Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Navigating the bustling world of foodservice and catering, one often encounters the humble yet indispensable sandwich—a versatile meal that’s as diverse as the cultures it spans. At the heart of this convenience lies the sandwich machine, a marvel of modern technology that has transformed the way we prepare these beloved snacks. As the demand for these machines continues to soar across various industries, it’s essential to delve into the factors that make a sandwich machine manufacturer truly stand out. From quality to innovation, and from industry-specific needs to the success stories that define their excellence, this exploration will shed light on the path to selecting the right sandwich machine manufacturer for your business.

Sandwich machines have become an integral part of the foodservice industry, streamlining the process of creating delicious and efficient meals. The manufacturing of these versatile appliances is a specialized field that requires precision engineering and innovative design. In this article, we delve into the fascinating world of sandwich machine manufacturing, exploring the intricacies involved and the key players shaping this niche market.

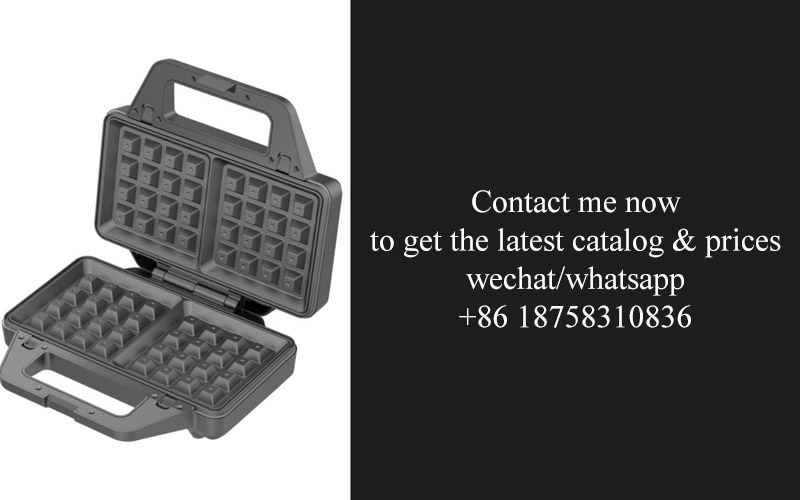

The journey begins with the concept, where designers and engineers brainstorm ideas to improve the functionality and user experience of sandwich machines. These machines come in various shapes and sizes, each tailored to specific needs, whether it’s for a bustling café, a busy fast-food chain, or a high-end restaurant.

The design phase is crucial, as it dictates the machine’s capabilities and ease of use. Engineers must consider factors such as heat distribution, speed, and the ability to handle different types of bread and fillings. Prototypes are then created, allowing manufacturers to test and refine their designs before moving to mass production.

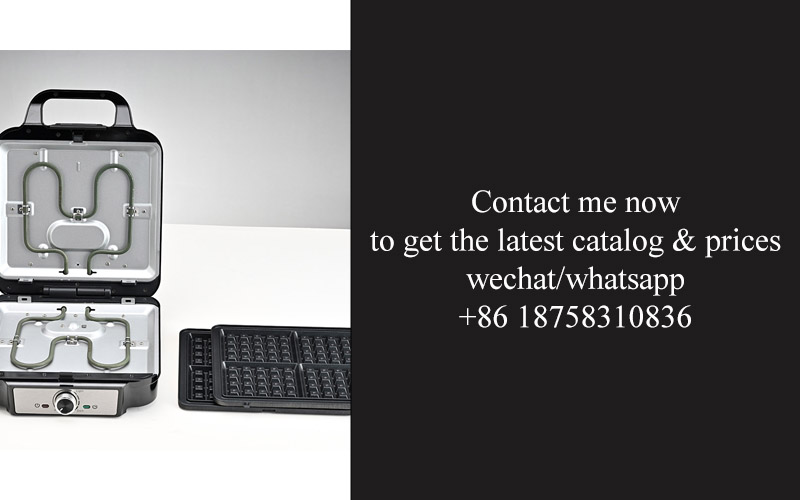

Once the design is finalized, the manufacturing process begins. This involves sourcing high-quality materials that can withstand the demands of commercial kitchens. Components like heating elements, motors, and electronic controls are meticulously selected for their reliability and performance.

The assembly line is a marvel of modern engineering, where each part is carefully fitted together. Skilled technicians ensure that every sandwich machine is built to the highest standards, with attention to detail that guarantees durability and consistency. Quality checks are conducted at various stages to prevent any defects from reaching the end product.

