Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving culinary landscape, the industrial panini press has emerged as a versatile and efficient tool, bridging the gap between professional kitchens and home cooks. Its journey from sandwich shops to home kitchens is a testament to its adaptability and the growing demand for high-quality, quick-cooking appliances. As we delve into the world of industrial panini presses, it’s fascinating to explore the innovations that set them apart, the essential features to consider, and the profound impact they have on the food service industry. Moreover, the eco-friendly aspect of these presses adds a layer of sustainability to the cooking process. Through customer testimonials and a glimpse into the future, we can uncover the real-life experiences and the exciting developments that lie ahead in the world of industrial panini presses.

The industrial panini press has quietly been making waves in the culinary world, transforming the art of making sandwiches into a high-tech, efficient process. Once a staple in sandwich shops and cafes, these versatile appliances are now finding their way into home kitchens, redefining the way we think about at-home dining.

Once the domain of busy cafes and delis, the industrial panini press has seen a surge in popularity. It’s no longer just a tool for commercial kitchens; it’s now a sought-after gadget for food enthusiasts and home chefs alike. The sleek design and powerful performance of these presses have made them a must-have for anyone looking to elevate their sandwich game.

These presses are not just about convenience; they’re about quality. The even heat distribution and precise temperature control ensure that every sandwich is cooked to perfection, with a perfectly toasted crust and a juicy, tender interior. The rise of the industrial panini press is a testament to the growing trend of gourmet sandwiches that don’t compromise on taste or texture.

The technology behind these presses is nothing short of impressive. With advanced heating elements and adjustable temperature settings, chefs can tailor the cooking process to their specific needs. Whether you’re grilling a classic ham and cheese or experimenting with gourmet fillings, the industrial panini press offers the flexibility to create a wide array of mouthwatering sandwiches.

In the commercial kitchen, the industrial panini press has become an indispensable tool. It’s not just about the speed and efficiency it brings to the cooking process; it’s also about the consistency. Every sandwich that comes off the press is guaranteed to be evenly cooked, reducing waste and ensuring a high level of customer satisfaction.

The versatility of the industrial panini press is another reason for its popularity. These appliances can handle a variety of foods, from sandwiches to wraps, paninis, and even grilled cheese. The non-stick surfaces make it easy to clean and maintain, ensuring that the press stays in top condition for years to come.

The rise of the industrial panini press has also sparked a renewed interest in homemade sandwiches. With the convenience of these presses, home chefs can now enjoy the same level of quality and taste as they would find in a restaurant. It’s not just about the food; it’s about the experience. The process of making a sandwich on an industrial panini press can be a fun and rewarding activity, bringing family and friends together around the kitchen table.

Moreover, the industrial panini press has become a favorite among food bloggers and influencers. The visually appealing results and the ease of use have made these presses a go-to tool for creating stunning content. From step-by-step tutorials to mouth-watering before-and-after photos, the industrial panini press has become a symbol of culinary creativity.

