Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In recent years, Vietnam has quietly transformed itself into a powerhouse in the sandwich machine manufacturing industry, capturing the attention of foodservice operators worldwide. This article delves into the journey of this burgeoning sector, exploring the factors that have propelled Vietnam to the forefront of sandwich machine production.

Vietnam has emerged as a significant player in the sandwich machine manufacturing industry. With a growing number of companies specializing in this niche, the country has seen a surge in the production and export of these innovative devices.

The sandwich machine market in Vietnam is diverse, catering to both domestic and international demand. From small-scale bakeries to large food processing plants, these machines are essential for producing a variety of food products efficiently.

As the culinary landscape evolves, Vietnamese manufacturers are adapting their machines to meet the latest trends in the food industry. This includes the ability to create a wide range of sandwiches, from traditional to gourmet options.

The Vietnamese sandwich machine industry is known for its competitive pricing and high-quality components. This combination makes the country’s products highly sought after in the global market.

In recent years, there has been a significant investment in research and development, ensuring that Vietnamese sandwich machines are not only efficient but also durable and user-friendly.

The rise of sandwich machine manufacturing in Vietnam is a story of both adaptation and innovation. Once a country known for its agricultural output, Vietnam has successfully diversified its industrial base, with food processing becoming a major sector.

As demand for quick-service restaurants grew, so too did the need for efficient sandwich-making machines. This demand sparked a boom in local production, with a variety of manufacturers springing up across the nation.

Government initiatives and favorable policies have played a crucial role in supporting this growth, offering incentives for local entrepreneurs to invest in food processing technology and machinery.

The increase in foreign direct investment (FDI) has also bolstered the sector, bringing in international expertise and technology that has helped Vietnamese manufacturers raise their standards and compete on the global stage.

This rise hasn’t been without its challenges. The industry has had to navigate quality control issues and meet international safety standards, but the progress made is undeniable.

Now, Vietnam stands as a notable exporter of sandwich machines, with its products gaining popularity worldwide due to their affordability and reliability.

Vietnam’s position as a leading sandwich machine manufacturer can be attributed to several key factors. One of the most notable is the country’s skilled workforce, which has a reputation for precision and craftsmanship.

The cost of labor in Vietnam is also a significant advantage. This lower labor cost translates to more competitive pricing for sandwich machines, making them an attractive option for businesses around the world.

Innovation is at the heart of Vietnam’s success in this industry. Local manufacturers are known for their ability to develop machines that are both efficient and adaptable to various food production needs.

Additionally, the supply chain in Vietnam is robust, with a network of suppliers that can provide the necessary components and materials to support the production of high-quality sandwich machines.

Government support has been instrumental in fostering the growth of the sandwich machine industry. Policies that encourage foreign investment and technology transfer have helped Vietnamese manufacturers stay at the forefront of innovation.

Lastly, the global reach of Vietnamese companies has been expanding, with their machines now found in numerous countries, testament to the brand reputation and quality associated with Vietnamese sandwich machine manufacturing.