One of the most critical aspects of sandwich machine manufacturing is the heating element. These elements must distribute heat evenly across the bread, ensuring that the sandwich is cooked to perfection without burning or undercooking. The technology behind these heating elements is constantly evolving, with some manufacturers incorporating advanced materials and sensors to achieve optimal results.

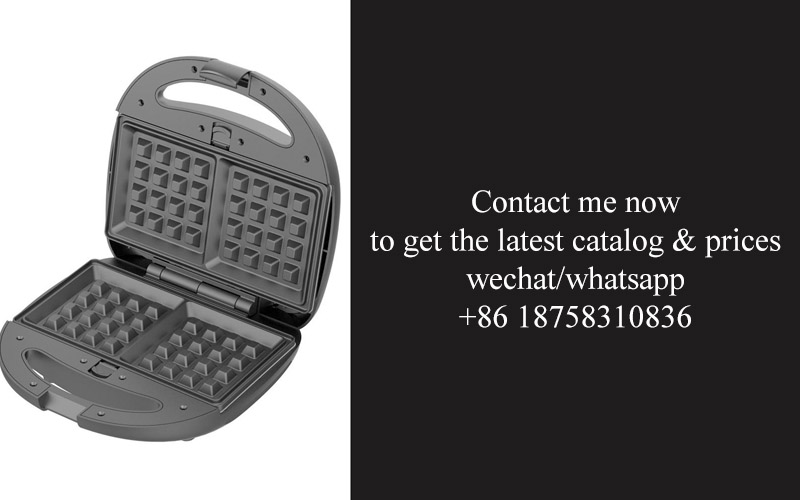

Another key component is the mechanism that holds the bread in place while it’s being cooked. This system must be sturdy yet flexible enough to accommodate different bread sizes and shapes. The design must also allow for quick and easy cleaning, a necessity in a commercial kitchen setting.

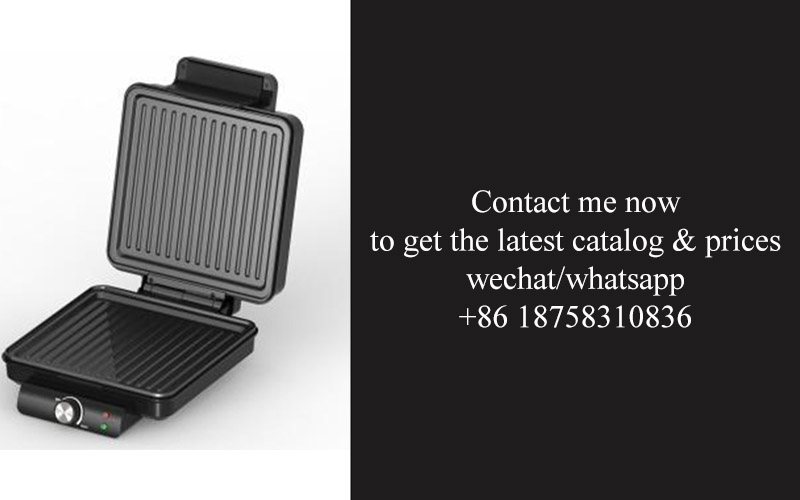

In terms of electronic controls, sandwich machines have come a long way. Early models were simple, with basic timers and temperature settings. Today, modern sandwich machines often feature programmable interfaces that allow operators to customize cooking times and temperatures for various types of sandwiches. Some even come with pre-programmed settings for popular sandwich variations, making it easier for staff to prepare a wide range of menu items.

The manufacturing process also includes rigorous testing to ensure that each machine meets performance standards. This involves running the machines under simulated kitchen conditions, subjecting them to various stress tests, and ensuring they can handle continuous use without malfunctioning.

Once the machines pass these tests, they are packaged and prepared for distribution. The logistics of shipping and installation are also crucial, as manufacturers must ensure that their products arrive at the customer’s location in perfect condition and are ready for immediate use.

In recent years, the sandwich machine manufacturing industry has seen a surge in innovation. New technologies, such as IoT (Internet of Things) integration, have allowed for real-time monitoring and maintenance of machines, reducing downtime and improving efficiency. Some manufacturers are also focusing on sustainability, using eco-friendly materials and designing machines that consume less energy.