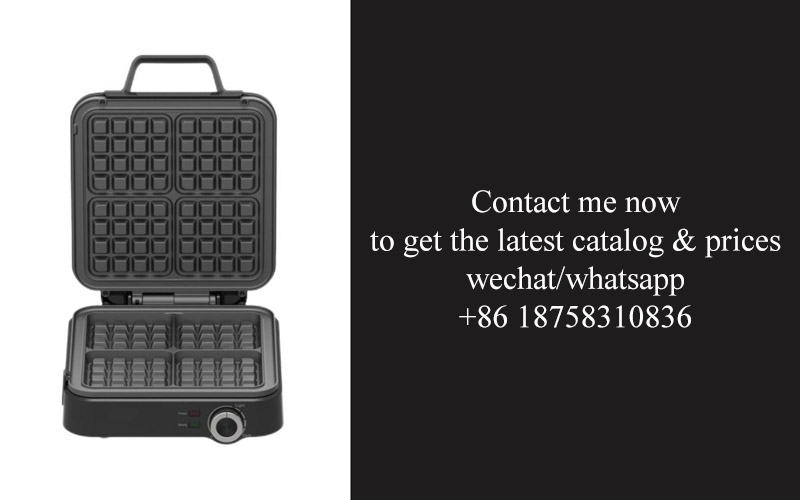

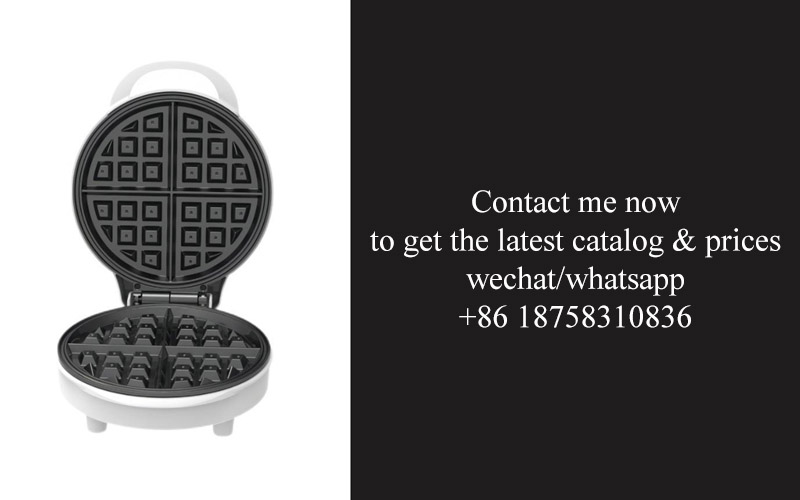

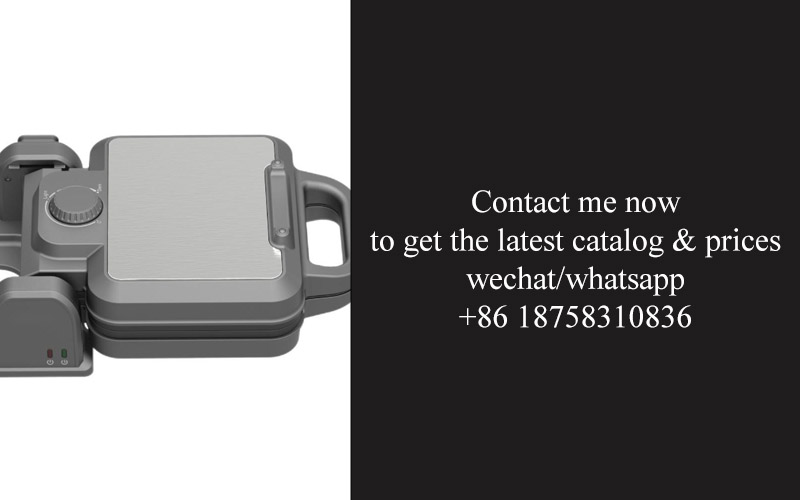

In terms of design, the industrial panini press has evolved to cater to both form and function. Modern models come with sleek finishes, often in brushed stainless steel or dark, elegant colors. The compact size makes them suitable for both small kitchens and busy countertops, without sacrificing cooking capacity.

The market for industrial panini presses has also seen a surge in innovation. New features such as adjustable pressure settings and programmable cooking times allow users to fine-tune their cooking experience. Some models even come with built-in timers and temperature indicators, making it easier than ever to achieve the perfect sandwich every time.

As the demand for high-quality, homemade meals continues to grow, the industrial panini press is poised to remain a staple in kitchens around the world. It’s not just a cooking tool; it’s a statement of culinary sophistication. Whether you’re a professional chef or a home cook looking to expand your culinary horizons, the industrial panini press is a game-changer that’s here to stay.

The humble panini press has come a long way since its inception, transforming from a staple in sandwich shops to a cherished appliance in home kitchens worldwide. Once a tool reserved for professional kitchens, the evolution of the panini press has been nothing short of remarkable.

In the early days, the panini press was a simple, flat device with two heating plates. It was introduced as a way to cook sandwiches with a delightful crunch and a touch of smokiness. These early models were often bulky and limited in functionality, but they were the precursor to the marvels we see today.

As the popularity of sandwiches surged, so too did the demand for more sophisticated panini presses. The once-plain devices began to boast features like adjustable temperature controls, non-stick surfaces, and even a flip-top design for easy access to the cooking surface. These innovations made the panini press not just a tool for cooking, but also a centerpiece for culinary creativity.

The rise of gourmet and health-conscious dining trends further propelled the evolution of the panini press. Consumers sought out appliances that could accommodate a variety of ingredients, from hearty fillings to delicate lettuce and cheese. As a result, the presses expanded to include features like adjustable pressure plates and a variety of heat settings to cater to different cooking styles and ingredients.