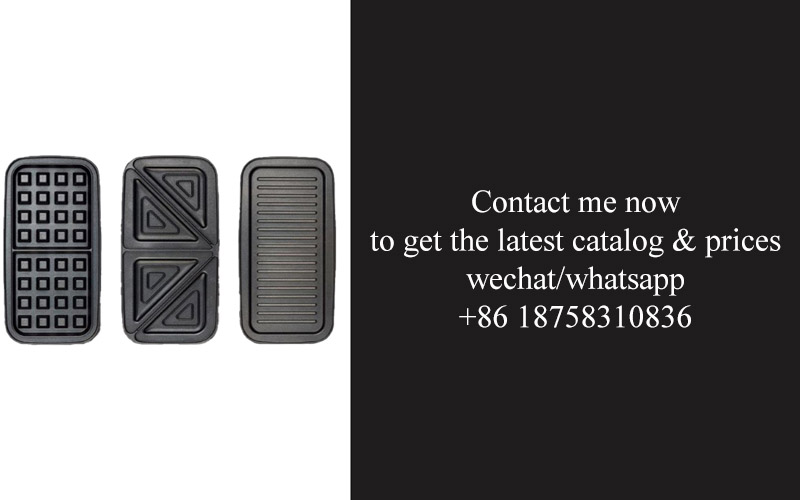

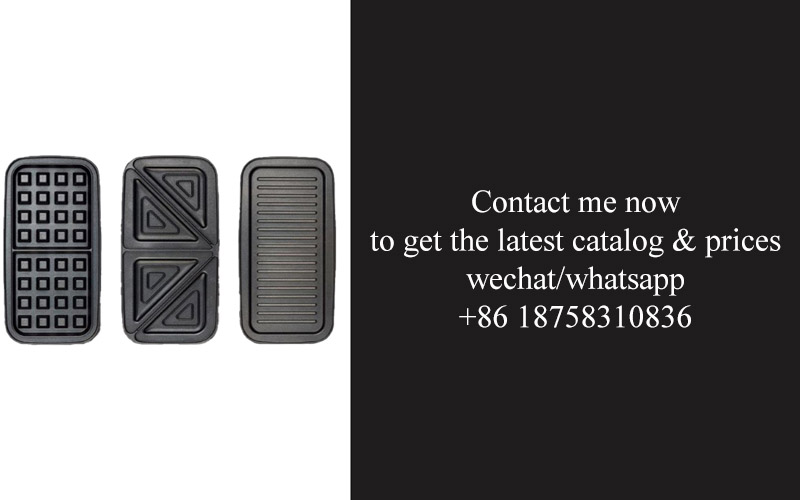

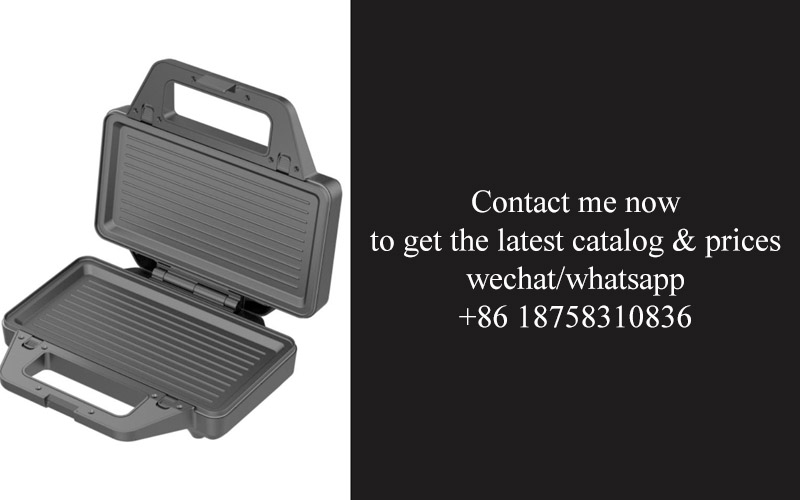

Vietnamese sandwich machine manufacturers are known for their innovative designs that cater to the evolving needs of the food industry. These designs often feature advanced technology, such as automated systems that streamline the sandwich-making process.

Quality assurance is a cornerstone of Vietnam’s sandwich machine industry. Manufacturers implement strict quality control measures at every stage of production, from raw material selection to the final assembly.

Regular maintenance and service options are also integrated into the design of these machines, ensuring they remain reliable and efficient over their lifespan.

The use of high-grade materials in the construction of these machines not only enhances their durability but also contributes to their overall performance and hygiene standards.

Innovation isn’t just about new features; it’s also about making machines more accessible and user-friendly. Vietnamese manufacturers are continuously working on interfaces and controls that are intuitive for operators of all skill levels.

Finally, the commitment to ongoing research and development means that Vietnamese sandwich machines are consistently improving, offering the latest in food production technology.

Vietnamese sandwich machines have made a significant mark on the global market, offering a competitive edge to businesses worldwide. Their affordability has made them a favorite among small to medium-sized foodservice operations.

The reliability of these machines has been a game-changer, with many operators reporting reduced downtime and increased productivity, leading to higher profit margins.

The versatility of Vietnamese sandwich machines has allowed them to be used in a variety of settings, from fast-food chains to gourmet cafes, broadening their appeal across different market segments.

The global presence of Vietnamese sandwich machine brands has been strengthened by strategic partnerships and distribution networks, ensuring widespread availability and support.

Customers have also been impressed by the ease of maintenance and the availability of replacement parts, which has further solidified the reputation of Vietnamese machines on the international stage.

The impact of Vietnamese sandwich machines is not just seen in sales figures; it’s also reflected in the innovation and quality that these machines bring to the global foodservice industry.

Vietnamese sandwich machine manufacturers are increasingly focusing on sustainability, incorporating eco-friendly practices into their production processes.

Efforts are being made to use recyclable materials and energy-efficient components in the construction of these machines, reducing the environmental footprint.

Manufacturers are also designing products that are easier to disassemble and recycle at the end of their life cycle, promoting a circular economy.

The industry is adopting green energy solutions, such as solar panels and wind turbines, to power their factories, further minimizing carbon emissions.

Innovation isn’t just about technological advancements; it’s also about sustainable practices that include responsible sourcing and waste management.

By prioritizing these eco-friendly approaches, Vietnamese sandwich machine companies are not only reducing their impact on the environment but also setting a positive example for the industry at large.

One bakery owner in London praised the Vietnamese sandwich machine for its speed and consistency, noting that it has significantly boosted their sandwich production.

A café in Paris shared how the machine’s ease of use has allowed their staff to focus more on customer service, enhancing the overall dining experience.

A food truck operator in the USA mentioned that the compact design of the Vietnamese sandwich machine has been perfect for their mobile business, providing a seamless service to their customers.

A large-scale food processing plant in Germany highlighted the machine’s durability and the cost savings it has brought to their operation.

Several customers have commented on the exceptional customer service provided by Vietnamese manufacturers, who are quick to respond to inquiries and provide technical support.

Vietnam’s sandwich machine manufacturing industry is poised for continued growth, driven by technological advancements.

The integration of smart technology and automation is expected to further streamline production processes and increase efficiency.

There’s a growing emphasis on research and development, with Vietnamese manufacturers aiming to create machines that are not just efficient but also sustainable.

The industry is also looking to expand its global reach, targeting emerging markets where there’s a high demand for affordable, high-quality food processing solutions.

Collaborations with international partners could lead to new innovations and the adoption of global best practices within the Vietnamese industry.

As consumer preferences shift towards healthier and more diverse food options, Vietnamese manufacturers are likely to adapt their machines to cater to these trends.

Vietnam’s emergence in the sandwich machine manufacturing sector is a testament to the nation’s industrial evolution. The country has leveraged its strengths to become a key player in this niche market.

From humble beginnings, Vietnamese manufacturers have risen to offer a wide array of sandwich machines that are now sought after globally.

The commitment to quality, innovation, and sustainability has positioned Vietnam as a reliable source for sandwich machine solutions.

The future looks promising as Vietnam continues to invest in technology and expand its presence in the international market.