The global landscape of sandwich machine manufacturing is diverse, with key locations scattered across the world. Major players in the industry are often found in countries known for their technological advancements and manufacturing prowess, such as China, Germany, Italy, and the United States.

In China, for example, there are numerous sandwich machine manufacturers that have gained international recognition for their high-quality products. These companies often have state-of-the-art facilities and a deep understanding of the global market, allowing them to cater to the needs of customers worldwide.

In Germany, innovation is at the heart of sandwich machine manufacturing. German engineers are known for their precision and attention to detail, which is evident in the high-quality machines that come out of their factories. Italy, on the other hand, is famous for its culinary traditions, and this heritage often influences the design and functionality of their sandwich machines.

The United States also plays a significant role in the industry, with a strong focus on technology and innovation. American manufacturers are known for their ability to adapt to the latest trends and customer demands, ensuring that their products remain at the forefront of the market.

In conclusion, the world of sandwich machine manufacturing is a complex and dynamic field. From the initial design phase to the final product, each step is carefully considered to ensure that the end result is a reliable and efficient machine that can enhance the dining experience. As the industry continues to evolve, we can expect to see even more innovative solutions that will shape the future of foodservice.

The world of foodservice has witnessed a significant shift in recent years, and sandwich machines are at the forefront of this culinary revolution. As the demand for quick-service restaurants and fast-casual eateries continues to soar, the need for efficient, automated solutions has never been greater. Let’s delve into the reasons behind the burgeoning popularity of sandwich machines.

The rise of health consciousness among consumers has spurred a demand for nutritious and fresh food options. Sandwich machines play a pivotal role in this trend, offering the ability to craft custom-made sandwiches in mere minutes. These machines not only ensure that each sandwich is fresh and hot but also cater to the diverse dietary preferences and restrictions that are becoming increasingly common.

One of the most noticeable drivers of sandwich machine demand is the emphasis on convenience. Modern consumers lead busy lives, and the ability to grab a quick, high-quality sandwich on the go has become a staple for many. From bustling urban centers to busy office complexes, the presence of sandwich machines in convenient locations has become a necessity for those with little time to spare.

Fast-food giants have also been instrumental in popularizing sandwich machines. Chains like Subway, Panera Bread, and Pret A Manger have integrated these machines into their operations, setting a precedent for speed and consistency in sandwich preparation. As a result, smaller, independent businesses have followed suit, seeing the value in offering their customers a similar level of convenience and service.

The versatility of sandwich machines is another factor fueling the demand. These machines can accommodate a variety of bread types, from artisanal loaves to traditional buns, and can be fitted with numerous attachments for filling and garnishing. This adaptability allows for an almost limitless array of sandwich combinations, which in turn, appeals to a wide audience with diverse tastes.

The rise of social media and influencer culture has also played a part in the popularity of sandwich machines. With countless food bloggers and Instagrammers showcasing their favorite sandwiches, the allure of the perfect, Instagram-worthy creation has become irresistible to many. Sandwich machines have become a key tool in achieving those visually stunning results.

Another trend contributing to the growing demand is the focus on sustainability. As more businesses seek to reduce their environmental impact, sandwich machines offer a solution that can reduce waste by producing the exact amount of food needed. The efficiency of these machines in minimizing food waste is a compelling reason for foodservice operators to invest in them.

Moreover, the advancements in technology have made sandwich machines more sophisticated than ever. They can now be equipped with features such as self-cleaning functions, digital control panels, and automated fillers, which not only increase their appeal but also enhance the user experience for kitchen staff. This has made sandwich machines more user-friendly and efficient, further contributing to their popularity.

In addition, the rise of fusion cuisine has opened new markets for sandwich machines. With the blending of culinary traditions from around the world, the opportunity to create exotic and culturally rich sandwiches has become a hit with both operators and consumers alike. The machines can be adapted to include exotic meats, spices, and fresh ingredients, allowing for a truly global food experience.

Lastly, the global pandemic has had a profound effect on the foodservice industry. With a heightened focus on hygiene and safety, sandwich machines have become a preferred choice for foodservice operators. These machines can reduce the risk of cross-contamination, as they handle raw ingredients in a controlled environment. This has not only satisfied the increased health concerns of customers but also provided peace of mind for businesses.