In the realm of sandwich shops, the panini press became a symbol of speed and efficiency. Fast-casual eateries relied on these appliances to serve a steady stream of customers with perfectly toasted sandwiches. The ability to cook multiple paninis at once meant that the presses could handle peak dining times without missing a beat.

But the transformation didn’t stop at the commercial sector. Home chefs began to see the potential of the panini press beyond the sandwich. Innovators started experimenting with the appliance to cook a wide array of foods, from pizzas to flatbreads to even desserts. The versatility of the panini press expanded, becoming a must-have for any aspiring home chef looking to add a bit of flair to their cooking.

The introduction of digital technology into the panini press also marked a significant shift. Digital temperature controls allowed for greater precision, ensuring that each panini was cooked to the perfect level of crispiness. The convenience of these digital models made them a favorite among busy parents and those who preferred a hands-off approach to cooking.

In recent years, the panini press has become even more integrated into the kitchen landscape. It’s not uncommon to find a sleek, countertop model in a modern kitchen, offering a touch of retro charm while providing practicality. The evolution of the panini press has also seen a surge in eco-friendly designs, with materials that are both durable and sustainable.

The panini press has also played a role in culinary competitions and food blogging. Chefs and enthusiasts alike showcase their skills by creating elaborate dishes using the panini press, pushing the boundaries of what was once considered a simple sandwich-making tool.

As the world continues to embrace global cuisine, the panini press has adapted to cook a variety of international dishes. From Italian paninis to Japanese yakitori to Middle Eastern falafel sandwiches, the versatility of the panini press has made it a universal kitchen companion.

Today, the panini press is not just a kitchen gadget; it’s a symbol of culinary adventure and innovation. Its journey from a simple sandwich shop tool to a versatile kitchen appliance has been a testament to the power of creativity and the changing tastes of consumers. Whether you’re a professional chef or a home cook, the panini press has found its place in kitchens around the globe, ready to toast up a world of flavors.

The industrial panini press has transcended its origins as a simple kitchen gadget to become a marvel of modern culinary innovation. What sets these robust machines apart from their domestic counterparts? Let’s delve into the features and technologies that make an industrial panini press truly stand out.

One of the most striking aspects of an industrial panini press is its build quality. These presses are designed to withstand the rigors of commercial use, often featuring heavy-duty stainless steel construction. This not only ensures durability but also contributes to the even distribution of heat, which is crucial for perfecting the golden-brown crust and melting the cheese in every sandwich.

The heating elements in an industrial panini press are typically more advanced than those found in residential models. They are designed to reach and maintain high temperatures quickly, which is essential for a high-volume kitchen environment. Some models even come with adjustable temperature controls, allowing chefs to tailor the cooking process to different types of bread and fillings, ensuring consistency and quality with every press.

Another innovation is the non-stick surface. While non-stick coatings are common in many kitchen appliances, the industrial grade ones are designed to withstand constant use and cleaning. This not only makes it easier to clean up spills but also reduces the need for oil or butter, leading to healthier sandwiches with less added fat.

The size and capacity of an industrial panini press are also noteworthy. These machines are often larger, capable of cooking multiple sandwiches at once, which is a game-changer for busy restaurants and delis. The wide surfaces and adjustable plates allow for a variety of sandwich sizes, from classic ham and cheese to gourmet creations with layers of fillings.

In terms of safety, industrial panini presses come with a range of features that prevent accidents. Overheating protection is standard, ensuring that the press will automatically shut off if it gets too hot. Additionally, many models include cool-touch handles and surfaces, reducing the risk of burns. Some even have locking mechanisms to prevent accidental opening while in use.

The design of an industrial panini press often includes features that make it easier to use in a commercial setting. For instance, the placement of the controls is strategic for easy access, and the plates are often designed to be easy to remove and clean. Some models also come with a drip tray to catch any excess moisture, keeping the workspace tidy and preventing messes.

Innovation also extends to the cooking process itself. Some industrial panini presses are equipped with steam injection systems, which add moisture to the cooking process, resulting in a softer, more tender texture inside the sandwich. This is particularly beneficial for breads with a higher moisture content, such as ciabatta or sourdough.

The technology in industrial panini presses doesn’t stop at the hardware. Many models are now equipped with digital displays that allow operators to monitor and adjust the cooking temperature and time. This not only ensures consistency but also allows for precise control over the cooking process, which is crucial for maintaining quality standards in a busy kitchen.

