Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving world of commercial kitchen equipment, the rise of the NSF approved sandwich press has sparked a whirlwind of excitement and curiosity. This game-changing innovation isn’t just a trend; it’s a testament to the industry’s relentless pursuit of quality, safety, and efficiency. Let’s delve into why this buzz around NSF commercial sandwich presses is more than just a fleeting fad—it’s a pivotal shift in the way we think about foodservice technology.

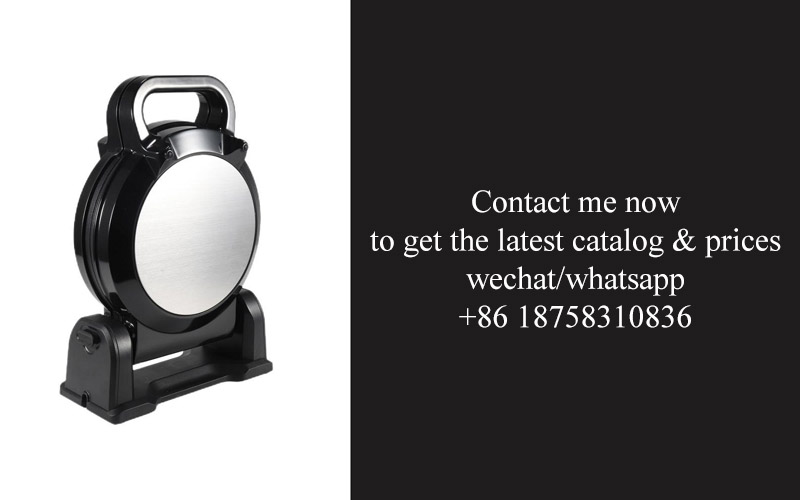

In recent years, the commercial sandwich press has seen a remarkable surge in popularity, transforming the way we think about fast food and casual dining. This simple yet revolutionary kitchen appliance has found its way into countless cafes, restaurants, and even food trucks, becoming an integral part of the modern culinary landscape.

The convenience and speed of these sandwich presses have made them a favorite among busy foodservice operators. They offer a quick and efficient way to cook a variety of sandwiches, from classic burgers to gourmet melts, with minimal effort and without the need for complex cooking skills. The rise of the commercial sandwich press can be attributed to several key factors.

Firstly, the demand for fast, yet satisfying meals has never been higher. With the hustle and bustle of modern life, consumers are looking for quick and convenient options that don’t compromise on taste. The sandwich press provides the perfect solution, allowing operators to serve up hot, freshly cooked sandwiches in a matter of minutes.

Secondly, the versatility of commercial sandwich presses is undeniable. They can handle a wide range of ingredients, from the traditional bun with lettuce, tomato, and cheese to more exotic combinations that cater to diverse palates. This adaptability has made them a favorite among establishments that want to offer a variety of menu items without the need for a multitude of cooking equipment.

Moreover, the rise of the commercial sandwich press has been fueled by the growth of the foodservice industry itself. As more restaurants and cafes open their doors, they’re seeking innovative ways to streamline their operations and increase efficiency. The sandwich press fits this need perfectly, as it can be easily integrated into existing workflows and doesn’t require a significant amount of space.

The advent of new technologies has also played a role in the sandwich press’s popularity. Modern presses are designed with features that make them more user-friendly and reliable. From non-stick surfaces that prevent food from sticking to the plates to adjustable heat settings that allow for precise cooking, these appliances are engineered to meet the demands of today’s kitchens.

Another factor contributing to the rise of commercial sandwich presses is the increasing awareness of food safety and quality. With the NSF (National Sanitation Foundation) approval, these presses have become a symbol of quality and reliability. The NSF certification ensures that the sandwich press meets stringent health and safety standards, giving operators peace of mind that their customers are consuming safe and hygienic food.

The portability of commercial sandwich presses is also a significant advantage. Operators can easily move these units from one location to another, whether they’re setting up a temporary food stand at an event or simply looking to change the layout of their kitchen. This flexibility makes the sandwich press a valuable asset for any foodservice business.

Furthermore, the commercial sandwich press has become a key player in the health and wellness trend. As more consumers seek out healthier eating options, the ability to customize sandwiches with fresh ingredients and minimal additives has become increasingly important. The press allows for a clean cooking method that preserves the natural flavors of the ingredients, making it an attractive choice for health-conscious diners.

