Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving world of kitchen appliances, there’s a subtle yet significant shift occurring. The once straightforward, utilitarian gadgets are now being reimagined with a blend of technology, innovation, and aesthetic appeal. This transformation is particularly evident in the realm of sandwich plates, where integrated metal stamping is not just a manufacturing technique but a cornerstone of modern design. As we delve into the intricacies of this process and its impact on the market, it becomes clear that the future of kitchen appliances is not just about functionality—it’s about redefining the culinary experience itself.

In recent years, the kitchen has transformed from a mere space for cooking to a hub of culinary innovation and design. One of the most notable trends in this evolution is the rise of sandwich plates in modern kitchens. These versatile and stylish kitchenware have not only become a staple in many households but have also redefined the way we think about meal preparation and presentation.

Once seen as a simple and somewhat utilitarian tool, sandwich plates have now become a centerpiece in kitchen aesthetics. They are no longer just for serving sandwiches; they have expanded their repertoire to include a variety of dishes, from hearty salads to delectable desserts. The popularity of these plates can be attributed to several factors that resonate with today’s home cooks and culinary enthusiasts.

Firstly, the convenience factor is undeniable. Sandwich plates are designed to be both functional and easy to use. Their wide, flat surfaces accommodate a variety of toppings, making them ideal for layering ingredients for a visually appealing and satisfying meal. Whether it’s a lunchtime sandwich, a gourmet salad, or a creative spread for a picnic, these plates offer a seamless solution for food presentation.

Secondly, the aesthetic appeal of sandwich plates has caught the eye of design-conscious consumers. With a plethora of shapes, sizes, and designs available, these plates can complement any kitchen decor, from rustic and farmhouse styles to modern and minimalist aesthetics. The use of high-quality materials, such as ceramic, glass, and now, innovative metal stamping, has elevated the status of sandwich plates from everyday utensils to collectible items.

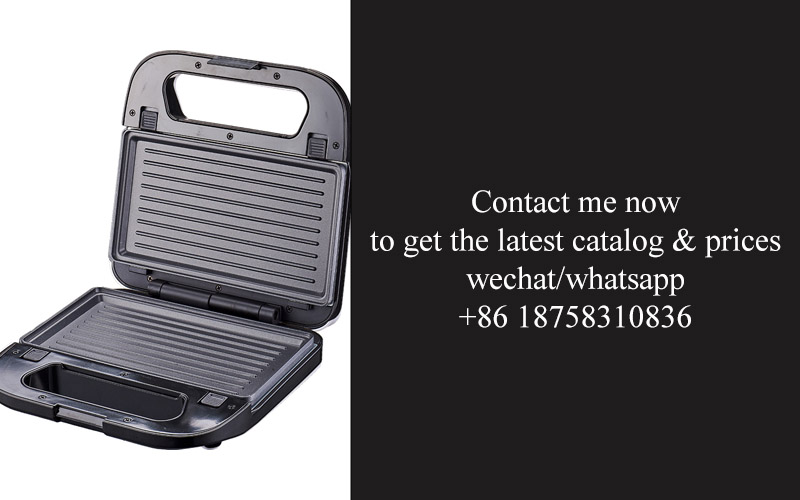

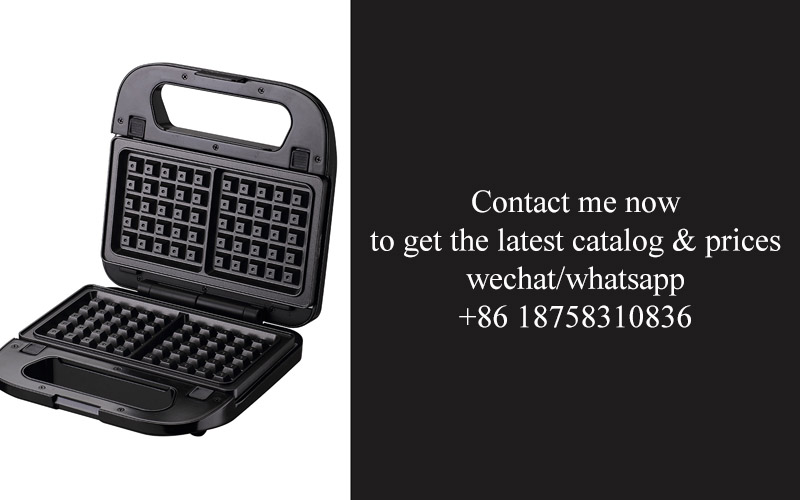

The advent of integrated metal stamping has been particularly transformative in the sandwich plate market. This advanced manufacturing technique allows for the creation of lightweight, durable, and visually striking plates. The ability to incorporate intricate patterns and seamless transitions between different materials has opened up new possibilities for designers, leading to a surge in unique and custom-made sandwich plates.