Lastly, the versatility of an industrial panini press is a testament to its innovation. While it’s primarily used for sandwiches, these versatile machines can also be used to cook wraps, flatbreads, and even small pizzas. This adaptability makes them a valuable addition to any kitchen that wants to offer a variety of quick-service options.

In conclusion, the industrial panini press stands out due to its robust construction, advanced heating technology, non-stick surfaces, large capacity, safety features, user-friendly design, and innovative cooking capabilities. It’s no wonder that these appliances have become a staple in the commercial kitchen, revolutionizing the way we think about sandwich preparation.

An industrial-grade panini press is not just a tool; it’s a workhorse in commercial kitchens. To ensure you’re getting the best out of your investment, here are the essential features you should look for in an industrial panini press.

Heavy-Duty Build: The foundation of any industrial panini press is its sturdy construction. Look for models made with commercial-grade stainless steel that can withstand the rigors of a busy kitchen environment. A solid build ensures durability and reliability, crucial for long-term use.

Large Cooking Surface: The cooking surface area is a key factor. Industrial presses often come with larger surfaces to handle multiple sandwiches at once, which is ideal for high-volume operations. A spacious surface means you can cater to a crowd without compromising on quality.

Consistent Heat Distribution: One of the hallmarks of a high-quality industrial panini press is even heat distribution. This feature prevents hot spots and ensures that each sandwich is cooked to perfection, every time. Look for presses with a heating element that covers the entire surface or a ceramic plate that promotes uniform cooking.

Adjustable Temperature Control: The ability to adjust the temperature is crucial for versatility. Different types of bread and fillings require different cooking temperatures. An industrial panini press with precise temperature control allows you to tailor the cooking process to the specific needs of your menu items.

Rapid Heat-Up Time: Time is money in a commercial kitchen. An industrial panini press that heats up quickly can get your operation rolling faster. Look for models that can reach optimal cooking temperature in a matter of minutes, rather than hours.

Non-Stick Coating: To maintain hygiene and ease of cleaning, a non-stick coating is a must. It prevents food from sticking to the surface, making it easier to remove and reducing the need for excessive scraping or scrubbing.

Easy-to-Clean Design: An industrial panini press is a workhorse, and that means it will get dirty. Look for models with a design that makes cleaning a breeze. Removable parts, a flat surface, and a non-stick coating all contribute to a more hygienic and efficient cleaning process.

Safety Features: Safety should always be a top priority. An industrial panini press should have features like a cool-to-the-touch exterior to prevent burns, a safety lock to prevent accidental operation, and an automatic shut-off function to minimize the risk of fires.

Portability and Space-Saving: While industrial presses are designed for heavy-duty use, they should still be practical in a commercial setting. Look for models that offer portability, such as those with casters or foldable legs, and those that are space-saving, with compact designs that won’t clutter your kitchen.

Warranty and Customer Support: A good warranty and reliable customer support can be a lifesaver. An industrial panini press is a significant investment, and knowing that the manufacturer stands behind their product can give you peace of mind. Check for a warranty that covers both parts and labor, and ensure that the manufacturer offers responsive customer service.

Additional Functions: Some industrial panini presses come with additional features like adjustable pressure, a reversible cooking plate for different styles of sandwiches, or even a built-in timer. These extra functions can enhance your cooking capabilities and make your kitchen more versatile.

Brand Reputation: Finally, consider the reputation of the brand. A well-known and trusted brand often means better quality control and customer satisfaction. Research reviews and ratings from other commercial kitchen professionals to get an idea of the brand’s reliability and customer service.

By focusing on these features, you can find an industrial panini press that not only meets your current needs but also has the potential to grow with your business. Whether you’re running a busy sandwich shop or a large-scale catering operation, investing in the right panini press can make all the difference in the quality of your sandwiches and the efficiency of your kitchen.

In the ever-evolving landscape of the kitchen appliances market, the industrial panini press has emerged as a significant player. Understanding the demand and growth trends of this niche product requires a closer look at consumer preferences, market dynamics, and technological advancements.

The surge in health-conscious eating habits has propelled the demand for fresh, homemade sandwiches. Consumers are seeking alternatives to processed foods, and the industrial panini press has become a symbol of convenience and quality. This shift in dietary preferences has directly influenced the growth of the industrial panini press market.

The rise of food trucks and pop-up restaurants has also contributed to the increased demand for industrial-grade appliances. These mobile kitchens require durable, efficient equipment that can withstand the rigors of frequent use and travel. The panini press, with its ability to quickly cook a variety of sandwich fillings, has become a staple in these dynamic dining environments.

