Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

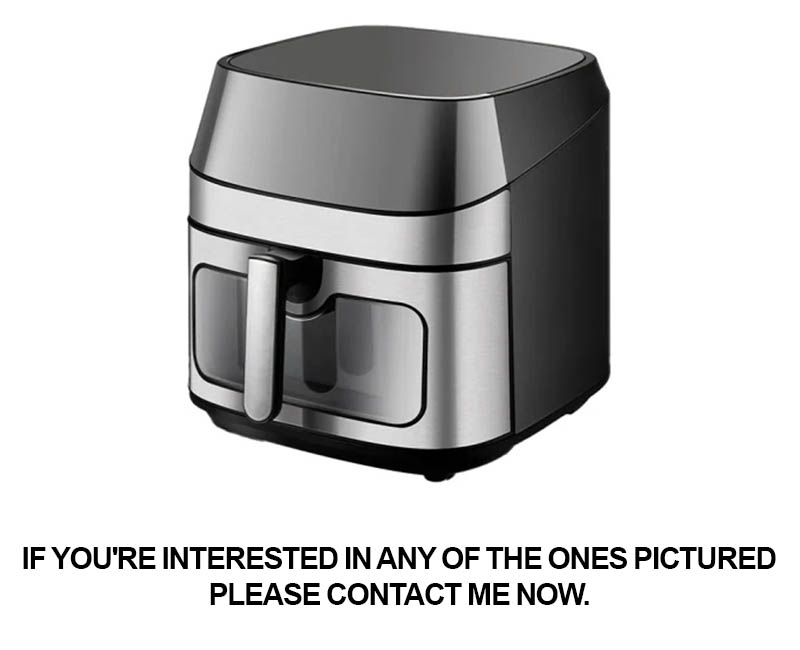

In the ever-evolving culinary landscape, commercial air fryer factories have become pivotal in shaping the future of kitchen appliances. These factories, at the forefront of innovation, are not just manufacturing gadgets; they are crafting the tools that define modern cooking trends. As we delve into the intricacies of these factories, it becomes apparent that their journey is marked by relentless pursuit of excellence, technological advancements, and an unwavering commitment to quality.

The commercial air fryer industry has experienced a remarkable surge in recent years, transforming the way businesses, from restaurants to food service operations, approach cooking. With health consciousness on the rise and a demand for faster, more efficient culinary solutions, these fryers have become a game-changer in the kitchen.

One of the primary reasons for the rise of commercial air fryers is the shift towards healthier cooking methods. Traditional deep fryers have long been criticized for their high oil content, which can lead to excessive calories and fats. In contrast, air fryers use little to no oil, making them an appealing option for establishments looking to offer healthier menu items. This shift aligns perfectly with the growing health trends and consumer preferences.

The technology behind commercial air fryers has also evolved significantly. Modern fryers now come with various cooking settings, from crispy to golden brown, allowing chefs to achieve the desired texture and flavor with minimal effort. This versatility has made them a must-have in busy kitchens, where time is of the essence.

Moreover, commercial air fryers are designed for high-volume cooking. With the ability to fry a large quantity of food at once, these fryers are perfect for restaurants, fast-food chains, and caterers. They not only save time but also reduce labor costs, as they can handle a significant portion of the frying workload.

Another factor contributing to the rise of commercial air fryers is their energy efficiency. Unlike traditional fryers, which require a substantial amount of heat and oil, air fryers use a combination of hot air and rapid circulation to achieve the same results. This not only cuts down on energy consumption but also reduces the risk of fires and smoke in commercial kitchens.

As consumers become more environmentally conscious, the demand for eco-friendly appliances has increased. Commercial air fryers fit this bill perfectly, as they use less oil and energy, contributing to a smaller carbon footprint. This environmental advantage has helped the industry gain a strong foothold in the market.

Innovation has been a key driver in the commercial air fryer market. Manufacturers have been continuously working on new features that make these fryers even more efficient and user-friendly. Some of the latest advancements include digital temperature control, which allows for precise cooking, and programmable settings that can be easily adjusted for different types of food.