Moreover, the versatility of sandwich plates has expanded beyond the kitchen counter. They have become a popular choice for outdoor dining, thanks to their lightweight and easy-to-clean properties. Picnickers and tailgaters appreciate the portability and durability of these plates, which can withstand the rigors of outdoor settings.

The rise of sandwich plates is also a testament to the growing importance of food photography and social media in the culinary world. With platforms like Instagram and Pinterest, home cooks and food bloggers are constantly seeking new and creative ways to showcase their dishes. Sandwich plates offer the perfect canvas for these visual storytellers, allowing them to present their creations in a way that is both appetizing and Instagram-worthy.

Another factor contributing to the popularity of sandwich plates is the increasing emphasis on health and wellness. These plates often come with divided sections, which not only make portion control easier but also encourage mindful eating. The ability to separate ingredients can help in creating balanced meals that are rich in nutrients while being visually appealing.

Furthermore, the global culinary scene has influenced the demand for sandwich plates. As people travel more and are exposed to diverse cuisines, they often bring back inspiration that finds its way into their own kitchens. The international flavors that once required complex serving utensils can now be easily displayed on a simple, yet elegant sandwich plate.

In conclusion, the rise of sandwich plates in modern kitchens is a multifaceted phenomenon. It reflects the evolving needs of today’s consumers who seek convenience, style, and functionality in their kitchenware. As the technology behind these plates continues to advance, we can expect even more innovative designs and features that will further solidify their place as a must-have item in contemporary kitchens.

Integrated metal stamping has emerged as a pivotal technique in the design and production of sandwich plates, revolutionizing the way these kitchen essentials are crafted. This method, which involves shaping metal through the use of presses and dies, offers several distinct advantages that have significantly influenced the evolution of sandwich plate design.

The precision and consistency achieved through metal stamping are unmatched, allowing for intricate and uniform patterns that add a touch of sophistication to the most basic of sandwich plates. The process begins with high-quality metal sheets, which are carefully selected for their durability and ability to withstand the high temperatures and pressures of stamping. The result is a sandwich plate that not only performs well but also looks polished and modern.

One of the most notable aspects of integrated metal stamping is its ability to create intricate details and unique shapes. Designers can now experiment with various contours, edges, and textures, offering consumers a wide array of choices that cater to different tastes and kitchen aesthetics. The flexibility of metal stamping allows for the creation of sandwich plates with sleek, minimalist designs, as well as those with ornate patterns that echo traditional culinary styles.

Moreover, the uniformity of the metal stamping process ensures that every sandwich plate is of the highest quality, with consistent dimensions and finishes. This level of precision is crucial for the functionality of sandwich plates, as it guarantees a perfect fit for various cooking methods and cookware. Whether a sandwich plate is used for baking, grilling, or roasting, the seamless construction and reliable design provide a stable and even heat distribution, enhancing the cooking experience.

The strength and structural integrity of metal-stamped sandwich plates are also noteworthy. The metal material, often stainless steel or aluminum, is known for its resilience and resistance to warping and bending. This durability is particularly important for sandwich plates that are used frequently and may be subjected to heavy or uneven loads. The robust construction of these plates not only prolongs their lifespan but also ensures that they can withstand the rigors of professional kitchens as well as home cooking.

In addition to aesthetics and functionality, integrated metal stamping contributes to the sustainability of sandwich plate production. The process is highly efficient, requiring less material than traditional methods, which reduces waste. The metal sheets used in stamping can also be recycled, making this an environmentally friendly choice. This focus on sustainability aligns with the growing demand for eco-conscious products in the kitchen appliance market.

The design of sandwich plates has also been enhanced by the ability to incorporate innovative features through metal stamping. For instance, manufacturers can now integrate non-stick coatings directly into the metal surface during the stamping process. This not only streamlines production but also ensures that the non-stick properties are evenly distributed throughout the plate, making it easier to clean and maintain.

Furthermore, the use of metal stamping allows for the creation of sandwich plates with built-in features such as grooves or channels for better heat management and to prevent food from sticking. These design elements are not only practical but also add a unique visual appeal to the product.