Technology has played a pivotal role in shaping the growth trends of the industrial panini press market. The integration of features like non-stick surfaces, adjustable heat settings, and programmable cooking times has made these appliances more versatile and user-friendly. Additionally, advancements in materials and construction have led to more durable and reliable products.

One key trend is the demand for customizable options. Many businesses are looking for appliances that can cater to specific menu items or customer preferences. This has led to the development of panini presses with unique shapes and sizes, as well as those capable of cooking a range of foods beyond sandwiches, such as wraps, flatbreads, and even pizza.

The market for industrial panini presses is also influenced by regional factors. In areas with a strong emphasis on fast-casual dining, there is a higher demand for these appliances. Similarly, in regions where outdoor events and festivals are popular, portable and easy-to-use panini presses are in high demand.

Another important aspect to consider is the environmental impact of kitchen appliances. As sustainability becomes a more pressing issue, manufacturers are focusing on creating energy-efficient and eco-friendly panini presses. This not only appeals to environmentally conscious consumers but also helps businesses reduce their carbon footprint.

The demand for industrial panini presses has also been bolstered by the rise of online sales and e-commerce platforms. These channels have made it easier for businesses to source high-quality appliances without the need for physical store visits. This accessibility has expanded the market reach and contributed to the overall growth of the industry.

In terms of growth trends, the industrial panini press market is expected to see continued expansion in the coming years. The increasing popularity of street food and the demand for high-quality, fast-casual dining experiences are expected to drive demand. Additionally, the integration of smart technology and connectivity in these appliances could open up new opportunities for innovation and market growth.

The global nature of the market has also created opportunities for cross-border collaborations and partnerships. Manufacturers are looking to leverage the expertise of international suppliers to create products that appeal to a global audience. This internationalization of the market is likely to further fuel growth and innovation.

In conclusion, the demand for industrial panini presses is driven by a combination of health trends, technological advancements, and evolving consumer preferences. By understanding these factors, businesses can better position themselves within the market and capitalize on the growth trends that are shaping the industry.

In the world of culinary art, the industrial panini press has emerged as a versatile tool that can transform the way we cook. Here are some tips and tricks to master the art of cooking with an industrial panini press:

The Power of PressureOne of the standout features of an industrial panini press is the even distribution of pressure it provides. This pressure ensures that your sandwiches, wraps, or other flatbreads are cooked to perfection. Embrace the power of pressure by using the press to its fullest potential, pressing down firmly on the food to achieve a crispy, golden-brown exterior.

Perfecting the ToastWhile panini presses are often associated with sandwiches, they can also be used to toast bread to a delightful crunch. Load your favorite bread slices into the press, close it, and let the heat do its magic. The even heat distribution ensures that every slice is toasted uniformly, making for a perfect base for your breakfast or snack.

Mastering the FlipCooking with an industrial panini press requires a bit of timing and technique. Once you’ve loaded your ingredients, you’ll need to flip the press to cook both sides. The key is to do this at the right moment. Watch for the first signs of browning on one side, then carefully open the press, flip the food over, and close it again. This ensures that both sides cook evenly and prevents burning.

Experiment with IngredientsThe beauty of the industrial panini press lies in its ability to cook a variety of ingredients. Don’t be afraid to experiment with different meats, cheeses, vegetables, and spreads. Layering ingredients creatively can result in mouthwatering combinations that will impress even the most discerning palates.

Keep It CleanAfter each use, it’s crucial to clean your industrial panini press thoroughly. Food particles can burn and leave residue, which can affect the taste and performance of your press. Use a non-abrasive sponge or cloth to wipe down the surfaces, and make sure to remove any leftover food from the non-stick surfaces. Regular cleaning not only prolongs the life of your press but also ensures that each meal is as fresh as the last.

Preheat to PerfectionTo achieve the best results, always preheat your industrial panini press before cooking. The even heat helps to seal in the flavors and ensures that your food cooks evenly. Most presses have a preheat indicator light, so use it as a guide. Once the light turns off or the press is hot to the touch, it’s ready for action.

Use the Right TemperatureIndustrial panini presses often come with adjustable temperature settings. Experiment with these settings to find the perfect temperature for your specific ingredients. For example, a higher temperature might be ideal for thick sandwiches or those with a lot of cheese, while a lower temperature can be better for delicate ingredients or lighter sandwiches.