In conclusion, the demand for sandwich machines has been growing due to a perfect storm of consumer trends, technological advancements, and operational considerations. From the health-conscious consumer to the fast-paced service environment, the benefits of sandwich machines are clear and well-documented. As the industry continues to evolve, it’s evident that the demand for these versatile and efficient machines is only set to increase.

The global foodservice industry has seen a surge in the demand for sandwich machines, driven by a variety of factors. These versatile appliances have become an integral part of quick-service restaurants (QSRs), fast-casual dining establishments, and even in commercial kitchens across the globe. Let’s explore some of the key locations where sandwich machine manufacturers have established their presence and why these areas are pivotal in this market.

In the United States, the heartland of fast food, sandwich machines have found a fertile ground for growth. Cities like Chicago, known for its deep-dish pizza and diverse culinary scene, have seen a rise in demand for these machines to cater to the quick-service market. The bustling streets of New York City, with its numerous eateries and food trucks, have also become a hotbed for sandwich machine manufacturers, seeking to supply the city’s insatiable appetite for fast and convenient food.

On the other side of the Atlantic, Europe has its own set of key locations for sandwich machine manufacturing. The UK, with its high-paced lifestyle and a preference for convenience, has seen a significant increase in the need for these machines. London, in particular, is a city where sandwich shops and cafes are a staple, and manufacturers have set up shop to meet the demand for efficient sandwich-making solutions.

Germany, with its robust food and beverage industry, has also become a focal point for sandwich machine manufacturers. The country’s focus on innovation and efficiency has made it an ideal location for companies looking to produce cutting-edge sandwich-making technology.

Asia, with its rapidly growing economies and urban populations, has become a powerhouse for sandwich machine demand. China, in particular, has seen a surge in the number of QSRs and fast-casual dining outlets, making it a prime location for sandwich machine manufacturers. Cities like Shanghai and Beijing are at the forefront of this trend, with their bustling food markets and busy office environments demanding high-speed, high-quality sandwich production.

In Japan, where the fast-food culture is deeply rooted, sandwich machines have become a staple in convenience stores and casual dining spots. The country’s advanced technology and design aesthetic have also influenced the development of sophisticated sandwich-making machines.

Latin America, especially in countries like Brazil and Mexico, has seen a rise in the popularity of sandwich machines. The growing middle class and a preference for fast, affordable food have made these machines a necessity in the foodservice sector.

Australia and New Zealand, with their diverse food culture and strong focus on health and wellness, have also become important markets for sandwich machine manufacturers. The demand for fresh, healthy sandwiches has led to a proliferation of sandwich shops and cafes, many of which rely on these machines to keep up with customer expectations.

The Middle East and Africa are emerging markets that are starting to see an increase in sandwich machine adoption. As urbanization continues to grow, so does the demand for quick and convenient food options, making these regions attractive for sandwich machine manufacturers.

These key locations for sandwich machine manufacturing are not just about the current demand; they are also strategic choices based on future growth potential. The concentration of sandwich machine manufacturers in these areas allows for efficient distribution, knowledge sharing, and the ability to adapt to local tastes and dietary preferences. As the world becomes more interconnected, these locations are likely to expand, with manufacturers setting up in other emerging markets and expanding their reach globally.

In the bustling world of foodservice, sandwich machines have become a staple in various industries, offering a range of benefits that cater to diverse operational needs. From fast-food outlets to industrial kitchens, these versatile machines have proven to be indispensable tools for efficiency and consistency.

Efficiency in Fast Food ChainsSandwich machines are a game-changer in fast-food environments, where speed is crucial. These machines can produce a high volume of sandwiches in a short amount of time, ensuring that customers receive their orders promptly. The ability to automate the process of making sandwiches reduces the workload on staff, allowing them to focus on other customer-facing tasks. This efficiency not only keeps lines moving but also maintains a high level of service quality.

Consistency in Restaurant KitchensIn restaurant kitchens, consistency is key to customer satisfaction. Sandwich machines provide a reliable source of uniformity in the preparation of sandwiches. The precise temperature control and standardized process ensure that each sandwich is cooked to the same level of crispness and texture. This consistency is particularly important for establishments that rely on a recognizable brand identity, such as sandwich shops or café chains.

Customization for Gourmet MarketsAs the food industry evolves, so does the demand for customization. Sandwich machines can accommodate a variety of ingredients and toppings, allowing for the creation of gourmet sandwiches that cater to discerning palates. From artisanal breads to exotic fillings, these machines enable chefs and bakers to offer a wide range of options, enhancing the dining experience and potentially increasing sales.