The impact of social media and food blogging has also contributed to the sandwich press’s rise. With the ability to create visually appealing and appetizing sandwiches, these presses have become a favorite among chefs and food enthusiasts who share their creations online. The viral nature of social media has helped to spread the word about the sandwich press, turning it into a must-have item for any aspiring culinary entrepreneur.

In conclusion, the rise of the commercial sandwich press is a testament to the evolving foodservice industry and the changing preferences of consumers. As a convenient, versatile, and safe cooking tool, the sandwich press has earned its place as a staple in kitchens around the world. Its ability to adapt to new trends and technologies ensures that it will continue to be a popular choice for years to come.

In the bustling world of commercial kitchens, the significance of NSF approval for sandwich presses cannot be overstated. This stamp of approval from the National Sanitation Foundation has become a game-changer, reshaping the standards and expectations in the industry. Let’s delve into what exactly makes this certification so pivotal.

The NSF stands for the National Sanitation Foundation, an independent, not-for-profit organization that provides standards and certification for products that touch our daily lives. When a commercial sandwich press earns the NSF approval, it means it has met rigorous criteria for safety, health, and environmental management. This level of scrutiny is what sets it apart and elevates it to a new echelon.

One of the primary reasons NSF approval is a game-changer is its comprehensive nature. The certification process covers everything from material safety to the design of the sandwich press itself. This means that when a press is NSF-approved, it’s not just about the heat being evenly distributed across the bread, but also about the durability of the materials and the ease of cleaning. It’s a holistic approach that ensures the product is reliable and safe for use in professional settings.

The health and safety aspect is paramount in commercial kitchens, where even the smallest oversight can lead to significant consequences. NSF approval serves as a reassurance to both the users and the customers that the sandwich press is free from harmful substances, such as lead or BPA, and that it adheres to strict hygiene standards. This peace of mind is invaluable in an industry where reputation and public health are on the line.

Innovation is key in the culinary world, and the NSF approval process encourages manufacturers to push the boundaries of what’s possible with sandwich presses. By setting high standards, NSF motivates companies to develop products that not only perform well but also contribute to a more sustainable and environmentally friendly kitchen. This means energy-efficient designs, longer-lasting components, and an overall reduction in waste—a win for the environment and for businesses looking to reduce operational costs.

The impact of NSF approval extends beyond the product itself. It also influences purchasing decisions. When a commercial kitchen is considering which sandwich press to invest in, the NSF label is a major factor. It’s a trust signal that tells the kitchen manager or chef that they’re getting a quality product that meets industry standards. This can lead to better customer satisfaction, as the consistency and quality of the sandwiches are guaranteed.

Moreover, NSF approval can be a differentiator in a competitive market. For manufacturers, it’s an opportunity to stand out from the crowd and offer a product that is not just functional but also carries a level of credibility. This can translate into increased sales and a stronger market presence.

For the end-user, the benefits are clear. An NSF-approved sandwich press is less likely to malfunction or pose a health risk, which means fewer interruptions in service and a more efficient kitchen operation. This can lead to higher productivity and, ultimately, higher profits for the business.

The certification process is also a continuous improvement tool. Manufacturers are required to undergo regular audits to maintain their NSF approval, ensuring that the product remains up to date with the latest safety standards and innovations. This commitment to ongoing quality control is a testament to the reliability of the NSF certification.

In conclusion, the NSF approval for commercial sandwich presses is a game-changer because it represents a commitment to excellence in safety, health, and environmental responsibility. It provides peace of mind for users, enhances the reputation of the product, and encourages innovation in design and manufacturing. As the standards in the foodservice industry continue to evolve, the value of NSF approval will only grow, making it an indispensable credential for any sandwich press looking to make a mark in the commercial kitchen landscape.

In the ever-evolving world of commercial kitchen equipment, the sandwich press has emerged as a staple, and with it, a wave of innovations that have transformed the way we think about these compact appliances. When seeking an NSF approved sandwich press, there are several design features that stand out, each contributing to its effectiveness and reliability in a professional setting.

