Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where convenience and speed are paramount, the art of sandwich making has evolved beyond the simple act of piling ingredients between slices of bread. Sandwich machines have emerged as a pivotal tool in the food service industry, reshaping the way we think about fast and fresh meals. These innovative devices have not only streamlined the process of crafting sandwiches but have also introduced a new wave of creativity in the culinary world. Let’s delve into the intricacies of these sandwich-making marvels and explore the factors that define their role in various markets, the qualities to seek in a manufacturer, and the exciting possibilities that lie ahead in the future of sandwich making.

The world of fast food has seen a whirlwind of innovation, and one of the most significant advancements is the rise of sandwich machines. These automated wonders have become a game-changer, transforming the way we think about quick and delicious meals. With the hustle and bustle of modern life, convenience has become a top priority, and sandwich machines are at the forefront of this convenience revolution.

Once confined to the realms of high-end delis and gourmet eateries, these machines have now found their way into the heart of fast-food franchises, cafes, and even schools and hospitals. The reasons for this meteoric rise are many, but let’s delve into some of the key factors that have propelled sandwich machines to stardom.

Firstly, the convenience factor cannot be overstated. In the fast-paced world we live in, customers are looking for meals that can be whipped up quickly without sacrificing taste. Sandwich machines allow for the production of freshly made sandwiches in mere minutes, ensuring that customers can grab their lunch or breakfast on the go without waiting in long lines.

Secondly, the versatility of these machines is remarkable. They can handle a wide variety of ingredients, from the simplest of ham and cheese to the most exotic combinations of meats, vegetables, and spreads. This flexibility means that sandwich machines can cater to diverse tastes and dietary preferences, making them a hit with both the general public and health-conscious consumers.

Moreover, the consistency that sandwich machines provide is unparalleled. Each sandwich comes out with the same level of freshness and quality, thanks to the precise controls and automated processes. This reliability is something that traditional sandwich preparation cannot match, and it has won over many food service operators who value a consistent product.

Another crucial aspect of sandwich machines is their efficiency. They can churn out sandwiches at a rate that would be impossible for even the most skilled sandwich artist. This efficiency translates into higher productivity and reduced labor costs for businesses, making them a cost-effective investment.

The technology behind sandwich machines has also seen considerable advancements. Modern machines are equipped with features like variable heat settings, adjustable pressure controls, and even the ability to customize the size and shape of the sandwiches. These innovations not only enhance the quality of the final product but also open up new possibilities for creative sandwich designs.

In addition to the benefits for food service providers, sandwich machines have also made a significant impact on the customer experience. The ease of use and speed of service have been shown to increase customer satisfaction, leading to higher repeat business and word-of-mouth referrals.

The environmental impact of sandwich machines is another factor that cannot be overlooked. By reducing the need for disposable packaging and minimizing food waste, these machines contribute to a more sustainable approach to food service. This eco-friendly aspect has become increasingly important to consumers and businesses alike.

The global market for sandwich machines has seen rapid growth, with manufacturers from various corners of the world jumping on the bandwagon. From Europe to Asia, sandwich machine manufacturers are constantly pushing the boundaries of innovation, offering cutting-edge technology and high-quality products to meet the demands of the fast-food industry.

As the demand for quick, quality meals continues to grow, the role of sandwich machines is set to become even more prominent. With the ability to adapt to new trends and consumer preferences, these machines are not just a fleeting trend but a lasting solution to the need for efficient and delicious food service.

In conclusion, the rise of sandwich machines has been nothing short of transformative in the fast-food industry. Their convenience, versatility, efficiency, and innovative design have all contributed to their skyrocketing popularity. As we continue to seek out ways to improve our lives and streamline our daily routines, sandwich machines are poised to remain a staple in the quest for quick and satisfying meals.

In the competitive world of foodservice equipment, certain sandwich machine manufacturers have stood out for their innovation, reliability, and quality. Here’s a look at some of the top names in the industry:

GourmetsmithGourmetsmith has become synonymous with excellence in sandwich preparation. Known for their high-quality, commercial-grade sandwich makers, they offer a variety of models that cater to everything from quick-service restaurants to fine dining establishments. Their machines are designed to ensure even heat distribution and precise toasting, resulting in consistently perfect sandwiches.