Lastly, the versatility of integrated metal stamping extends to the customization of sandwich plates. Brands can now offer personalized designs, allowing customers to choose from a variety of colors, patterns, and finishes. This level of customization not only caters to the individual preferences of consumers but also opens up new marketing opportunities for manufacturers.

In conclusion, integrated metal stamping has become an indispensable tool in the design of sandwich plates. It has transformed the way these kitchen essentials are made, offering enhanced durability, aesthetics, functionality, and sustainability. As the demand for high-quality, innovative kitchenware continues to grow, the role of metal stamping in shaping the future of sandwich plate design is undeniable.

Integrated metal stamping has revolutionized the design and functionality of sandwich plates, offering a myriad of advantages that have become increasingly appealing to both manufacturers and consumers alike. Here’s a closer look at some of the key benefits:

The Strength and Durability of Metal StampingMetal stamping produces sandwich plates with exceptional strength and durability. The process involves forming metal sheets into precise shapes, which creates a robust structure that can withstand the rigors of everyday use. This means that plates made through metal stamping are less likely to warp, bend, or crack, ensuring a longer lifespan and reducing the frequency of replacements.

Enhanced Design FlexibilityOne of the standout advantages of integrated metal stamping is the design flexibility it offers. Unlike traditional manufacturing methods, metal stamping allows for intricate and complex shapes to be created with ease. This means that manufacturers can produce sandwich plates with unique features, such as built-in handles, non-slip bases, or innovative shapes that not only enhance usability but also add a touch of style to kitchen countertops.

Improved AestheticsThe sleek and modern look of sandwich plates crafted through metal stamping is a significant draw for consumers. The process can produce a smooth, uniform finish that is both visually appealing and easy to clean. The ability to create intricate patterns and designs on the surface of the plates also allows for a wide range of aesthetic possibilities, from minimalist to ornate, catering to different tastes and kitchen decors.

Cost-Effective ProductionMetal stamping is a highly efficient and cost-effective manufacturing process. It reduces the amount of material wasted during production and allows for high-volume production without compromising on quality. This efficiency translates into lower production costs, which can be passed on to consumers in the form of competitive pricing. Additionally, the longevity of metal-stamped sandwich plates means fewer replacements, further reducing overall costs over time.

Precision and ConsistencyThe precision of metal stamping ensures that each sandwich plate is produced to the same high standard. The process involves the use of dies and tools that are designed to create parts with tight tolerances, which means that every plate will fit together seamlessly. This consistency is crucial for products that are designed to be stackable or modular, as it ensures that the plates can be used in a variety of configurations without issues.

Corrosion ResistanceSandwich plates are often used in environments where moisture is present, whether it’s in the kitchen sink or on a picnic table. Metal stamping can be used to create sandwich plates with corrosion-resistant finishes, such as anodizing or powder coating. These finishes protect the metal from rust and extend the life of the product, making it an ideal choice for outdoor use or in humid conditions.

Ease of MaintenanceThe smooth surfaces of metal-stamped sandwich plates are not only aesthetically pleasing but also easy to maintain. The non-porous nature of the material means that food particles and dirt can be easily wiped away, reducing the need for harsh cleaning agents and minimizing the risk of stains. This ease of maintenance is a significant advantage for busy households and those looking for a low-maintenance kitchen accessory.

Customization and PersonalizationMetal stamping can be tailored to meet specific requirements, allowing for customization and personalization. Manufacturers can stamp logos, patterns, or even personalized messages onto the plates, making them a unique and special addition to any kitchen. This level of customization can be particularly appealing for businesses looking to brand their products or for consumers seeking a more personalized kitchen experience.

In conclusion, the advantages of integrated metal stamping for sandwich plates are clear. From enhanced strength and design flexibility to cost-effectiveness and corrosion resistance, this manufacturing process offers a comprehensive solution that addresses the needs of both manufacturers and consumers. As the demand for high-quality, durable, and aesthetically pleasing kitchenware continues to grow, it’s likely that the role of metal stamping in sandwich plate design will only become more prominent.

In the ever-evolving world of kitchen appliances, innovation is the driving force behind the latest trends and technologies. The art of innovation in kitchen appliances encompasses a blend of creativity, functionality, and practicality, all aimed at enhancing the cooking experience. Here are some key aspects that define this art:

The Fusion of Form and FunctionAppliances that seamlessly blend aesthetic appeal with utility are at the forefront of innovation. From sleek, minimalist designs to vibrant, colorful units, the fusion of form and function ensures that kitchen appliances not only perform their tasks efficiently but also add a touch of style to the space.