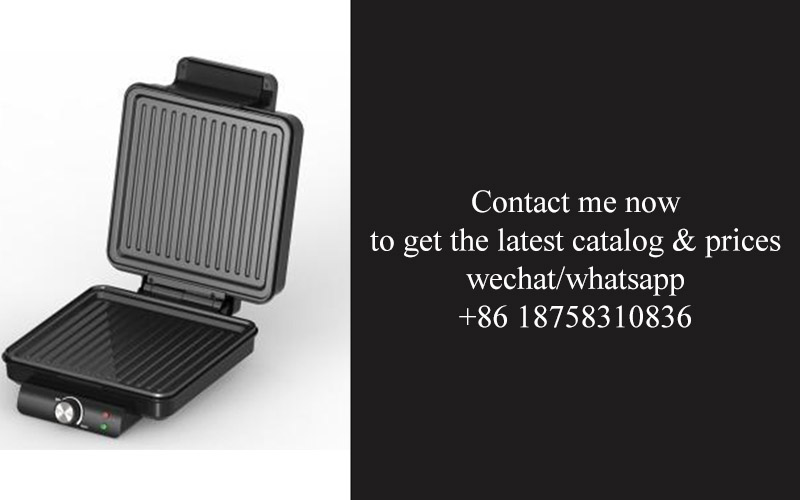

The first thing to consider is the heating element. Modern sandwich presses often come with precision-controlled heating elements that ensure consistent temperatures across the entire surface. This is crucial for maintaining the integrity of the ingredients, whether you’re crafting a classic grilled cheese or a gourmet panini.

Surface materials are also a key factor. Look for presses with non-stick surfaces that not only make clean-up a breeze but also prevent food from sticking, ensuring every sandwich is as perfect as the last. Some models even boast a ceramic-coated surface, which is not only non-stick but also boasts excellent heat distribution and durability.

Ease of use is another innovation that can’t be overlooked. Modern sandwich presses often come with features like adjustable pressure controls, allowing chefs to tailor the cooking process to their specific needs. This means you can achieve a perfectly toasted exterior while keeping the inside moist and tender.

Safety features are paramount in commercial kitchens, and an NSF approved sandwich press will likely include several. For instance, thermal cut-off switches prevent overheating, reducing the risk of fires and damage to the equipment. Additionally, cool-touch handles ensure operators can safely remove the sandwich press from the heat source without risk of burns.

The design of the press itself can greatly impact efficiency. Some models come with removable plates, making it easier to clean and maintain. Others feature a compact design that saves valuable counter space, a crucial consideration in busy commercial kitchens.

Innovation also extends to the build quality. Sandwich presses that are NSF approved are typically made from high-quality, heavy-duty materials that can withstand the rigors of a commercial kitchen environment. Look for presses with sturdy frames and durable hinges, as these will last longer and require less frequent maintenance.

Many modern sandwich presses are equipped with timers and temperature indicators. These features not only help chefs monitor the cooking process but also ensure that each sandwich is cooked to perfection every time. The ability to set specific cooking times and temperatures is a game-changer for consistency and efficiency.

The ability to customize the cooking experience is another area where design has made significant strides. Some presses offer adjustable plates that can accommodate different sizes of sandwiches, from small to extra-large. This versatility is particularly beneficial in environments where a variety of menu items are served.

Energy efficiency is also a growing concern in commercial kitchens. Sandwich presses that are designed to use less energy not only reduce utility bills but also contribute to a more sustainable operation. Features like energy-saving modes or eco-friendly materials are becoming more common in the latest models.

Lastly, consider the aesthetics of the sandwich press. While functionality is paramount, a sleek and modern design can enhance the overall look of your kitchen. Some presses come with a variety of finishes and colors, allowing you to choose a model that complements your kitchen’s decor.

In summary, the design of an NSF approved sandwich press has evolved to meet the demands of a professional kitchen. From precise heating elements and non-stick surfaces to safety features and energy efficiency, these innovations make for a more reliable, efficient, and user-friendly appliance. When selecting a sandwich press, it’s important to weigh these features carefully to ensure you’re investing in a piece of equipment that will serve your needs for years to come.

The surge in popularity of NSF-approved commercial sandwich presses is a testament to the evolving demands of the foodservice industry. These appliances have garnered a significant buzz for several compelling reasons:

In the heart of bustling restaurants and busy cafes, the demand for quick and high-quality sandwiches has never been higher. Customers are looking for convenience, and the right equipment can make all the difference. NSF approval is a seal of excellence that guarantees these sandwich presses meet stringent health and safety standards.

The rise of health-conscious consumers has also played a pivotal role. With an increasing focus on clean eating and nutritious options, sandwich presses offer a versatile platform to create custom, made-to-order meals. The buzz around NSF-approved models is due in part to their ability to deliver consistent, hygienic results every time.