Chef’nChef’n has made a name for itself by focusing on user-friendly designs and affordability. Their sandwich makers are perfect for small cafes, delis, and even home kitchens. Chef’n’s commitment to eco-friendly materials and durable construction means that their products are not only easy to use but also long-lasting.

Hamilton BeachA household name in kitchen appliances, Hamilton Beach has expanded its offerings to include commercial sandwich machines. Their products are known for their robust build and ease of maintenance, making them a popular choice for food trucks, concession stands, and busy coffee shops.

Waring CommercialWaring Commercial is renowned for its commercial-grade equipment, and their sandwich machines are no exception. With a focus on durability and performance, Waring’s machines are designed to handle high-volume production without compromising on the quality of the sandwiches. They are a go-to for busy restaurants and caterers.

BrevilleBreville, while often associated with home appliances, has also entered the commercial market with their sandwich makers. Their sleek designs and high-quality materials are a testament to the brand’s commitment to innovation. Breville’s machines are favored for their ability to produce a wide range of sandwich options, from simple ham and cheese to gourmet creations.

KenyonKenyon is a leader in the sandwich equipment industry, offering a comprehensive range of sandwich makers suitable for various types of foodservice operations. Their machines are engineered for speed and efficiency, ensuring that even the busiest kitchens can maintain a steady supply of fresh, hot sandwiches.

APW WyottAPW Wyott is known for its durable and versatile commercial kitchen equipment. Their sandwich machines are built to withstand the rigors of constant use, making them a reliable choice for high-traffic establishments. APW Wyott’s attention to detail in design and functionality is evident in the seamless operation of their machines.

TurboChefTurboChef’s sandwich makers are known for their speed and efficiency. Ideal for quick-service restaurants, these machines can prepare sandwiches in a fraction of the time it would take by hand. TurboChef’s commitment to energy efficiency and eco-friendly practices is also a significant draw for many operators.

Rival CommercialRival Commercial offers a range of sandwich makers that are perfect for those who want a balance of quality and value. Their machines are built to last, with features that ensure even heating and a crisp, golden-brown finish on sandwiches of all kinds.

ToastmasterToastmaster’s commercial sandwich makers are a favorite among foodservice professionals. They offer a variety of models to suit different needs, from countertop units to conveyor ovens. Toastmaster’s reputation for excellence in design and performance continues to make them a top choice for businesses of all sizes.

These manufacturers have proven time and again that they can deliver high-quality sandwich machines that not only meet but exceed the demands of the modern foodservice industry. Whether it’s for a bustling café or a fine dining establishment, these brands are known for their commitment to quality, innovation, and customer satisfaction.

In the bustling world of foodservice, the quality of sandwich machine supply is a cornerstone that can make or break a business. The right machine not only ensures consistent and efficient service but also reflects the brand’s commitment to quality. Here’s why quality in sandwich machine supply matters:

Precision in ProductionThe precision with which a sandwich machine is crafted is paramount. High-quality machines are often made with precision engineering, ensuring that every component fits seamlessly. This level of craftsmanship means that the machine can handle various bread types, fillings, and condiments with ease, producing uniform sandwiches every time.

Durability and ReliabilityA quality sandwich machine is built to last. It’s designed with robust materials that can withstand heavy use, reducing the frequency of breakdowns and maintenance. This reliability is crucial for busy restaurants and cafes where downtime can lead to lost sales and dissatisfied customers.

Customization and FlexibilityTop-tier sandwich machine manufacturers understand that one size does not fit all. They offer a range of models that can be customized to meet specific needs, whether it’s the size of the sandwiches, the type of bread, or the speed of production. This flexibility allows businesses to tailor their equipment to their unique operations.