Don’t OverloadWhile industrial panini presses are built to handle a good amount of weight, it’s important not to overload them. Overloading can lead to uneven cooking and may even damage the press. Stick to the recommended weight limits and you’ll be able to enjoy perfectly cooked meals every time.

Utilize the SidesMany industrial panini presses have sides that can be used for additional cooking tasks. These sides can be perfect for grilling vegetables, cooking sausages, or even making mini pizzas. Don’t hesitate to use these versatile features to expand your culinary repertoire.

Practice Makes PerfectLike any skill, mastering the art of cooking with an industrial panini press takes practice. Don’t get discouraged if your first few attempts aren’t perfect. Keep experimenting with different ingredients and techniques, and soon you’ll be able to create a variety of delicious dishes with ease.

Remember, the industrial panini press is more than just a sandwich maker; it’s a tool that can elevate your cooking to new heights. With the right ingredients, a bit of patience, and these tips and tricks, you’ll be able to create mouthwatering meals that will impress friends and family alike.

In the bustling world of food service, the introduction of the industrial panini press has sparked a revolution in efficiency and profitability. These robust appliances have not only transformed the way sandwiches are made but have also become a cornerstone in the quest for high-quality, quick-service meals. Here’s a closer look at the profound impact these presses have had on the industry:

The Speed FactorThe industrial panini press is a game-changer when it comes to speed. Unlike traditional grills or toasters, these machines can cook a sandwich in mere seconds. This rapid cooking time reduces wait times for customers, leading to increased turnover and happier patrons. The ability to serve sandwiches quickly is crucial in high-volume environments, where time is of the essence.

Consistency in QualityOne of the hallmarks of the industrial panini press is its ability to deliver consistent results. Whether it’s the perfect sear on the outer layers or the melting of cheese to the right texture, these presses ensure that every sandwich meets the same high standard. Consistency is key in maintaining customer satisfaction and brand reputation.

Reduced Labor CostsWith the industrial panini press’s ability to cook multiple sandwiches simultaneously, the need for multiple staff members to handle cooking tasks is diminished. This not only cuts down on labor costs but also allows staff to focus on other important aspects of service, such as customer interaction and cleaning.

Space OptimizationCompared to larger kitchen equipment, the industrial panini press takes up minimal counter space. This is a significant advantage in busy kitchens where every inch of space counts. The compact design allows for a more streamlined kitchen layout, making it easier to manage and maintain.

Increased Menu VarietyThe versatility of the industrial panini press has expanded the menu options for many food service establishments. From classic ham and cheese to gourmet creations with fresh ingredients, these presses can handle a wide range of fillings. This flexibility allows restaurants to cater to diverse tastes and offer a broader selection of items, potentially increasing sales.

Health and HygieneThe high heat generated by industrial panini presses helps to kill bacteria and other pathogens, contributing to better food safety standards. Additionally, the non-stick surfaces of many modern presses make cleaning a breeze, further enhancing hygiene in the kitchen.

Enhanced Customer ExperienceThe allure of freshly cooked, hot sandwiches is undeniable. The industrial panini press’s ability to produce a hot, crispy sandwich in a short amount of time adds to the overall dining experience. Customers appreciate the quick service and the deliciousness of the food, which can lead to repeat visits and positive word-of-mouth referrals.

Profit MarginsThe efficiency gains from using an industrial panini press often translate into higher profit margins. With quicker service, reduced labor costs, and the potential for a wider menu, food service operators can see a significant boost in their bottom line. The ability to offer a premium product at a reasonable price is a powerful strategy in the competitive food industry.

The Shift Towards ConvenienceIn today’s fast-paced world, convenience is king. The industrial panini press plays into this trend by providing a quick and convenient way to enjoy a meal. This aligns with the demand for on-the-go dining and can be a significant draw for busy professionals and students.

Innovation in Cooking TechniquesThe use of industrial panini presses has also spurred innovation in cooking techniques. Chefs and kitchen staff are experimenting with different types of bread, fillings, and cooking temperatures to create unique and appealing dishes. This innovation can help establishments differentiate themselves in a crowded market.

The environmental ImpactLastly, the industrial panini press contributes to a more sustainable kitchen environment. By reducing energy consumption through efficient cooking and minimizing waste, these presses are part of a broader effort to operate more eco-friendly kitchens. This can appeal to environmentally conscious consumers and help businesses to promote their green credentials.

In summary, the industrial panini press has had a multifaceted impact on the food service industry. From enhancing efficiency and profitability to offering a superior customer experience, these presses are a valuable asset for any establishment looking to stay ahead in the competitive landscape of quick-service dining.