Smart IntegrationThe integration of smart technology into kitchen appliances is a game-changer. Smart ovens, refrigerators, and dishwashers, for example, offer users the ability to control and monitor their appliances remotely via smartphones or voice commands. This level of connectivity and convenience is reshaping how we interact with our kitchen tools.

User-Centric DesignInnovative appliance design often starts with the user in mind. User-centric designs consider how people use their appliances daily, focusing on ease of use, accessibility, and safety. Features like touchscreens, intuitive interfaces, and ergonomic handles are just a few examples of how appliances are tailored to the needs of their users.

Energy EfficiencyEnergy efficiency has become a cornerstone of innovation in kitchen appliances. Manufacturers are constantly seeking ways to reduce energy consumption while maintaining or improving performance. Energy-saving modes, LED lighting, and efficient heating elements are just a few ways appliances are becoming greener.

Sustainability InitiativesThe art of innovation in kitchen appliances also extends to sustainability. From using recycled materials in the construction of appliances to designing them for easy recycling at the end of their life, sustainability is a key consideration. Some appliances even come with features that help reduce waste, such as composting bins and water-saving systems.

Health and Wellness FeaturesAs awareness of health and wellness grows, so does the demand for appliances that support these lifestyles. Induction cooktops that reduce harmful emissions, air fryers that offer a healthier alternative to deep-frying, and refrigerators with built-in water filters are examples of how innovation is making kitchens healthier environments.

Customization and PersonalizationThe ability to customize and personalize kitchen appliances is another area where innovation thrives. Users can now choose from a variety of finishes, colors, and configurations to match their personal style. Some appliances even allow for upgrades, such as additional attachments or modules, to cater to specific cooking needs.

Interactive and Educational ToolsInnovation in kitchen appliances doesn’t stop at convenience and efficiency; it also extends to education and entertainment. Interactive cookbooks, recipe apps, and built-in educational tools help users learn new recipes and cooking techniques, making the kitchen a hub of learning and fun.

Integration with Smart HomesThe rise of smart homes has spurred innovation in kitchen appliances to work in harmony with other smart devices. From syncing with voice assistants to being controlled through home automation systems, kitchen appliances are becoming an integral part of a cohesive smart home ecosystem.

In summary, the art of innovation in kitchen appliances is a dynamic and multifaceted endeavor. It involves not just the creation of new technologies but also a deep understanding of consumer needs and desires. As technology continues to advance, we can expect even more innovative and exciting kitchen appliances to grace our homes, transforming the way we cook and live.

In the ever-evolving landscape of kitchen appliances, staying ahead of the curve is crucial. Let’s dive into the latest industry trends and conduct a market analysis that reveals the pulse of the sector.

The integration of smart technology continues to reshape the kitchen appliance industry. From smart ovens that can be controlled via a smartphone app to refrigerators that track your grocery list, innovation is pushing the boundaries of what’s possible.

Energy efficiency has become a significant trend, with manufacturers focusing on creating appliances that not only perform well but also conserve energy. This shift is not only environmentally friendly but also cost-effective for consumers looking to reduce their utility bills.

Sustainability is another key trend, with a growing number of consumers seeking appliances made from recycled materials or designed for easy recycling at the end of their lifespan. Brands that prioritize sustainability are gaining a competitive edge in the market.

Customization is on the rise, with appliances that can be tailored to individual preferences and kitchen layouts. Modular designs and customizable features allow homeowners to create a kitchen that is as unique as their lifestyle.

The market analysis shows a steady increase in demand for kitchen appliances that offer convenience. From hands-free faucets to induction cooktops that eliminate the need for pots and pans, convenience features are becoming more popular.

The integration of voice control and AI into kitchen appliances is also gaining traction. Consumers are embracing the idea of a kitchen that can be managed with simple voice commands, making cooking and cleaning tasks more efficient.

The market for kitchen appliances is becoming increasingly global, with consumers in developed countries leading the way in terms of adoption of new technologies. However, emerging markets are catching up rapidly, driven by a growing middle class and rising disposable incomes.

Brands that are successful in the current market are those that understand the importance of user experience. Appliances that are intuitive to use, aesthetically pleasing, and offer seamless integration with other smart home devices are more likely to succeed.