Ease of MaintenanceQuality in sandwich machine supply extends beyond the initial purchase. High-quality machines are designed with easy maintenance in mind. Accessible parts, clear instructions, and reliable components make it simpler for staff to perform routine maintenance, ensuring the machine remains in top condition for years.

Health and Safety ComplianceIn the food industry, health and safety are non-negotiable. Quality sandwich machines are constructed with hygiene in mind, featuring easy-to-clean surfaces and components that prevent cross-contamination. Compliance with food safety standards not only protects customers but also minimizes the risk of costly recalls or legal issues.

Cost-EffectivenessWhile high-quality sandwich machines may have a higher upfront cost, they can be more cost-effective in the long run. With fewer repairs and replacements needed, businesses can save money over time. Additionally, the efficiency and consistency these machines provide can lead to increased sales and customer satisfaction, which can be a significant return on investment.

Innovation and FeaturesManufacturers of quality sandwich machines are constantly innovating, adding features that improve functionality and efficiency. These may include programmable settings for different types of sandwiches, adjustable heating elements for perfect browning, or even built-in analytics to monitor performance and maintenance needs.

Customer Support and ServiceA quality sandwich machine manufacturer stands behind their product with excellent customer support. From installation and training to troubleshooting and spare parts, reliable customer service ensures that any issues are addressed promptly. This level of support can be the difference between a machine that simply works and one that becomes an integral part of a successful business.

In summary, the quality of sandwich machine supply is essential for any establishment looking to serve great sandwiches. From the precision of its construction to the longevity of its use, the right machine can elevate the customer experience and the bottom line. Investing in quality is investing in the future of your business.

In the bustling world of food service, efficiency is king. Sandwich machines have emerged as a cornerstone in this quest for speed and consistency. These innovative devices are not just about slapping together a quick meal; they are revolutionizing the way food is prepared and served. Let’s delve into how these machines are enhancing efficiency across the industry.

The Time-Saving AspectSandwich machines streamline the preparation process by automating many of the steps that traditionally take time. From toasting the bread to adding fillings, these machines can produce a perfectly grilled sandwich in mere minutes. This rapid production slashes wait times for customers, ensuring that the line moves swiftly and queues are kept to a minimum.

Consistency Across the BoardOne of the greatest strengths of sandwich machines is their ability to maintain a high level of consistency. No matter how many orders are placed, these machines can churn out sandwiches with the same level of quality each time. This is crucial in food service, where customer expectations are high and the reputation of a restaurant or café hinges on the reliability of its offerings.

Customization Without CompromiseWhile consistency is key, the ability to customize orders is equally important. Sandwich machines often come with features that allow for a variety of toppings and fillings to be added with ease. This means that customers can enjoy their preferred sandwich without the wait, as the machine adjusts to their specific requests without slowing down the process.

Reduced Labor RequirementsThe efficiency of sandwich machines also translates to a reduction in labor needs. While a skilled chef can certainly prepare a sandwich with care, the speed and reliability of these machines mean that fewer staff members are required to handle the sandwich-making process. This not only reduces labor costs but also frees up staff to focus on other aspects of service, such as customer interaction and cleaning.

Enhanced CapacityIn high-traffic areas, the capacity to serve a large number of customers simultaneously is invaluable. Sandwich machines can be strategically placed to cater to a steady flow of orders, ensuring that the kitchen remains productive even during peak hours. This increased capacity allows businesses to handle rushes without sacrificing the quality or speed of service.

Streamlined WorkflowThe integration of sandwich machines into the workflow of a food service establishment is seamless. These machines are designed to fit into existing kitchen layouts and can often be programmed to match the specific needs of the business. This means that operators can optimize their production lines to maximize output while minimizing downtime.

Quality Control in Every BatchWith a sandwich machine, quality control is no longer a concern that requires constant oversight. The machine ensures that every sandwich is made to the same standard, reducing the risk of errors and the need for manual checks. This not only saves time but also ensures that customers receive a product that meets or exceeds their expectations.

Improved Customer SatisfactionUltimately, the efficiency brought about by sandwich machines leads to improved customer satisfaction. When customers are served quickly and receive a high-quality product, they are more likely to return. In a competitive market, this can be a significant differentiator for businesses looking to build a loyal customer base.