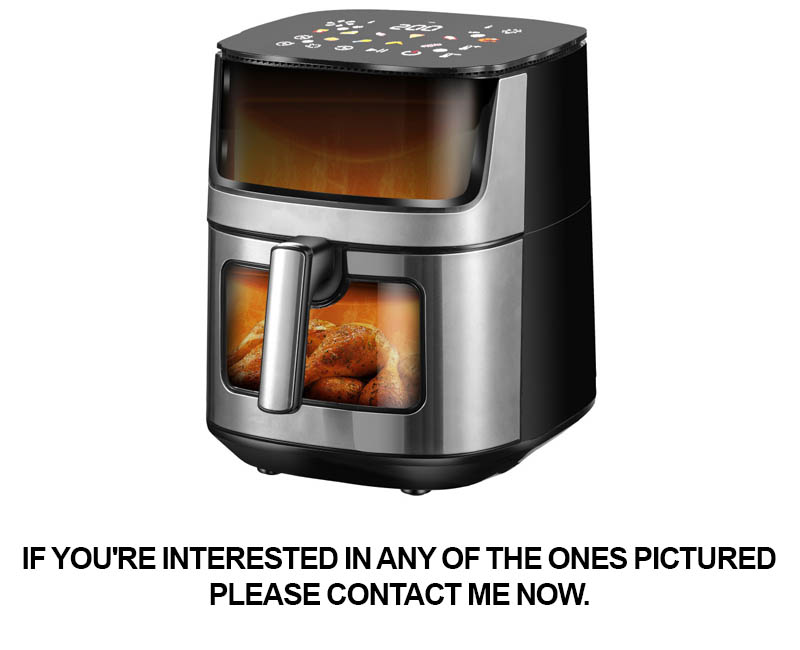

Modern kitchens are seeking efficiency, and these sandwich presses are designed with speed in mind. The technology behind them allows for rapid heating, ensuring that sandwiches are cooked to perfection in a fraction of the time compared to traditional methods. This efficiency is not just about reducing wait times; it’s also about maximizing kitchen productivity.

The integration of advanced features has further fueled the market’s interest. From non-stick surfaces that reduce the need for butter or oil to variable temperature controls that cater to different types of bread and fillings, these presses are equipped to handle a wide range of culinary needs. The buzz is a reflection of the industry’s excitement over these multifunctional tools.

Sustainability is another driving force behind the popularity of NSF commercial sandwich presses. With an emphasis on eco-friendly practices, these appliances are designed to be energy-efficient, reducing the carbon footprint of foodservice operations. The buzz is also a nod to the industry’s commitment to responsible stewardship of resources.

The trend towards personalized dining experiences has also contributed to the market’s dynamic. NSF-approved sandwich presses can be customized to fit various kitchen layouts and workflows. Whether it’s a sleek countertop model or a robust floor model, these presses are adaptable, making them a hot commodity in the competitive foodservice market.

The rise of social media and online reviews has not gone unnoticed. Chefs and kitchen managers are looking for the best tools to showcase their skills and attract customers. The NSF logo is a trust signal, and the buzz around these presses is often amplified by word-of-mouth and online recommendations.

Innovation in technology has also played a part. Features like Bluetooth connectivity for remote temperature control and data logging for quality assurance are becoming standard in many NSF-approved models. This tech-savviness is appealing to forward-thinking operators who want to stay ahead of the curve.

Lastly, the versatility of these sandwich presses cannot be overstated. They are not just for sandwiches; they can also be used for grilling wraps, heating subs, and even preparing small batches of paninis. The versatility, combined with the NSF stamp of approval, has created a perfect storm of interest in the commercial sandwich press market.

The market dynamics surrounding NSF commercial sandwich presses are a complex interplay of consumer preferences, technological advancements, and industry standards. The buzz is a clear indication that these appliances are not just a fleeting trend but a vital component of modern kitchen operations.

In the ever-evolving world of commercial kitchen equipment, the NSF (National Sanitation Foundation) approval has become a beacon of trust and quality. This standard isn’t just a label; it’s a promise of health and safety that resonates deeply within the market. The implications of NSF certification for commercial sandwich presses are profound, influencing everything from consumer confidence to operational efficiency.

The NSF standard is rigorous, ensuring that equipment meets strict criteria for material safety, structural integrity, and performance. For a sandwich press to earn this approval, it must undergo thorough testing for heat distribution, electrical safety, and cleanliness. This level of scrutiny means that when a commercial sandwich press carries the NSF mark, it’s not just a tool—it’s a safeguard.