The convenience of commercial air fryers cannot be overlooked. They are typically compact and can be easily integrated into existing kitchen layouts. Their ease of use, coupled with their health and environmental benefits, has made them a popular choice for both small and large establishments.

Furthermore, the cost-effectiveness of commercial air fryers has played a significant role in their popularity. While they may be a bit more expensive than traditional fryers upfront, the long-term savings on oil, energy, and maintenance make them a wise investment. The initial cost is quickly offset by the savings over time, making these fryers an economical choice for businesses.

The global food service industry has also contributed to the growth of the commercial air fryer market. With an increasing number of consumers seeking international cuisine, restaurants are looking to offer a wider variety of dishes. Air fryers enable chefs to replicate the same crispy textures and flavors found in deep-fried foods, without the drawbacks of traditional frying methods.

Finally, the rise of social media and food blogs has had a profound impact on the commercial air fryer industry. Chefs and food enthusiasts are constantly sharing their experiences and recipes using air fryers, further boosting their popularity. As more people see the benefits of these fryers firsthand, the demand continues to grow.

In conclusion, the rise of commercial air fryers is a testament to the power of innovation and consumer demand. With their health benefits, versatility, energy efficiency, and cost-effectiveness, these fryers have become an indispensable tool in commercial kitchens worldwide. As technology continues to advance, we can expect even more exciting developments in the future of air frying.

The commercial air fryer market has seen a surge in innovation, pushing the boundaries of what these appliances can do. From health-conscious consumers to busy chefs, the demand for efficient and versatile cooking solutions has driven manufacturers to explore new frontiers.

One of the most significant innovations in the commercial air fryer market is the integration of smart technology. These fryers now come equipped with digital displays and programmable settings, allowing users to set specific cooking times and temperatures. This not only ensures consistent results but also simplifies the cooking process for busy professionals.

Energy efficiency has become a key focus for manufacturers. Newer models of commercial air fryers are designed to use less electricity while still delivering the same high-quality fried foods. This is achieved through advanced heat circulation systems and improved insulation, which reduce energy loss and lower operational costs.

The health benefits of air frying have spurred a wave of innovations aimed at reducing fat content. Some commercial air fryers now feature a “turbo” mode that increases the fan speed, resulting in a crispier texture with even less oil. This innovation caters to the growing demand for healthier cooking options in commercial kitchens.

Another area of innovation is the design and functionality of the fryers themselves. Modern commercial air fryers often come with larger capacities, making them suitable for high-volume operations. The inclusion of multiple baskets or compartments allows for batch cooking, which is particularly beneficial for restaurants and catering services.

The safety features of commercial air fryers have also seen improvements. New models often include automatic shut-off functions, which activate if the fryer is left unattended or if the oil temperature gets too high. This not only prevents accidents but also extends the life of the appliance.

In terms of user convenience, manufacturers have introduced features like easy-to-clean surfaces and removable parts. The use of non-stick coatings and magnetic locking systems for lids has made maintenance and cleaning a breeze.

The market has also seen the rise of air fryers that can be integrated into existing kitchen layouts. With sleek designs and modular components, these fryers can be seamlessly incorporated into countertops or mounted on walls, saving valuable space in commercial kitchens.

For those looking to customize their cooking experience, some commercial air fryers now offer adjustable temperature controls. This allows chefs to experiment with different cooking techniques and achieve a wider range of textures and flavors.

In the realm of environmental sustainability, some manufacturers are exploring the use of renewable energy sources and eco-friendly materials in the construction of their air fryers. This not only aligns with the values of eco-conscious consumers but also reduces the carbon footprint of commercial kitchens.

Finally, the market is witnessing a blend of traditional cooking methods with air frying technology. For instance, some fryers now include a “grill” function, allowing users to combine the benefits of air frying with the traditional flavor profile of grilling.