Innovation in materials is also a key trend. For example, the use of stainless steel for appliances is not only durable but also resistant to fingerprints and scratches, making it a preferred choice for many consumers.

The market analysis also indicates a shift towards healthier cooking options. Appliances that promote healthier cooking methods, such as air fryers and steam ovens, are gaining popularity as consumers become more health-conscious.

The rise of e-commerce has had a significant impact on the kitchen appliance market. Online sales platforms are providing consumers with a wider range of products and more competitive pricing, which is driving market growth.

Lastly, the market is witnessing a trend towards more integrated kitchen solutions. Appliances that work together to create a cohesive and efficient kitchen environment are becoming more sought after.

In conclusion, the kitchen appliance industry is in a state of flux, with new trends and technologies constantly emerging. Brands that can adapt to these changes and provide innovative, sustainable, and user-friendly products are poised to capture the market’s attention and grow their share.

In the ever-evolving landscape of kitchen appliances, the integration of smart technology has revolutionized the way we interact with our cooking tools. This transformation is particularly evident in the design of sandwich plates, where innovation meets functionality. Let’s delve into the profound impact of smart technology on sandwich plate design.

The advent of smart sensors has significantly enhanced the precision and efficiency of sandwich plates. These sensors can monitor temperature, pressure, and cooking time, ensuring that every sandwich is cooked to perfection. By providing real-time data, they allow users to make adjustments on the fly, leading to a more tailored and enjoyable cooking experience.

One of the most notable advancements is the incorporation of connectivity features. Modern sandwich plates are often equipped with Bluetooth or Wi-Fi capabilities, allowing them to sync with smartphones or tablets. This integration means users can control their appliances remotely, receive alerts about cooking progress, and even access a wealth of recipes and cooking tips directly from their devices.

Energy efficiency has become a cornerstone of smart kitchen appliance design, and sandwich plates are no exception. Smart technology enables these plates to optimize energy use, adjusting power levels based on the cooking requirements. This not only saves money on energy bills but also reduces the environmental footprint of our cooking habits.

Customization is another area where smart technology has made a substantial impact. With the ability to remember user preferences, sandwich plates can be programmed to deliver the perfect cooking experience every time. From preferred temperatures to preferred cooking modes, these appliances adapt to individual tastes, making them more than just a tool; they’re a personal assistant in the kitchen.

Safety features have also seen a major upgrade with the introduction of smart technology. Sensors can detect overcooking or uneven heating, automatically shutting off the appliance to prevent burns or fires. Additionally, some models include child safety locks and temperature limits, making them suitable for households with children.

In the realm of aesthetics, smart sandwich plates have embraced a sleek, modern look. The integration of touchscreens and intuitive interfaces has replaced traditional dials and buttons, giving these appliances a clean and sophisticated appearance. This design not only complements contemporary kitchen aesthetics but also makes them user-friendly for all ages.

Maintenance has become a breeze with smart technology. Some sandwich plates can be cleaned with a simple wipe-down, thanks to their non-stick surfaces and self-cleaning features. Others can even provide cleaning schedules and reminders, ensuring that the appliance stays in top condition.

The impact of smart technology in sandwich plate design extends beyond convenience and efficiency. It has opened up new possibilities for culinary exploration. Users can experiment with different cooking methods, such as sous-vide or air frying, directly from their sandwich plates, expanding their culinary horizons without the need for additional appliances.

From a commercial perspective, the integration of smart technology has also influenced marketing strategies. Manufacturers are now emphasizing connectivity and innovation as key selling points, attracting tech-savvy consumers who are eager to bring the latest advancements into their homes.

Looking ahead, the potential for further innovation in smart sandwich plate design is vast. We can expect to see even more sophisticated sensors, advanced connectivity options, and perhaps even the integration of voice control. As technology continues to advance, the line between kitchen appliances and smart devices will blur, leading to a future where cooking is not just a task but an interactive and enjoyable experience.

The impact of smart technology on sandwich plate design is a testament to the incredible pace of innovation in the kitchen appliance industry. It’s not just about making cooking easier; it’s about making it smarter, more personalized, and more enjoyable. As we move forward, the possibilities for what smart technology can bring to our kitchen appliances are as limitless as our culinary aspirations.

In the realm of kitchen appliances, there are several success stories that showcase the effectiveness and innovation of integrated metal stamping. Let’s delve into a few of these remarkable case studies.

