navigating the sandwich-making scene, it’s clear that the heart of any commercial kitchen lies in the equipment that powers it. Here’s how to pinpoint the best sandwich machine manufacturer that aligns with your needs:

In the bustling world of fast-casual dining, a sandwich machine can be the silent hero that keeps lines moving and orders flowing. The right machine can mean the difference between a smooth operation and a kitchen in disarray.

Consider the variety of sandwich machines available on the market. From compact countertop models to large-scale industrial units, each is designed to cater to different kitchen environments and volume demands. A smaller, portable unit might be ideal for a café or a food truck, while a robust, high-capacity machine is essential for a busy restaurant or a food court.

Quality and durability are non-negotiable when it comes to commercial kitchen equipment. Look for manufacturers that offer a solid track record of producing machines that withstand the rigors of daily use. Machines made with high-quality materials and precision engineering are less likely to break down, saving you time and money on repairs and replacements.

The efficiency of a sandwich machine is a crucial factor in maintaining a high level of service. A machine that can prepare sandwiches quickly and consistently will keep your kitchen running smoothly and your customers satisfied. Features like adjustable settings for different types of bread and fillings, as well as rapid heating elements, can significantly enhance productivity.

In the age of health consciousness, the ability to customize sandwiches is more important than ever. A reliable sandwich machine manufacturer will offer a range of options that allow for easy adjustments to accommodate dietary restrictions and preferences. This flexibility can be a game-changer for businesses looking to cater to a diverse clientele.

Customer service and support are often overlooked but are vital to the success of any business. A manufacturer that provides excellent customer service can be a lifesaver when you encounter issues with your equipment. Look for companies with a strong reputation for responsiveness, offering everything from troubleshooting tips to on-site repairs.

Testimonials and case studies can be invaluable in making your decision. Take the time to read what other businesses have to say about their experiences with different manufacturers. A company with numerous positive reviews and satisfied customers is likely to be a solid choice.

Keep in mind that the cost of a sandwich machine isn’t just about the initial investment. Consider the long-term costs, including maintenance, energy consumption, and the potential for repairs or upgrades. A higher-quality machine might have a steeper upfront cost, but it could save you money in the long run with lower operating costs and a longer lifespan.

Don’t underestimate the importance of after-sales service. A manufacturer that offers comprehensive support, including training, parts, and maintenance, can help ensure that your sandwich machine remains in top condition for years to come.

Lastly, consider the brand’s commitment to innovation. A manufacturer that continuously invests in research and development to improve their products is likely to offer you the most advanced and efficient sandwich-making solutions.

In conclusion, finding the best sandwich machine manufacturer for your needs involves a careful evaluation of the machine’s features, the manufacturer’s reputation, customer service, and the overall value proposition. By taking these factors into account, you can make an informed decision that will serve your business well for years to come.