In conclusion, sandwich machines have become an indispensable tool in the food service industry. Their ability to save time, maintain consistency, and reduce labor requirements while enhancing capacity and customer satisfaction makes them a vital component in the quest for efficiency. As technology continues to evolve, it’s likely that these machines will become even more sophisticated, further shaping the future of food service.

In the fast-paced world of food service, sandwich machines have not only become a staple in quick-service restaurants but have also evolved through innovative design. These advancements are reshaping the way sandwiches are made, offering both speed and quality. Here’s a look at some of the latest innovations in sandwich machine design:

The integration of smart technology has revolutionized the way sandwich machines operate. Modern models now come equipped with touchscreens that allow for easy programming of various sandwich recipes. This not only simplifies the operation for staff but also ensures consistency in the final product, as every sandwich is made to precise specifications.

One of the most significant innovations is the ability to customize sandwiches with a high degree of precision. Modern sandwich machines can accommodate different bread sizes, crust options, and a variety of fillings. This flexibility allows for a wider variety of menu offerings, catering to diverse tastes and dietary preferences. The ability to add fresh ingredients like lettuce, tomatoes, and condiments directly into the machine streamlines the process and reduces waste.

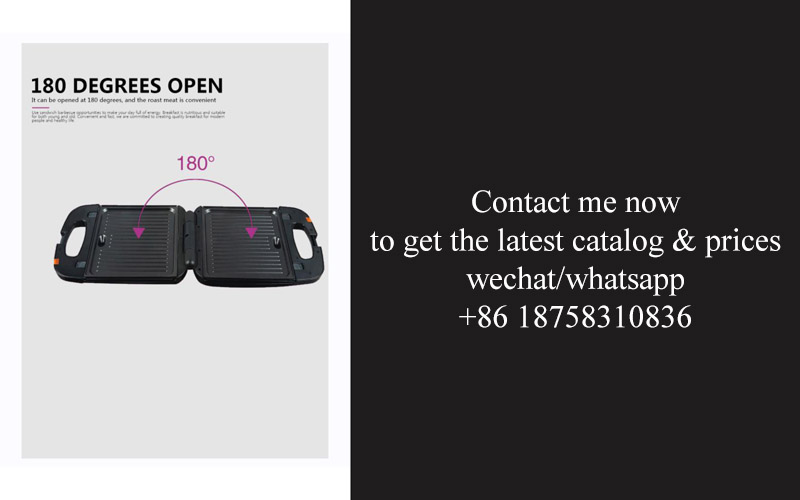

The design of sandwich machines has also focused on speed and efficiency. Newer models are equipped with high-speed toasters that can brown bread to perfection in seconds, while also ensuring that the heat is evenly distributed. The use of automated feeding systems means that operators can load multiple slices of bread and fillings into the machine, which then assembles and cooks them in a fraction of the time it would take by hand.

Safety has always been a priority in food service, and sandwich machine design has not overlooked this aspect. Modern machines are built with features like automatic shut-off, which activate if the machine is left unattended or if a sensor detects a blockage. This not only prevents fires but also reduces the risk of accidents in busy kitchens.