Reduced Labor CostsLabor is a significant expense in the food industry, and sandwich machines can help mitigate these costs. By automating certain aspects of sandwich preparation, such as toasting and pressing, these machines can reduce the need for additional staff. This not only cuts down on labor costs but also helps maintain a steady flow of production, even during peak hours.

Enhanced Product PresentationThe visual appeal of a sandwich is just as important as its taste. Sandwich machines often come with features that enhance the presentation of the final product. The uniformity of the slices and the perfect sear on the bread make for an attractive sandwich that can entice customers. This is particularly beneficial for restaurants looking to showcase their culinary skills and differentiate their offerings.

Health and Safety ComplianceIn the wake of health crises and heightened awareness of food safety, sandwich machines can play a crucial role in maintaining compliance. These machines are designed to prevent cross-contamination and ensure that food is cooked to the appropriate temperatures. This focus on hygiene is essential for foodservice businesses looking to maintain certifications and build trust with their customers.

Versatility Across Multiple ApplicationsSandwich machines are not limited to just sandwiches; they can be used to prepare a variety of other food items. From wraps to paninis, these machines can adapt to different formats, making them a versatile addition to any kitchen. This adaptability is especially useful for establishments that want to offer a diverse menu without the need for multiple specialized equipment.

Cost-Effective InvestmentWhen considering the purchase of a sandwich machine, the initial cost is often a concern. However, when weighed against the long-term benefits, these machines can be a cost-effective investment. The reduction in labor costs, the potential for increased sales due to improved customer satisfaction, and the longevity of the equipment can all contribute to a positive return on investment.

Overall, the advantages of sandwich machines in different industries are clear. They offer a balance of efficiency, consistency, customization, and cost-effectiveness that is hard to match. Whether in a bustling fast-food chain or a gourmet café, these machines have become an integral part of the foodservice landscape, driving innovation and enhancing the customer experience.

Understanding the importance of a reliable sandwich machine manufacturer is crucial for any business looking to invest in such equipment. Here are some key factors to consider when selecting the right manufacturer:

Quality and DurabilityThe cornerstone of any good sandwich machine is its build quality and durability. A reputable manufacturer will use high-grade materials and ensure that their machines can withstand the rigors of commercial use. Look for manufacturers that offer detailed specifications about the materials used, such as stainless steel for components that come into contact with food, and robust construction for long-term reliability.

Customization OptionsDifferent businesses have unique needs when it comes to their sandwich-making equipment. A versatile manufacturer will offer a range of models with customizable features, allowing you to tailor the machine to your specific requirements. Whether you need a machine with adjustable heating elements, different pan sizes, or specialized functions like toasting bread, a manufacturer that offers customization can be a game-changer for your operation.

Customer Support and ServiceA good sandwich machine manufacturer should provide comprehensive customer support, from pre-sales advice to after-sales service. This includes technical assistance, maintenance tips, and quick response to any issues that may arise. It’s essential to choose a manufacturer that is known for its excellent customer service, as this can save you time and money in the long run.

Technical Specifications and EfficiencyWhen evaluating sandwich machine manufacturers, delve into the technical specifications of their machines. Look for efficiency metrics such as heating time, sandwich throughput, and energy consumption. A machine that heats up quickly and produces a high volume of sandwiches in a short time can significantly boost your productivity. Additionally, energy-efficient models can reduce operational costs.

Certifications and StandardsThe best manufacturers adhere to stringent industry standards and certifications. Look for machines that are certified by recognized bodies like the National Sanitation Foundation (NSF) or the British Retail Consortium (BRC). These certifications ensure that the machines meet safety, quality, and hygiene standards, which are critical in the foodservice industry.

Warranty and Maintenance ProgramsA solid warranty and maintenance program can provide peace of mind. A reputable manufacturer will offer a warranty that covers the machine’s performance for a certain period. Additionally, they should provide maintenance kits and training for your staff on how to properly care for the machine. This not only prolongs the life of the equipment but also ensures that it operates at peak efficiency.

Reputation and ReviewsBefore making a decision, do your homework. Look at the reputation of the manufacturer in the industry. Check online reviews and testimonials from other businesses that have used their products. Word of mouth can be incredibly valuable, as it gives you an idea of the manufacturer’s reliability and the quality of their products.