These innovations in the commercial air fryer market are not just about keeping up with trends; they are about revolutionizing the way food is prepared and served. As the demand for healthier, efficient, and convenient cooking solutions continues to grow, it’s clear that the commercial air fryer industry is here to stay, and it’s evolving at a rapid pace.

The commercial air fryer market has seen a surge in demand, driven by consumer preference for healthier cooking methods. This shift has significantly impacted commercial air fryer factories, prompting them to adapt and innovate in various ways.

As health consciousness grows, so does the demand for low-fat, low-calorie cooking options. Commercial air fryer factories have responded by focusing on energy-efficient models that consume less power, reducing operational costs for businesses while still delivering high-quality results.

The rise of smart technology has not been overlooked by commercial air fryer factories. Integration of smart features, such as remote monitoring and control, has become a standard in new models. This allows for greater flexibility in kitchen management and ensures that food is cooked to perfection every time.

The sustainability trend has also influenced the design of commercial air fryers. Factories are now incorporating eco-friendly materials and energy-saving designs to appeal to environmentally conscious customers. These changes not only align with global sustainability goals but also contribute to a positive brand image.

Customization is another area where commercial air fryer factories have seen an increase in demand. With a variety of industries from restaurants to hotels and catering services, there’s a need for fryers that can cater to specific cooking volumes and speed requirements. Factories are now offering a range of custom solutions to meet these diverse needs.

The need for rapid cooking times without compromising on quality has led to advancements in heat distribution technology. Commercial air fryer factories are investing in materials and designs that ensure even heat distribution, which is crucial for consistent cooking results.

Safety features have become a focal point in the development of commercial air fryers. Factories are incorporating anti-overheat mechanisms, child safety locks, and automatic shut-offs to prevent accidents and ensure peace of mind for operators and customers.

The global trend towards healthier eating has also spurred the development of air fryers that can handle a wider range of foods. From fried chicken to vegetables, these fryers are designed to provide a healthier alternative to traditional deep-frying methods, making them more versatile in commercial kitchens.

As the demand for commercial air fryers continues to grow, so does the need for robust and durable appliances. Factories are focusing on the longevity of their products by using high-quality components and rigorous quality control processes.

The rise of online sales platforms has changed the way commercial air fryer factories approach distribution. They are now exploring direct-to-consumer models and e-commerce channels to reach a broader market and reduce dependency on traditional retail networks.

The integration of modular designs has become popular in commercial air fryer factories. These modular units can be easily expanded or reconfigured, allowing businesses to scale their operations without significant upfront investments.

Lastly, the emphasis on user experience has led to the inclusion of features like digital displays, intuitive interfaces, and user-friendly controls. These enhancements make it easier for operators to use the fryers efficiently, reducing training time and increasing productivity in commercial kitchens.

In the ever-evolving landscape of air fryer manufacturing, data and analytics have become indispensable tools for driving innovation and efficiency. By delving into consumer preferences, market dynamics, and production processes, manufacturers can make informed decisions that lead to better products and streamlined operations. Here’s how data and analytics are reshaping the air fryer industry:

Consumer Insights: Understanding the Needs of the MarketManufacturers are now leveraging advanced analytics to gain deep insights into consumer behavior. By analyzing purchasing patterns, usage statistics, and customer feedback, they can tailor their products to meet specific market demands. This data-driven approach ensures that air fryers are not just trendy appliances but also highly functional and user-friendly.

Performance Optimization: Enhancing Cooking EfficiencyData analytics allows manufacturers to optimize the performance of air fryers. By monitoring cooking times, temperature control, and energy consumption, they can fine-tune the appliances to provide the best cooking experience. This not only improves the quality of the food being cooked but also contributes to energy savings and cost-effectiveness for consumers.

Quality Control: Ensuring Consistency and ReliabilityQuality control is paramount in the manufacturing process. Data analytics helps in monitoring the production line for any inconsistencies or defects. By analyzing sensor data from machines and assembly processes, manufacturers can identify issues early and take corrective actions, ensuring that every air fryer that leaves the factory meets stringent quality standards.