Consumers, who are increasingly health-conscious, seek out products that adhere to high safety standards. An NSF-approved sandwich press can reassure diners that the food they’re enjoying is being prepared in a hygienic environment, using equipment that’s been vetted by a reputable third-party organization. This peace of mind can translate into loyalty for restaurants and cafes that prioritize safety.

From a regulatory standpoint, NSF certification is a powerful tool for compliance. For businesses operating in the foodservice industry, adhering to these standards isn’t just about avoiding fines or legal issues; it’s about upholding the integrity of the brand. The NSF logo on a sandwich press is a silent yet effective statement that the establishment takes its responsibility to serve safe food seriously.

Safety isn’t just about preventing accidents; it’s also about preventing the spread of foodborne illnesses. A sandwich press that maintains consistent temperatures and prevents cross-contamination is not just convenient—it’s essential. The NSF standard ensures that the equipment can handle the demands of a busy kitchen without compromising the health of the end consumer.

For manufacturers, achieving NSF approval is a testament to the quality of their products. It’s a competitive advantage in a market where differentiation is key. Customers who see the NSF mark are more likely to choose a brand over competitors, knowing that they are investing in a product that has passed stringent tests.

Moreover, the NSF standard encourages innovation within the industry. Manufacturers are pushed to create products that not only perform well but also meet the highest safety standards. This innovation isn’t just about new features; it’s about creating solutions that are not only efficient but also safe for use in a commercial setting.

From an environmental perspective, the implications of NSF certification are also significant. Equipment that meets NSF standards is often designed with sustainability in mind, using materials that are less harmful to the environment and more durable over time. This eco-friendly approach is becoming increasingly important to consumers and businesses alike.

The impact of NSF certification extends beyond the immediate product. It affects the entire supply chain, from the sourcing of materials to the manufacturing process and distribution. The standard requires that all components and processes are examined for safety and sustainability, ensuring that the sandwich press is not just a safe product but also one that aligns with broader environmental goals.

In the realm of insurance and liability, NSF approval can be a lifesaver for businesses. Insurance providers often offer preferential rates to establishments that use certified equipment, recognizing the reduced risk associated with compliance. This financial benefit can be a compelling reason for businesses to invest in NSF-approved sandwich presses.

In conclusion, the NSF standard and its implications for commercial sandwich presses are multifaceted. They range from enhancing consumer trust and regulatory compliance to driving innovation and sustainability. The NSF mark is more than a label; it’s a comprehensive assurance that the sandwich press is a reliable, safe, and responsible choice for any commercial kitchen.

In the bustling world of commercial kitchens, where time is money and quality is king, the adoption of NSF-approved sandwich presses has become more than just a trend—it’s a game-changer. These appliances aren’t just tools; they’re the backbone of efficiency and consistency in business operations. Let’s delve into how NSF approval not only boosts productivity but also ensures a seamless and high-quality workflow.

The precision of an NSF-approved sandwich press is unparalleled. These units are designed with a keen eye for detail, ensuring that every sandwich is cooked to perfection, every time. The even heat distribution guarantees that the bread is toasted just right, the fillings are heated to the perfect temperature, and the overall texture is mouthwatering. This level of precision not only enhances the customer experience but also streamlines the cooking process, allowing for faster service without compromising on quality.

Maintaining consistency is key in the food service industry, and NSF-approved sandwich presses play a crucial role in achieving this. These presses are engineered to deliver the same level of performance day in and day out. The consistent output means that your team can rely on these appliances to deliver the same delicious results, no matter the volume of orders. This reliability is especially important during peak hours when every minute counts, and every sandwich must be perfect.

Efficiency is another cornerstone of business success, and NSF-approved sandwich presses are designed to optimize the use of resources. These appliances are energy-efficient, consuming less power than their non-certified counterparts. This not only reduces operational costs but also aligns with the growing demand for sustainable practices in the foodservice industry. By using less energy, businesses can reduce their carbon footprint and contribute to a greener future.

In the realm of food safety, NSF-approved sandwich presses are a beacon of trust. The certification process involves rigorous inspections and testing to ensure that these appliances meet the highest standards for cleanliness and safety. This means that the equipment is designed to prevent cross-contamination, a major concern in commercial kitchens. With the peace of mind that comes from knowing your equipment adheres to strict health codes, restaurant owners and operators can focus on what they do best—serving great food.