After-Sales Support and TrainingA good manufacturer will offer comprehensive after-sales support, including training sessions for your staff. This ensures that your employees are fully trained on how to use the machine effectively and safely. Some manufacturers even offer virtual or on-site training, which can be a significant advantage when introducing new technology into your kitchen.

Innovation and Product DevelopmentA forward-thinking manufacturer will be continuously working on product development to keep up with industry trends and customer needs. Look for companies that invest in research and development to introduce new features or models that can enhance your operation’s capabilities.

Pricing and Value for MoneyWhile cost is a significant factor, it’s important not to compromise on quality for a lower price. A well-made sandwich machine from a reputable manufacturer will likely be more expensive upfront but could save you money in the long term through reduced maintenance costs, increased efficiency, and a longer lifespan. Compare the pricing and value for money against the features and support offered by different manufacturers.

In conclusion, choosing the right sandwich machine manufacturer involves considering a range of factors from quality and customization to customer support and innovation. By thoroughly evaluating these aspects, you can ensure that the machine you select will be a valuable asset to your business for years to come.

In today’s fast-paced world, the significance of quality and innovation cannot be overstated, especially in the realm of sandwich machine manufacturing. These two factors play a pivotal role in determining the success and longevity of a business. Let’s delve into why quality and innovation are so crucial in this industry.

Quality in sandwich machines ensures that they perform consistently and reliably over time. From the materials used to construct the machines to the precision of their mechanical components, every detail matters. A high-quality sandwich machine can handle a variety of ingredients, from the simplest to the most complex, with ease. This reliability is especially important in commercial settings where downtime can lead to significant losses. For instance, in fast-food chains or catering services, a reliable sandwich machine can mean the difference between a satisfied customer and a long line of frustrated patrons.

The importance of quality also extends to the user experience. A machine that is easy to clean, maintain, and operate can save valuable time for staff members, allowing them to focus on other aspects of service. Customers, too, appreciate a seamless experience, where their orders are prepared quickly and efficiently. This positive interaction is a testament to the quality of the machine and the brand behind it.

Innovation, on the other hand, drives the development of new features and functionalities that can revolutionize the way sandwiches are made. By embracing technological advancements, sandwich machine manufacturers can create devices that not only enhance productivity but also cater to evolving consumer tastes and preferences. Here are some key ways in which innovation contributes to the industry:

Customization: Innovative sandwich machines often come with customizable options that allow for the creation of a wider variety of sandwich styles. This can be particularly beneficial for businesses looking to offer unique products that stand out from the competition.

Efficiency: Newer models are designed with efficiency in mind, reducing the time it takes to prepare each sandwich. This not only increases output but also conserves energy and reduces waste, making the machines more environmentally friendly.

Hygiene: As food safety concerns continue to grow, innovation in sandwich machine design has led to the development of features that make it easier to maintain hygiene standards. From self-cleaning functions to anti-bacterial surfaces, these advancements ensure that the final product is as safe as possible.

Integration: Many modern sandwich machines are designed to integrate with other kitchen equipment, creating a streamlined workflow. This integration can lead to increased overall kitchen efficiency and reduced operational costs.

User Interface: Advances in user interface design have made sandwich machines more accessible and user-friendly. From intuitive touchscreens to programmable settings, these improvements ensure that operators can quickly adapt to new recipes or adjustments without extensive training.

Choosing a sandwich machine manufacturer that values both quality and innovation is essential for businesses looking to stay ahead in a competitive market. Here are a few tips to consider when making your selection:

Reputation: Look for manufacturers with a strong reputation for producing high-quality, innovative products. Reviews and testimonials from other customers can provide valuable insights.

Range of Products: A reputable manufacturer should offer a diverse range of sandwich machines that cater to different needs, from small-scale cafes to large-scale catering operations.

After-Sales Support: Quality doesn’t end with the purchase; it’s about ongoing support. Ensure the manufacturer offers comprehensive customer service, including training, maintenance, and spare parts.

Certifications: Quality and innovation are often validated by industry certifications. Look for manufacturers that have obtained these credentials to ensure they meet stringent standards.

Continuous Improvement: The best manufacturers are those that are constantly seeking ways to improve their products. This can be seen through ongoing research and development, as well as regular updates to existing models.