The company “KitchenCraft Innovations” has made a name for itself by revolutionizing the design of sandwich plates through integrated metal stamping. Their process allowed for the creation of lightweight yet robust plates that are both durable and visually appealing.

Their success lies in the precision and efficiency of their metal stamping technique. By using advanced machinery, they are able to produce plates with intricate designs and seamless finishes. This not only enhances the aesthetic value of the product but also ensures that each plate is uniform in quality.

Another standout example is “SmartPlate Solutions,” a brand that has leveraged integrated metal stamping to integrate smart technology into their sandwich plates. Their innovative approach has allowed them to offer plates that not only serve as practical kitchenware but also provide valuable information to users.

The case study of SmartPlate Solutions reveals a meticulous process of design and testing. Their team of engineers and designers worked tirelessly to integrate features such as temperature control, food safety alerts, and even meal preparation guidance into the plates themselves. The result? A product that has become a game-changer in the kitchen appliance market.

The story of “EcoChef Appliances” is one of sustainability and innovation. By utilizing integrated metal stamping, they have developed sandwich plates that are not only eco-friendly but also offer superior performance. Their plates are made from recycled materials, and the stamping process ensures that no material is wasted during production.

EcoChef’s case study highlights the importance of considering the environmental impact of products. By using integrated metal stamping, they were able to create a product that is both sustainable and cost-effective. This has not only won them accolades in the industry but has also resonated with environmentally conscious consumers.

“UltraTech Kitchenware” is another company that has made significant strides in the field of integrated metal stamping. Their case study is particularly fascinating as it showcases how they have managed to combine functionality with style.

By using advanced metal stamping techniques, UltraTech has been able to produce sandwich plates that are not only strong and durable but also come in a variety of designs and finishes. Their plates are a hit among professional chefs and home cooks alike, who appreciate the balance between form and function.

One of the key factors contributing to UltraTech’s success is their commitment to quality control. They have stringent standards in place to ensure that every plate meets their high expectations. This dedication to excellence has helped them establish a strong brand reputation.

In the case of “HealthBake Appliances,” the focus was on creating sandwich plates that promote healthy eating habits. By integrating features such as portion control and nutritional information, they have managed to cater to the growing demand for health-conscious kitchenware.

The story of HealthBake Appliances demonstrates how integrated metal stamping can be used to address specific consumer needs. Their plates are designed to encourage users to make better food choices, and the metal stamping process has allowed them to incorporate these features seamlessly.

These case studies of success in integrated metal stamping for sandwich plates highlight the versatility and potential of this manufacturing technique. From enhancing aesthetics to integrating smart technology and promoting sustainability, the possibilities are vast. As the industry continues to evolve, we can expect to see more innovative applications of metal stamping in kitchen appliances, leading to a wealth of new opportunities for both manufacturers and consumers.

Metal stamping, a process that involves shaping metal by the application of pressure, has emerged as a pivotal technique in the design and manufacturing of sandwich plates. This method offers several advantages that have made it a favorite among appliance manufacturers and consumers alike. Let’s delve into the specifics.

Precision and CustomizationThe precision of metal stamping allows for intricate designs and detailed features that are often impossible to achieve with other manufacturing processes. This level of customization means that sandwich plates can be tailored to specific kitchen needs, whether it’s a sleek, modern look or a classic, vintage style.

Durability and StrengthMetal-stamped sandwich plates are renowned for their robustness. The pressure applied during the stamping process creates a strong bond between the layers of metal, resulting in a product that can withstand high temperatures and heavy usage. This durability ensures that the plates remain functional and aesthetically pleasing for years to come.

Corrosion ResistanceThe materials used in metal stamping, such as stainless steel, are highly resistant to corrosion. This is particularly important for sandwich plates that are often exposed to moisture and heat, as it prevents rust and extends the life of the product.

Weight and PortabilityThe lightweight nature of metal-stamped sandwich plates is a significant advantage. These plates are easier to handle and transport, making them a practical choice for those with limited storage space or who need to move them frequently.

Design FlexibilityMetal stamping opens up a world of design possibilities. From complex patterns to seamless transitions between different metals, the process allows for creative freedom that can result in unique and eye-catching kitchenware.

Cost-EffectivenessDespite the high precision and quality, metal stamping can be a cost-effective manufacturing process. The efficiency of the technique, combined with the ability to produce large quantities, can lead to economies of scale that benefit both manufacturers and consumers.