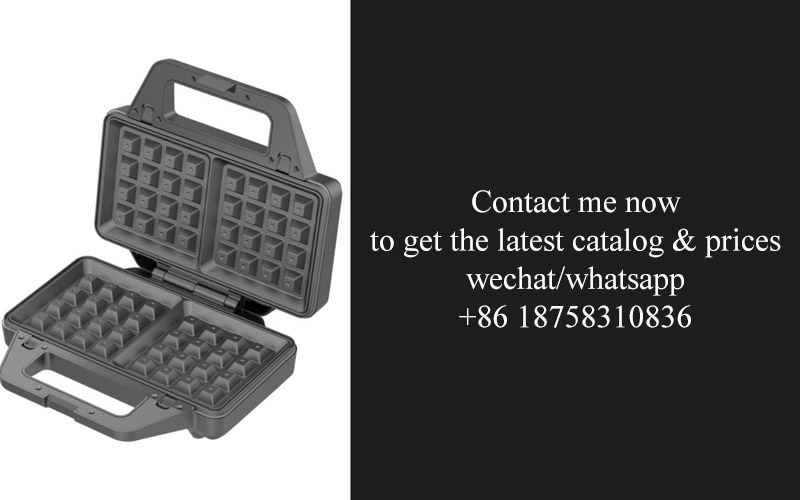

Another innovative aspect is the incorporation of modular designs. Sandwich machines can now be customized with various attachments and accessories, such as flatbread toasters, panini presses, or even waffle makers. This modular approach allows restaurants to adapt their machines to the specific needs of their menu, whether they’re serving traditional sandwiches, wraps, or even breakfast items.

Energy efficiency has also become a key consideration in sandwich machine design. Manufacturers are now producing machines that consume less energy, which not only reduces operational costs but also has a positive impact on the environment. The use of energy-saving elements and smart heating controls means that machines can heat up quickly and maintain consistent temperatures without excessive energy use.

In the realm of sanitation, sandwich machines have seen advancements that make cleaning easier and more effective. Non-stick surfaces and removable parts simplify the cleaning process, reducing the risk of cross-contamination and ensuring that machines can be sanitized quickly and thoroughly.

The design of sandwich machines has also embraced sustainability, with some models now made from recyclable materials. This eco-friendly approach not only aligns with the values of environmentally conscious consumers but also reduces the carbon footprint of food service operations.

Lastly, the user interface has seen a significant transformation. Modern sandwich machines feature intuitive interfaces that can be easily learned by staff, even those without technical expertise. This means that operators can spend less time on training and more time focusing on customer service.

In conclusion, the innovations in sandwich machine design reflect a commitment to speed, efficiency, customization, safety, and sustainability. As the food service industry continues to evolve, these advancements ensure that sandwich machines remain a reliable and versatile tool for any establishment looking to serve high-quality sandwiches quickly and consistently.

In today’s fast-paced food service industry, sandwich machines have become an essential tool for streamlining operations and satisfying customer demand. These versatile machines play a crucial role across various markets, from bustling urban cafes to busy corporate canteens. Here’s a closer look at the diverse applications of sandwich machines in different markets.

1. Quick Service Restaurants (QSRs)Quick service restaurants rely heavily on speed and consistency to keep their customers happy. Sandwich machines are a staple in these establishments due to their ability to produce high-quality sandwiches quickly. The ability to customize sandwiches to individual preferences without a lengthy wait time is a significant draw for busy diners who are looking for a quick, yet satisfying meal.

2. Convenience StoresConvenience stores are often the go-to spot for those needing a quick bite on the go. These stores are perfect locations for sandwich machines because they cater to customers with limited time and a desire for a hot, freshly made meal. The compact size of many sandwich machines also makes them an ideal fit for tight store layouts, maximizing space for other essential items.

3. Hospitals and Healthcare FacilitiesIn healthcare environments, time is critical, and sandwich machines provide a convenient way for patients and staff to access nutritious, homemade meals. These machines can be easily cleaned and sanitized, making them ideal for maintaining hygiene standards in a setting where health and safety are paramount.

4. Airports and Train StationsTravelers looking for a quick meal at airports or train stations appreciate the convenience of sandwich machines. These machines can be found in terminals or platforms, offering a variety of sandwich options that are both satisfying and easy to eat. Their ability to maintain a high pace of production ensures that even during peak travel times, travelers can find a meal without a long wait.

5. Corporate CafeteriasCorporate cafeterias often cater to a diverse workforce with varying tastes and dietary requirements. Sandwich machines offer a solution that can accommodate a range of preferences, from classic ham and cheese to vegetarian or vegan options. They can also be used to create specialty sandwiches for promotional events or as part of a diverse menu that reflects the company’s commitment to employee well-being.