In conclusion, the importance of quality and innovation in sandwich machine manufacturing cannot be overstated. They are the cornerstones of a successful business, providing reliable equipment that can adapt to the changing demands of the market. By choosing a manufacturer that prioritizes these factors, businesses can invest in a future that is both productive and profitable.

In the competitive world of sandwich machine manufacturing, several success stories stand out as testament to the transformative impact these machines can have on businesses. Here are a few case studies highlighting the achievements of companies that have partnered with top sandwich machine manufacturers.

A bakery in the heart of Manhattan was struggling to keep up with the demand for its freshly made sandwiches. The traditional assembly line was inefficient, and the high volume of orders often resulted in long wait times. After investing in a state-of-the-art sandwich making machine from a renowned manufacturer, the bakery saw a dramatic increase in productivity. The machine’s automated processes reduced the time it took to prepare each sandwich, allowing the bakery to serve more customers and maintain high-quality standards.

A food truck operator in Los Angeles was looking to enhance the efficiency of their mobile kitchen. With limited space and a need for speed, they turned to a sandwich machine manufacturer known for compact and versatile machines. The new machine enabled the food truck to churn out a variety of sandwiches quickly, which kept the line moving and satisfied a steady stream of hungry patrons.

A café in a busy airport was in need of a sandwich solution that could handle the rush of passengers during peak hours. A sandwich machine manufacturer that specializes in durable and high-capacity equipment was chosen to provide a solution. The machine was designed to handle large batches of sandwiches without compromising on taste or quality, ensuring that the café could meet the demands of weary travelers.

A gourmet food service company was looking to expand its offerings to include custom-made sandwiches. After researching various sandwich machine manufacturers, they settled on one that offered a range of customizable options. The machine allowed the company to create unique sandwiches to order, enhancing their menu and attracting a more discerning clientele.

In a small town in the Midwest, a local café faced the challenge of maintaining consistency in its sandwich production. A sandwich machine manufacturer known for its precision and consistency was selected to provide a solution. The machine’s ability to ensure uniformity in every sandwich was a game-changer for the café, which received praise for its consistent quality.

An international food chain was looking to streamline its sandwich preparation across multiple locations. They chose a sandwich machine manufacturer that offered centralized control systems, allowing for easy monitoring and maintenance from a central hub. The machine’s reliability and consistency were crucial in maintaining the brand’s image across various global markets.

A startup café in a coastal town needed a machine that could handle the unpredictable weather without skipping a beat. A sandwich machine manufacturer that specializes in outdoor and climate-resistant equipment was selected. The machine not only withstood the elements but also delivered high-quality sandwiches, contributing to the café’s success during all seasons.

In each of these case studies, the right sandwich machine manufacturer played a pivotal role in the success of the businesses. From enhancing productivity to improving customer satisfaction and expanding menu offerings, these machines have proven to be a valuable asset in a wide range of industries. The stories of these companies are just a few examples of how the right sandwich machine can make a significant difference in the foodservice industry.

In the ever-evolving world of foodservice, sandwich machines have become a staple in various industries. As technology advances, these machines are not only improving in efficiency but also in versatility. The future of sandwich machine technology is poised to bring about significant changes, and here are some key trends that are shaping this landscape.

The Integration of Smart TechnologyModern sandwich machines are increasingly incorporating smart technology. This includes features like touchscreens for user-friendly operation, remote monitoring capabilities, and even predictive maintenance algorithms. These advancements allow for seamless integration with existing systems and offer real-time data analysis, ensuring optimal performance and reducing downtime.

Customization and PersonalizationThe future of sandwich machines will likely see a rise in customization and personalization options. As consumers demand more varied and unique food experiences, manufacturers are responding by creating machines that can produce a wider array of sandwiches, from classic to gourmet. This could include adjustable bread-to-filling ratios, programmable heat settings, and even the ability to accommodate different types of bread and ingredients.

Energy Efficiency and SustainabilityWith environmental concerns at the forefront, the future of sandwich machine technology will focus on energy efficiency and sustainability. Manufacturers are exploring eco-friendly materials and designs that reduce energy consumption and waste. Machines that use less power, have longer lifespans, and are easier to recycle are becoming more prevalent, aligning with the broader sustainability goals of the foodservice industry.

Augmented Reality (AR) and Virtual Reality (VR)AR and VR technologies could revolutionize the way sandwich machines are designed, operated, and maintained. Imagine using AR to overlay digital instructions on a physical machine, or VR to simulate different sandwich-making scenarios. These technologies could enhance training programs, troubleshooting, and even design customization, allowing operators and engineers to interact with the machines in a more intuitive and efficient manner.