Environmental ConsiderationsMetal stamping is also environmentally friendly. The materials used are recyclable, and the process itself generates minimal waste. Additionally, the longevity of metal-stamped products reduces the need for frequent replacements, thereby minimizing the environmental impact over time.

Innovation in FunctionalityThe versatility of metal stamping extends beyond aesthetics. It allows for the integration of functional features such as non-slip bases, heat-resistant handles, and built-in indicators for temperature control. These innovations enhance the user experience and make metal-stamped sandwich plates not just visually appealing but also highly practical.

Market AcceptanceThe market has responded positively to the advantages of metal-stamped sandwich plates. Consumers are drawn to the durability, ease of maintenance, and the sleek, modern look that these plates offer. As a result, sales have been on the rise, with a growing number of households incorporating them into their kitchenware collections.

Technological AdvancementsThe evolution of metal stamping technology has also led to improvements in the quality and complexity of sandwich plates. Advanced machinery and techniques have allowed for thinner, lighter materials that still maintain structural integrity, further enhancing the appeal of these products.

In conclusion, the advantages of integrated metal stamping for sandwich plates are clear. The process offers a combination of durability, design flexibility, cost-effectiveness, and environmental benefits that have positioned it as a cornerstone in the kitchen appliance industry. As technology continues to advance, we can expect to see even more innovative and sustainable solutions emerging from the metal stamping world.

The evolution of integrated metal stamping has revolutionized the design and functionality of sandwich plates, offering a plethora of advantages that are reshaping the kitchen appliance industry. Let’s delve into how this process has transformed the landscape of sandwich plate design.

Precision and ConsistencyIntegrated metal stamping ensures a high level of precision and consistency in the production of sandwich plates. The use of molds and presses allows for the creation of uniform shapes and sizes, which is crucial for the structural integrity of the plates. This precision also translates to a more visually appealing product, as each plate maintains the same quality and finish.

Enhanced Strength and DurabilityOne of the most significant advantages of metal stamping in sandwich plate design is the increased strength and durability it provides. The metal material used in stamping, such as stainless steel, is known for its resilience and ability to withstand high temperatures. This means that sandwich plates made through this process are less likely to warp, crack, or bend over time, making them a reliable choice for heavy-duty use.

Lightweight and Sleek DesignContrary to the perception that metal is heavy, integrated metal stamping allows for the creation of lightweight sandwich plates. The process involves thin sheets of metal, which are stamped into shape, resulting in a product that is not only strong but also easy to handle. This lightweight design contributes to the overall aesthetic appeal of the plates, offering a sleek and modern look that complements contemporary kitchen interiors.

Customization and VersatilityMetal stamping offers a high degree of customization, allowing manufacturers to create sandwich plates with intricate designs and unique features. From embossed patterns to specialized shapes, the possibilities are endless. This versatility means that sandwich plates can be tailored to meet specific consumer needs and preferences, whether it’s for a commercial kitchen or a residential setting.

Efficient Production and Cost-EffectivenessThe integrated metal stamping process is highly efficient, capable of producing a large number of sandwich plates in a short amount of time. This efficiency translates to cost savings for manufacturers, as they can produce more units with fewer resources. Additionally, the streamlined production process reduces waste, further contributing to cost-effectiveness.

Easy Maintenance and CleaningSandwich plates designed with integrated metal stamping are not only durable but also easy to maintain. The smooth surfaces of these plates are resistant to stains and corrosion, making them a breeze to clean. This ease of maintenance is a significant factor for consumers who value time-saving and hassle-free kitchenware.

Environmental ConsiderationsIn recent years, environmental concerns have become a major driving force in the kitchen appliance industry. Integrated metal stamping offers an eco-friendly alternative to traditional manufacturing methods. The use of metal, which is highly recyclable, and the efficient production process contribute to a smaller carbon footprint. Moreover, the longevity of metal-stamped sandwich plates means they are less likely to end up in landfills.

As we look ahead, the future of integrated metal stamping in sandwich plate design appears promising. Here are some potential trends and advancements:

Smart IntegrationThe next wave of innovation may involve integrating smart technology into sandwich plates. Imagine a sandwich plate that can monitor temperature, cooking time, and even provide nutritional information. This integration would enhance the user experience and make cooking more efficient.

Advanced MaterialsThe development of new materials may further improve the performance of sandwich plates. Lightweight, high-strength metals or alloys could offer even greater durability and thermal resistance.

Customization on DemandWith advancements in 3D printing and customization technology, it’s possible that consumers could order sandwich plates with personalized designs or features, tailored to their specific needs.