The ease of use of NSF-approved sandwich presses also contributes significantly to efficiency. Modern designs often include intuitive controls and user-friendly interfaces that reduce training time for staff. Employees can quickly learn how to operate these presses, leading to less downtime and a more efficient workflow. Additionally, many NSF-approved models come with features like adjustable temperature settings and non-stick surfaces, which make cleaning a breeze and reduce the risk of food sticking, further enhancing efficiency.

Consistency in food quality is vital for customer satisfaction and repeat business. An NSF-approved sandwich press ensures that every sandwich is cooked to the same high standard, regardless of who is preparing it. This uniformity is achieved through consistent heat control, precise timing, and reliable performance. As a result, customers can expect the same level of quality whether they visit your establishment once or multiple times.

Moreover, the durability of NSF-approved sandwich presses cannot be overstated. These appliances are built to last, with high-quality materials and robust construction. This longevity means fewer repairs and replacements, which not only saves money but also minimizes disruption to your business operations. When your equipment is reliable, you can focus on other aspects of your business, such as customer service and menu development.

In conclusion, the NSF approval of commercial sandwich presses is not just a mark of quality—it’s a strategic advantage. The combination of precision, efficiency, consistency, and safety that these appliances bring to the table is invaluable in the fast-paced world of foodservice. By investing in NSF-approved sandwich presses, businesses can elevate their operations to new heights, ensuring that every sandwich served is not just delicious but also a testament to the commitment to excellence that customers expect.

In the bustling world of foodservice, the versatility of NSF approved sandwich presses has become a talking point across various dining establishments. These presses, once a staple in the fast-food sector, have now found their way into cafes, diners, and even upscale restaurants, proving their worth in more ways than one.

Cafeterias, known for their high volume and quick service, have embraced the convenience of sandwich presses. They allow for consistent, uniform sandwiches in a fraction of the time it would take to assemble them by hand. The even heat distribution ensures that every layer is toasted to perfection, a crucial factor for maintaining a fast-paced service environment. As a result, the lines move smoothly, and customers are satisfied with their quick, delicious meals.

Beyond the cafeteria setting, sandwich presses have become a favorite in diners, where the charm of a retro kitchen meets modern efficiency. These establishments often pride themselves on providing a homely atmosphere, and the warm, golden-brown sandwiches that come out of an NSF approved press are a nostalgic hit. The press not only gives a visual appeal to the sandwiches but also enhances their flavor, making them a centerpiece on the menu.

In the fine dining sector, where presentation is key, the versatility of these sandwich presses is undeniable. Chefs have started to use them to create unique, artisanal sandwiches that are as much a visual as they are a culinary delight. The ability to customize the toasting level and control the pressure ensures that each sandwich is crafted with precision. Whether it’s a delicate BLT or a hearty pastrami, the press becomes a tool for artistry, allowing chefs to offer their patrons a dining experience that goes beyond the typical.

The adaptability of NSF approved sandwich presses is also evident in their ability to cater to diverse dietary needs. With a simple adjustment in the press, operators can offer gluten-free, vegan, or keto-friendly options, broadening their customer base and appealing to a more health-conscious clientele. This flexibility is not just a bonus for diners; it’s a strategic move for businesses looking to stay competitive in an ever-evolving market.

The versatility of these sandwich presses also shines in their ease of use and maintenance. Their compact design and straightforward operation make them a practical choice for kitchens of all sizes. The ability to quickly switch between different sandwich sizes and styles without the need for specialized training is a significant advantage. This means that staff can focus on customer service rather than on the intricacies of sandwich preparation.

Moreover, the durability of these presses is a testament to their versatility. Made with high-quality materials and designed to withstand rigorous use, they are built to last. This durability is crucial for businesses that operate round the clock, ensuring that their sandwich presses are reliable even after years of continuous use.

The integration of advanced features in these sandwich presses has also contributed to their versatility. From adjustable heat settings to non-stick surfaces that reduce the need for oil, these innovations make the presses a more environmentally friendly option. The reduced cleanup time and energy consumption are additional benefits that align with the sustainability goals of many modern foodservice operations.

In conclusion, the rise of NSF approved sandwich presses in various dining environments highlights their remarkable versatility. From the fast-paced world of cafeterias to the refined atmosphere of fine dining establishments, these presses have proven to be a valuable asset. Their adaptability to different menus, dietary requirements, and operational needs makes them a staple in the kitchen, ensuring that the art of the sandwich is not just enjoyed but elevated across the spectrum of foodservice.