6. Schools and UniversitiesEducational institutions are constantly looking for ways to provide nutritious meals for students and staff. Sandwich machines offer a quick and efficient way to serve a variety of sandwiches, from classic PB&J to hearty wraps. They also facilitate the implementation of healthy eating programs by allowing schools to offer a range of whole-grain, protein-rich options.

7. Sports Venues and Event CentersSports fans and attendees at large events often seek out quick, on-site food options. Sandwich machines can be strategically placed around arenas and stadiums to serve thousands of hungry patrons efficiently. The ability to customize sandwiches and quickly replenish popular items ensures that no one has to miss the game or event because of a long wait for food.

8. Cruise Ships and FerriesOnboard cruise ships and ferries, where space is limited but demand for food is high, sandwich machines are invaluable. They provide a consistent supply of sandwiches that can be stored and served with minimal need for refrigeration or storage space. The versatility of these machines allows for a wide range of options, from breakfast sandwiches to late-night snacks.

9. Catering ServicesCatering services often need to cater to large groups with varying dietary needs. Sandwich machines can be a game-changer here, allowing caterers to produce a large volume of sandwiches in various styles and flavors quickly. This capability is particularly useful for outdoor events, festivals, and conferences where mobility and speed are essential.

10. International MarketsIn international markets, the demand for fast and convenient food continues to grow. Sandwich machines have become a universal solution, bridging cultural gaps by providing a familiar food option that can be customized to suit local tastes. From Japan to the United States, these machines are an integral part of the global foodservice industry.

The role of sandwich machines in these diverse markets underscores their adaptability and efficiency. They offer a simple yet effective solution for foodservice providers looking to enhance their menu offerings and cater to the fast-paced lifestyle of today’s consumers. Whether in a bustling city or a remote location, sandwich machines are proving to be a staple in the foodservice industry, contributing to the satisfaction and convenience of customers around the world.

When selecting a sandwich machine manufacturer, it’s crucial to consider several factors to ensure you’re getting a reliable and high-quality product. Here’s what to keep an eye out for:

Quality ComponentsThe foundation of a great sandwich machine lies in its components. Look for manufacturers that use top-notch materials like stainless steel for durability and hygiene. Components should be precision-engineered to ensure seamless operation and longevity.

Customization OptionsNo two businesses are alike, and your sandwich machine should reflect that. A good manufacturer offers customization options, allowing you to tailor the machine to your specific needs, whether it’s adjusting the size of the sandwiches or integrating additional features.

Customer SupportA reliable manufacturer understands that equipment can sometimes break down or require maintenance. They should offer comprehensive customer support, including timely repairs, spare parts availability, and training for staff on how to use the machine effectively.

User-Friendly DesignA sandwich machine is only as good as its usability. Choose a manufacturer that focuses on creating user-friendly designs. Features like intuitive interfaces, clear instructions, and easy-to-clean surfaces can greatly enhance the efficiency of your kitchen staff.

Innovation and TechnologyThe sandwich-making industry is constantly evolving. A forward-thinking manufacturer keeps up with the latest innovations and technologies. Look for features like programmable settings, adjustable heating elements, and automated systems that can streamline your sandwich-making process.

Warranty and After-Sales ServiceA solid warranty is a sign of a manufacturer’s confidence in their product. Ensure the manufacturer offers a robust warranty and reliable after-sales service. This way, if any issues arise, you know you have a reliable partner to address them promptly.

Safety FeaturesSafety should never be compromised, especially in a busy kitchen environment. A reputable manufacturer incorporates safety features into their sandwich machines, such as automatic shut-offs, temperature controls, and emergency stop mechanisms.

Energy EfficiencyRunning a kitchen can be expensive, and energy costs are a significant factor. Opt for a sandwich machine manufacturer that emphasizes energy efficiency. Machines that use less power can help reduce your overall operational costs.

Certifications and StandardsA manufacturer that adheres to industry standards and certifications demonstrates a commitment to quality and safety. Look for machines that meet health and safety regulations, such as those from the FDA or CE marking.

Testimonials and ReviewsBefore making a decision, do your homework. Check out customer testimonials and reviews online. Real-world experiences from other businesses can provide valuable insights into the manufacturer’s reputation and the performance of their machines.