Enhanced SustainabilityManufacturers will likely continue to focus on sustainability, exploring new ways to reduce waste and energy consumption in the production process. This could include the use of recycled metals and more energy-efficient stamping machinery.

In conclusion, integrated metal stamping has become a cornerstone in the design of sandwich plates, offering numerous benefits that cater to both the consumer and the environment. As technology evolves, we can expect to see even more innovative designs and features that will continue to shape the future of kitchen appliances.

In the ever-evolving landscape of kitchen appliances, the next generation is poised to redefine what it means to cook and live in the heart of our homes. The integration of advanced technologies and innovative designs has sparked a revolution that is not just about convenience but also about efficiency, sustainability, and personalization. As we stand on the brink of this new era, it’s clear that embracing the next generation of kitchen appliances is not just a choice but a necessity for those who wish to lead a more connected and efficient lifestyle.

The rise of smart kitchen appliances has transformed the way we interact with our cooking tools. Imagine a refrigerator that can not only keep your food fresh but also suggest recipes based on its contents, or an oven that can adjust its temperature and cooking time with precision. These advancements are not just about convenience; they’re about creating a seamless and intuitive cooking experience. The integration of artificial intelligence and machine learning into kitchen appliances is set to make cooking more personalized than ever before, catering to individual tastes and dietary preferences.

The design of these next-generation appliances is as forward-thinking as their functionality. Sleek, minimalist aesthetics are becoming the norm, with manufacturers focusing on creating kitchen spaces that are as visually appealing as they are functional. The use of high-quality materials and innovative construction techniques ensures that these appliances not only look great but also stand the test of time. The emphasis on ergonomics and user-friendliness means that even the most complex appliances can be used with ease, making cooking accessible to everyone, regardless of their skill level.

Sustainability is no longer an afterthought but a core principle guiding the development of kitchen appliances. As consumers become more environmentally conscious, manufacturers are responding by producing appliances that are energy-efficient, durable, and recyclable. The integration of renewable energy sources and smart energy management systems is not just reducing the carbon footprint but also lowering utility bills for homeowners. This shift towards sustainability is not just good for the planet; it’s also good for the wallet.

The market for kitchen appliances is undergoing a significant transformation, driven by changing consumer needs and technological advancements. There’s a growing trend towards multi-functional appliances that can perform multiple tasks, saving space and reducing clutter in the kitchen. Smart connectivity is another key trend, with appliances that can be controlled remotely via smartphones and other devices, allowing for greater flexibility and convenience. The market analysis shows a surge in demand for appliances that offer a balance between performance, design, and sustainability.

The impact of smart technology on sandwich plate design is profound. These plates are no longer just for serving; they are now integral to the cooking process. With features like built-in temperature controls and timers, they can ensure that your sandwiches are perfectly toasted and your fillings are heated to perfection. The ability to connect these plates to your kitchen’s smart system means you can start the cooking process before you even step into the kitchen, thanks to voice commands or a simple tap on your phone.

Case studies of companies that have successfully implemented integrated metal stamping in sandwich plate production highlight the benefits of this technology. For instance, one company has seen a significant reduction in production time and an increase in the durability of their sandwich plates. Another has managed to create a product that is both aesthetically pleasing and functionally superior, leading to increased customer satisfaction and market share.

In terms of sustainability, the use of metal stamping in sandwich plates is a game-changer. Metal is a highly recyclable material, and the precision of stamping ensures minimal waste during production. This not only reduces the environmental impact but also contributes to a more efficient supply chain. Companies that have embraced this approach are not only reducing their carbon footprint but also setting a precedent for others in the industry.

Looking ahead, the future of integrated metal stamping in sandwich plates is bright. As technology continues to advance, we can expect to see even more innovative designs and features. The integration of IoT (Internet of Things) capabilities could lead to sandwich plates that not only cook but also provide nutritional information and dietary recommendations. The potential for customization is vast, with users able to choose from a variety of materials, finishes, and functionalities to suit their specific needs.

In conclusion, the next generation of kitchen appliances is not just a glimpse into the future; it’s a reality that is rapidly becoming the norm. Embracing this new era means embracing a world where cooking is more efficient, sustainable, and enjoyable. As we move forward, it’s clear that the intersection of technology, design, and sustainability will continue to shape the kitchen appliances of tomorrow, offering us not just tools but experiences that enrich our daily lives.