Investing in NSF certified commercial equipment is more than just a purchase; it’s a strategic move that can significantly impact the bottom line and reputation of a business. Let’s delve into the cost-benefit analysis of this investment.

The upfront cost of NSF certified equipment is often higher than that of standard models. However, this initial investment is often offset by the long-term savings and advantages these units offer. High-quality materials and rigorous testing ensure that NSF-certified equipment is built to last, reducing the frequency of repairs and replacements.

Energy efficiency is a key factor that often goes overlooked. NSF-certified commercial sandwich presses, for example, are designed with energy-saving features that can lead to substantial savings on utility bills over time. The efficient heating elements and insulation minimize energy consumption, which is not only good for the environment but also for your business’s profitability.

Maintaining consistency in product quality is crucial in the food service industry. NSF-certified equipment is tested to ensure it meets strict safety and performance standards, which means you can rely on it to deliver the same level of quality every time. Consistency in output can lead to higher customer satisfaction and repeat business, which, in turn, can significantly boost your revenue.

The health and safety of customers and employees are paramount. NSF certification is a mark of trust, assuring both that the equipment is safe to use and that it meets the highest hygiene standards. This peace of mind can be invaluable, especially in the wake of foodborne illness outbreaks that have caused reputational damage to countless establishments.

In the competitive food service market, compliance with health codes and regulations is not just a legal requirement; it’s a competitive edge. NSF certification can help differentiate your business from the competition by showcasing your commitment to quality and safety. This can attract more customers and potentially lead to premium pricing for your products.

The longevity of NSF-certified equipment means fewer disruptions to your business operations. Downtime due to equipment failure can be costly, both in terms of lost sales and the inconvenience to your customers. By investing in NSF-certified equipment, you’re investing in reliability, which can save you from these costly interruptions.

The initial cost of NSF-certified equipment may seem steep, but it’s important to consider the cost of training staff on new equipment. Standard models may require less training, but they may also have a shorter lifespan, leading to additional training costs over time. With NSF-certified equipment, the initial investment in training can pay off with years of consistent performance.

Another hidden cost of cheaper, non-certified equipment is the potential for higher maintenance costs. These units may require more frequent repairs and replacements, which can add up over time. NSF-certified equipment is designed to be durable and low-maintenance, reducing these ongoing expenses.

In the event of a recall or safety issue, having NSF-certified equipment can save your business from legal repercussions. Non-compliant equipment could lead to fines, lawsuits, or even the closure of your business. The certification serves as a safeguard against these risks, providing a layer of protection for your investment.

Lastly, consider the value of your brand. Investing in NSF-certified equipment can enhance your brand image, making it synonymous with quality and reliability. This can lead to increased customer loyalty and a stronger market position.

While the initial cost of NSF-certified commercial equipment may be higher, the long-term benefits, including reduced maintenance, increased efficiency, enhanced safety, and improved brand reputation, make it a wise investment. The cost-benefit analysis favors NSF-certified equipment, not just as a choice but as a necessity for any business aiming to thrive in the competitive food service industry.

In the ever-evolving landscape of commercial kitchen technology, the rise of NSF-approved sandwich presses has sparked a wave of innovation and efficiency. As these appliances gain popularity, it’s important to consider the future trends that are poised to shape the industry. From smart integration to eco-friendly designs, here’s a glimpse into what might be next for NSF-approved sandwich press technology.

The integration of smart technology is likely to become a cornerstone in the future of sandwich presses. Imagine a machine that not only cooks your sandwiches to perfection but also communicates with your kitchen management system. These smart presses could provide real-time data on usage, maintenance schedules, and even predictive maintenance, ensuring that your kitchen runs smoothly and efficiently.

Energy efficiency is another trend that’s set to make a significant impact. As sustainability becomes a more pressing concern for businesses, the next generation of NSF-approved sandwich presses may be designed with energy-saving features in mind. From programmable settings that reduce unnecessary energy use to eco-friendly materials, these presses could help reduce the carbon footprint of commercial kitchens.

Customization is key in the food service industry, and sandwich presses are no exception. The future may bring presses that offer a variety of pressing options, allowing chefs and kitchen staff to create unique sandwich experiences. Think of adjustable pressure settings, different heat levels, and even the ability to seal edges for a variety of fillings and bread types.

Ease of cleaning and maintenance will also be a focus. NSF certification already requires that equipment is easy to clean and sanitize, but the future could see presses that are even more user-friendly in this regard. Features like self-cleaning cycles, removable parts for easy cleaning, and materials that resist stains and odors could become standard.