Pricing and ValueWhile price is a consideration, it’s not the only one. Consider the overall value you’re getting for your investment. A higher-quality machine that pays for itself through efficiency and longevity might be more cost-effective in the long run.

Local Availability and SupportIf possible, choose a manufacturer that has a presence in your local area. This can mean faster response times for service and support, as well as a better understanding of the local market’s needs.

Longevity and ReputationThe longevity of a manufacturer often reflects the quality of their products. A company with a long-standing reputation in the industry is likely to provide you with a sandwich machine that will serve you well over time.

In summary, when choosing a sandwich machine manufacturer, it’s important to consider the quality of the components, customization options, customer support, design, technology, safety, energy efficiency, certifications, customer reviews, pricing, local availability, and reputation. Taking these factors into account will help you select a machine that not only meets your immediate needs but also supports the growth and success of your business.

In a world where innovation meets convenience, the future of sandwich making is an exciting frontier. As technology advances, the way we create and enjoy sandwiches is poised to evolve. Here’s a glimpse into what might be coming:

The Integration of TechnologyWe’re already seeing a blend of technology and foodservice, but the future could see even more sophisticated integration. Imagine a sandwich machine that not only assembles but also customizes your sandwich based on your dietary preferences, all with a touch of a button. Sensors could detect ingredients and portion sizes, ensuring each sandwich is perfectly balanced and tailored to individual tastes.

Sustainability and Eco-Friendly DesignsWith environmental concerns at the forefront, the future of sandwich making may lean heavily on sustainable practices. Machines might be designed with eco-friendly materials, using less energy and producing minimal waste. The use of biodegradable materials for components and packaging could become standard, reducing the sandwich-making industry’s carbon footprint.

Interactive and Connected MachinesThe future could bring us sandwich machines that are part of a larger network, offering real-time data and analytics. These machines might connect to the internet of things (IoT), providing insights into usage patterns, maintenance schedules, and even inventory management. This could lead to predictive maintenance, reducing downtime and ensuring a seamless sandwich-making experience.

Augmented Reality in Sandwich MakingAugmented reality (AR) might play a role in the future of sandwich making, especially in the realm of customization. Imagine walking up to a machine that uses AR to show you how different ingredients will look together, allowing you to visualize your sandwich before it’s made. This could be particularly appealing in high-traffic areas where speed and accuracy are key.

Health and Nutrition TrackingAs health consciousness grows, sandwich machines could be equipped with features that track nutritional information. They might be able to provide a detailed breakdown of the ingredients, calories, and dietary fiber, making it easier for consumers to make informed choices about their meals.

Personalized Recipes and MenusWith the help of machine learning algorithms, sandwich machines could offer personalized recipes based on user preferences and dietary restrictions. These algorithms could learn from past selections and suggest new combinations, introducing customers to new flavors and ingredients.

The Rise of Automated Delivery SystemsAs automation continues to advance, we might see sandwich machines that are not just in restaurants but also in delivery trucks or even as a part of home appliances. Imagine ordering your sandwich online and having it delivered to your doorstep, freshly made by an automated machine.

The Globalization of FlavorsThe future of sandwich making could also see a globalization of flavors. Machines might be able to replicate traditional sandwich styles from around the world, bringing the taste of exotic locations to the fingertips of consumers wherever they are.

Ethical Sourcing and TransparencyConsumers are increasingly interested in where their food comes from. The future of sandwich making could involve machines that not only prepare the sandwiches but also provide information on the origins of the ingredients, ensuring ethical sourcing and transparency.

Adaptability to Changing TrendsFinally, the future sandwich machines will likely be designed with adaptability in mind. They’ll be able to adjust to changing food trends and consumer demands quickly, ensuring that the sandwich-making experience stays fresh and relevant.

In conclusion, the future of sandwich making is a blend of technology, sustainability, personalization, and global culinary influences. It’s an exciting prospect that promises to revolutionize how we think about and enjoy sandwiches.