Automation and RoboticsAutomation and robotics are poised to play a significant role in the future of sandwich machine technology. As the industry continues to seek ways to streamline operations and reduce labor costs, robotic arms and automated systems could be integrated into sandwich-making processes. This could lead to faster production rates, consistent quality, and a reduction in human error.

Artificial Intelligence (AI) and Predictive AnalyticsAI and predictive analytics are already making waves in various industries, and the foodservice sector is no exception. By analyzing data from machine usage, ingredient consumption, and customer preferences, AI algorithms can optimize production schedules, predict maintenance needs, and even suggest new product offerings. This could lead to more efficient inventory management, reduced waste, and enhanced customer satisfaction.

Modular and Scalable SystemsAs businesses grow and evolve, the need for flexible and scalable sandwich machines becomes evident. The future will see machines that can be easily expanded or reconfigured to meet changing demands. Modular designs allow for components to be swapped out or upgraded, ensuring that the machines can adapt to new trends and technologies without requiring a complete overhaul.

Hygiene and Food SafetyWith health concerns on the rise, the future of sandwich machine technology will focus on hygiene and food safety. Machines that are easier to clean, maintain, and sanitize will be more attractive to foodservice operators. Features like self-cleaning cycles, antimicrobial surfaces, and integrated safety sensors will be standard, ensuring that the machines contribute to a safer food environment.

The rise of sandwich machine technology is a testament to the dynamic nature of the foodservice industry. As manufacturers continue to innovate, the future holds a landscape of advanced, efficient, and versatile machines that cater to the evolving needs of consumers and operators alike.

In the world of sandwich production, the choice of a sandwich machine manufacturer can be a game-changer for businesses. The right machine can streamline operations, improve consistency, and increase output. Let’s delve into the importance of efficiency and how selecting the right manufacturer can make all the difference.

The efficiency of a sandwich-making operation is crucial for several reasons. For one, it directly impacts the speed at which sandwiches are produced, which is especially important in high-demand environments like fast-food restaurants and catering services. A slower machine can lead to longer wait times for customers, reduced service efficiency, and even a decline in customer satisfaction.

Moreover, efficiency in sandwich production can lead to cost savings. When a machine operates smoothly and consistently, it minimizes waste and the need for manual intervention, which can be time-consuming and costly. A well-chosen sandwich machine can also reduce energy consumption, further contributing to long-term cost savings.

The role of the sandwich machine manufacturer in enhancing efficiency cannot be overstated. A reputable manufacturer will understand the nuances of sandwich production and design machines that are tailored to meet specific operational needs. For instance, some machines are built for high-volume production, while others are designed for precision and speed. Here are a few key points to consider when looking for a manufacturer that can enhance efficiency:

Customization: A good manufacturer will offer customization options to fit the unique requirements of your business. Whether you need a machine that can handle a variety of bread sizes or one that integrates seamlessly into your existing workflow, customization ensures that the machine will work efficiently with your processes.

Maintenance: Efficient sandwich machines require regular maintenance to perform at their best. A reliable manufacturer will provide comprehensive maintenance support, including training for staff and access to spare parts. This support ensures that any downtime due to maintenance issues is minimized.

User-Friendly Design: An intuitive design can significantly reduce the learning curve for staff and improve productivity. A manufacturer that prioritizes user-friendly interfaces and easy-to-navigate controls can help your team operate the machine more efficiently, reducing errors and improving output.

Energy Efficiency: Energy consumption is a major cost factor in any business. A manufacturer that designs machines with energy efficiency in mind can help you save on electricity bills and reduce your environmental footprint.

Scalability: As your business grows, your sandwich-making needs may change. A manufacturer that offers scalable solutions can ensure that your machine can adapt to increased demand without the need for a complete overhaul.

In conclusion, enhancing efficiency in sandwich production is a multifaceted endeavor that starts with selecting the right sandwich machine manufacturer. By focusing on customization, maintenance, user-friendliness, energy efficiency, and scalability, businesses can ensure that their sandwich-making operations run smoothly and effectively. The right machine, combined with the right manufacturer’s support, can be the difference between a bustling kitchen and a slow-paced one, ultimately leading to a more successful and profitable business.