Industrial panini presses have not only revolutionized the way we cook sandwiches but have also paved the way for a greener and more sustainable approach to food service. Here’s a closer look at how these appliances are making a positive impact on the environment.

The Shift Towards Energy EfficiencyModern industrial panini presses are designed with energy efficiency in mind. With advancements in technology, these machines now use less power to achieve the same level of heat distribution and cooking performance. This reduction in energy consumption is a significant step towards a more sustainable future, as it lessens the carbon footprint associated with electricity production.

Heat Retention and ConsistencyOne of the key features of industrial panini presses is their ability to retain heat effectively. This not only ensures that sandwiches are cooked to perfection every time but also reduces the need for continuous heating. By maintaining a consistent temperature, these presses minimize energy waste, further contributing to their eco-friendly nature.

Sustainable MaterialsMany industrial panini presses are now made from sustainable materials, such as stainless steel and recycled plastics. These materials are not only durable but also have a lower environmental impact compared to traditional materials. The use of these materials in the manufacturing process reduces the need for raw materials and contributes to a circular economy.

Reduced Waste in ProductionThe design of industrial panini presses has evolved to minimize waste during production. By streamlining the manufacturing process and using precise cutting techniques, manufacturers can produce presses that are not only functional but also efficient in terms of material usage. This reduction in waste helps to conserve resources and reduce the environmental impact of the production cycle.

Energy-Saving FeaturesIndustrial panini presses often come with features that help save energy. For instance, some models have an automatic shut-off function that turns off the press after a certain period of inactivity. This not only prevents unnecessary energy use but also extends the life of the appliance by reducing wear and tear.

Water-Saving Cooking MethodsWhile industrial panini presses are primarily used for cooking sandwiches, they also promote water-saving cooking methods. By using heat to cook food rather than boiling or steaming, these presses reduce the amount of water needed. This is particularly beneficial in commercial kitchens where large quantities of food are prepared daily.

Reduced PackagingThe packaging of industrial panini presses has also become more environmentally conscious. Many manufacturers are now using biodegradable or recyclable materials for packaging, which helps to minimize the environmental impact of shipping and distribution.

Community and Corporate ResponsibilityThe adoption of eco-friendly practices in the production and use of industrial panini presses is not just a trend; it’s a reflection of corporate responsibility. Many companies are taking steps to ensure that their products are produced in an environmentally sustainable manner, and they are also encouraging their customers to do the same.

Consumer Awareness and DemandAs consumers become more aware of the environmental impact of their choices, there is a growing demand for eco-friendly products. Industrial panini presses that are designed with sustainability in mind are not only appealing to environmentally conscious consumers but also to businesses looking to reduce their carbon footprint.

Innovation in DesignThe design of industrial panini presses continues to evolve, with new models incorporating features that are not only efficient but also sustainable. From the materials used to the cooking techniques, these appliances are becoming more integrated into a broader movement towards green living.

In conclusion, the green side of industrial panini presses is a multifaceted approach that touches on every aspect of their lifecycle, from production to usage and disposal. By focusing on energy efficiency, sustainable materials, and innovative design, these appliances are making a significant impact on the environment, encouraging a more sustainable food service industry.

After a long day, nothing beats the satisfaction of a perfectly toasted panini, and industrial panini presses have become the unsung heroes of food service. Here’s a glimpse into the real-life experiences of those who’ve embraced this modern cooking marvel.

The First Time: A Revolution in ToastingThe transition from conventional grills to industrial panini presses was a game-changer for Joe, a sandwich shop owner. “I remember the first time I used it,” he recalls. “The even heat distribution, the ability to lock in flavors—there was a noticeable difference right away.”

Flawless Consistency: A Key to SuccessConsistency is crucial in the food industry, and for Sarah, a café manager, her industrial panini press has been a godsend. “It’s like every sandwich comes out of the machine tasting just like the last one,” she notes. “Our customers love that reliability.”

The Power of VersatilityFor John, a caterer, the versatility of the industrial panini press has been invaluable. “From pressed sandwiches to grilled cheeses, it’s been a hit at every event. I can even cook open-faced sandwiches for those who prefer them that way.”

No More Burnt FingersBefore investing in the press, Emily, a home chef, used to dread making sandwiches due to the risk of burning her fingers. “Now, I can cook to perfection without even touching the sandwich,” she says. “It’s safe, easy, and the results are fantastic.”