Safety is paramount in commercial kitchens, and the future of sandwich press technology is likely to incorporate even more advanced safety features. This could include thermal sensors that prevent overheating, automatic shut-offs in case of power failures, and even smart alerts that notify staff of potential hazards.

The future of NSF-approved sandwich presses may also see a push towards modular designs. These presses could be built with interchangeable components, allowing for easy upgrades and modifications as technology advances. This modular approach would not only make it easier to adapt to new trends but also extend the lifespan of the equipment.

Innovation in materials is another area that could see significant developments. The next wave of sandwich presses might be made from advanced materials that are not only durable but also lightweight, reducing the overall weight of the equipment and potentially lowering shipping costs.

Lastly, the global nature of the food industry means that the future of sandwich press technology will also consider international standards and preferences. We could see presses that are designed to handle a wide range of bread types and fillings, catering to diverse culinary traditions around the world.

As the demand for high-quality, consistent sandwiches continues to grow, the future of NSF-approved sandwich press technology is sure to bring about exciting advancements. From smart integration to environmental sustainability, the next generation of these appliances promises to revolutionize the way we think about sandwich preparation in commercial kitchens.

Investing in NSF-certified commercial equipment isn’t just a choice; it’s a strategic move that can significantly impact the success and reputation of a commercial kitchen. From ensuring the highest standards of food safety to enhancing customer trust, the benefits are multifaceted. Here’s a closer look at the cost-benefit analysis of making the investment:

The upfront cost of NSF-certified equipment can be higher than standard models. However, this initial investment is often justified by the longevity and reliability of the equipment. NSF certification ensures that the product has undergone rigorous testing, which means it’s built to last and less likely to break down frequently, thus reducing the need for frequent repairs or replacements.

In the long run, the reduced maintenance costs can be substantial. Since NSF-approved equipment is designed to meet stringent safety and performance standards, they tend to operate more efficiently, which can lead to energy savings. Moreover, the durability of these products means fewer instances of unexpected downtime due to malfunctions, ensuring consistent service.

Consider the value of maintaining a clean and safe kitchen environment. NSF certification is synonymous with adherence to health codes and safety regulations. This not only protects your customers from foodborne illnesses but also avoids potential fines and legal issues that can arise from non-compliance. The peace of mind that comes with knowing your kitchen meets these high standards is invaluable.

In the world of food service, reputation is everything. By investing in NSF-certified equipment, you’re sending a clear message to your customers that food safety and quality are top priorities. This can differentiate your establishment from competitors and build loyalty among patrons who appreciate the extra effort to ensure a safe dining experience.

Labor costs are a significant factor in any business’s budget. NSF-certified equipment often features intuitive designs that reduce the complexity of operation. This can lead to increased efficiency in your kitchen staff, as they spend less time struggling with complex or inefficient machines. Time saved means more time to focus on customer service and food preparation quality.

The versatility of NSF-certified commercial equipment is another key benefit. Many NSF-approved products are designed to handle a wide range of tasks, which means they can replace multiple pieces of standard equipment. This consolidation not only saves space but also reduces the overall cost of ownership over time.

Think about the value of training. NSF certification often comes with a wealth of information on proper usage and maintenance. This can be a significant cost-saver for your business, as you’re likely to receive training and support from the manufacturer. Properly trained staff can lead to better performance and a longer lifespan for your equipment.

In the event that your NSF-certified equipment does require service or replacement, you can expect a higher level of support. NSF-approved manufacturers often offer warranties that reflect their commitment to the quality and safety of their products. This means that in the unlikely event of a problem, you have a safety net in place.

When evaluating the cost-benefit of NSF-certified commercial equipment, it’s important to consider the potential risks associated with non-certified alternatives. The financial and reputational damage that could result from a food safety incident or regulatory violation far outweighs the extra cost of NSF certification.

Lastly, investing in NSF-certified equipment is an investment in the future. As regulations continue to evolve and consumer expectations rise, having a kitchen that meets or exceeds these standards can position your business as a leader in food safety and quality.

In conclusion, while the initial cost of NSF-certified commercial equipment may be higher, the long-term savings, efficiency, safety, and reputation benefits make it a sound investment. It’s not just about the equipment itself; it’s about the entire package of peace of mind, customer trust, and business growth that comes with choosing equipment that has passed the stringent NSF certification process.