Quality Over Quantity“The quality of the panini is unmatched,” claims Mark, who runs a bustling restaurant. “Even when we’re cooking for a hundred, the press doesn’t miss a beat. It’s all about speed and quality, and this machine delivers both.”

The Feedback Loop: Customer SatisfactionCustomer feedback has been overwhelmingly positive, according to Lisa, who operates a food truck. “Our customers are constantly complimenting the taste and texture of the sandwiches. It’s clear that the industrial panini press has significantly raised the bar for our menu.”

From the Inside: Staff AppreciationThe staff also benefits from the switch, says David, a chef at a diner. “The ease of use has cut down on prep time and made the kitchen a more pleasant place to work. Our team is much happier with the press than with the old grills.”

Maintenance is KeyMaintenance has been a breeze for Tom, who runs a small café. “It’s simple to clean and maintain, which means it’s ready for action whenever we need it. We’ve never had any issues with performance or durability.”

The Long-Term InvestmentFor many, the industrial panini press is more than just a tool; it’s a long-term investment. “It’s been a couple of years now, and it’s still going strong,” says Sarah. “I’m glad we made the switch—it’s paid for itself many times over.”

In conclusion, the industrial panini press has become a staple in the food service industry, and its real-life experiences highlight its transformative impact on everything from restaurant kitchens to home dining tables. From enhanced safety and efficiency to increased customer satisfaction, the press has earned its place as a kitchen essential.

In the ever-evolving world of kitchen appliances, industrial panini presses have quietly become a staple in both commercial kitchens and home cooking enthusiasts’ arsenals. As we look ahead, the future of these versatile machines is shaping up to be as innovative as it is sustainable. From smart technology integration to eco-friendly designs, here’s what we can anticipate in the next wave of industrial panini presses.

The integration of smart technology is a trend that’s not just catching on but is expected to become the norm. Imagine a panini press that not only cooks your sandwiches to perfection but also learns your preferences over time. These futuristic presses could come equipped with touchscreens that allow for easy customization of settings, from temperature control to cooking time. With the rise of the Internet of Things (IoT), these machines might even be able to sync with your smartphone, providing real-time updates and alerts.

Sustainability is another area where we can expect significant advancements. As awareness of environmental issues grows, manufacturers are increasingly focusing on the lifecycle of their products. This means we might see industrial panini presses made from recycled materials, designed with energy efficiency in mind, and equipped with features that reduce waste. For instance, a press with a self-cleaning function could save on water and cleaning agents, contributing to a greener kitchen environment.

The design of industrial panini presses is also likely to evolve. Smaller, countertop models could become more popular for cafes and small restaurants, offering a space-saving solution without compromising on cooking power. Conversely, larger models might incorporate modular components, allowing for easy upgrades and customization to meet specific business needs.

Safety features are another area ripe for innovation. With the potential for high temperatures and fast cooking, ensuring user safety is paramount. We could see presses with advanced heat sensors that prevent overheating and protect against accidental burns. Additionally, ergonomic handles and non-slip bases could make the cooking process safer and more comfortable for chefs and kitchen staff.

The culinary world is constantly seeking new and exciting flavors, and industrial panini presses might play a role in this quest. Imagine a press that can not only cook your classic sandwiches but also sear vegetables or grill proteins to add a unique texture and taste. This could open up new possibilities for chefs to create innovative dishes that blend the best of grilling and sandwich-making.

The future of industrial panini presses may also include a focus on health and wellness. As consumers become more health-conscious, there’s a growing demand for appliances that can help prepare nutritious meals quickly and easily. A press with adjustable cooking temperatures could cater to those looking to achieve a perfect sear without the need for excessive oil, promoting healthier cooking habits.

Customization is another trend that’s likely to continue. Some presses might offer interchangeable plates, allowing for different cooking styles, from crispy to tender. This versatility could be particularly appealing to establishments that cater to diverse dietary preferences and restrictions.

Finally, we should expect to see a surge in the use of AI and machine learning. These technologies could enable panini presses to optimize cooking times and temperatures based on the type of food being prepared, ensuring consistency and quality in every batch.

In conclusion, the future of industrial panini presses is bright with possibilities. From smart technology and sustainability to innovative designs and health-conscious features, these machines are poised to become even more integral to the food service industry and the homes of food enthusiasts. As we move forward, the evolution of the industrial panini press promises to be as dynamic and exciting as the food it serves.