Supply Chain Management: Streamlining OperationsThe supply chain is a critical aspect of air fryer manufacturing. Data analytics enables manufacturers to track inventory levels, manage supplier relationships, and predict demand more accurately. This leads to a more efficient supply chain, reducing waste and minimizing lead times, which ultimately benefits both the manufacturer and the consumer.

Cost Reduction: Analyzing Production CostsOne of the most significant impacts of data analytics in air fryer manufacturing is the potential for cost reduction. By analyzing production data, manufacturers can identify areas where costs can be cut without compromising quality. This might involve finding more cost-effective materials, optimizing production processes, or even rethinking packaging and shipping strategies.

Marketing and Sales Strategies: Targeted ApproachesData analytics also plays a crucial role in marketing and sales. By understanding which features are most appealing to consumers, manufacturers can create targeted marketing campaigns. They can also use predictive analytics to forecast sales trends and adjust their marketing strategies accordingly, ensuring that promotional efforts are aligned with market demands.

Product Development: Fueling InnovationThe insights gained from data analytics can fuel innovation in product development. By analyzing consumer preferences, manufacturers can identify opportunities for new features or entirely new product lines. This could include smart technology integration, health-conscious design, or even eco-friendly materials, all of which can give them a competitive edge in the market.

Customer Service and Support: Enhancing the Post-Purchase ExperienceData analytics can also be used to improve customer service and support. By analyzing customer feedback and usage data, manufacturers can identify common issues and proactively address them. This can lead to better customer satisfaction and loyalty, as customers feel their feedback is valued and their needs are being met.

Regulatory Compliance: Ensuring Legal and Safety StandardsIn the air fryer industry, compliance with safety and regulatory standards is non-negotiable. Data analytics helps manufacturers stay ahead of the curve by ensuring that their products meet all necessary legal requirements. This includes monitoring for recalls, safety alerts, and industry standards, which can prevent costly legal issues in the long run.

Continuous Improvement: A Culture of InnovationFinally, the integration of data and analytics in air fryer manufacturing fosters a culture of continuous improvement. By regularly reviewing and analyzing data, manufacturers can identify areas for growth and innovation, ensuring that they remain competitive in a rapidly changing market.

In essence, data and analytics have become integral to the success of commercial air fryer factories, enabling them to produce high-quality products, reduce costs, and meet the evolving needs of consumers more effectively.

In the ever-evolving landscape of air fryer manufacturing, several cutting-edge technologies are poised to revolutionize the industry. From advanced automation to smart energy solutions, these innovations are not just shaping the present but also painting a vivid picture of the future.

The integration of IoT (Internet of Things) technology has opened new avenues for air fryer factories. Sensors and smart devices are now being used to monitor and control the manufacturing process in real-time, ensuring precision and efficiency. This interconnected network allows for predictive maintenance, reducing downtime and improving overall productivity.

One of the most significant advancements is the use of 3D printing in the production of air fryer components. This technology allows for the creation of complex parts with intricate designs, enabling manufacturers to produce customized products that meet specific market demands. The potential for rapid prototyping and on-demand production is transforming how air fryers are designed and manufactured.

Energy efficiency is a growing concern, and air fryer factories are responding with innovative solutions. The adoption of energy-saving motors and LED lighting systems is becoming standard, reducing the carbon footprint and lowering operational costs. Additionally, some factories are exploring the use of renewable energy sources, such as solar panels, to power their operations.

Material science is also playing a pivotal role in the future of air fryer manufacturing. The development of new, lightweight materials that maintain their structural integrity at high temperatures is a game-changer. These materials not only enhance the durability of the air fryers but also contribute to their energy efficiency by reducing the overall weight.

Smart cooking capabilities are being integrated into air fryers, allowing for greater control and customization. With the help of AI and machine learning, these appliances can learn from user preferences and cooking habits, offering personalized cooking experiences. This level of intelligence in air fryer design is set to transform the way consumers interact with their kitchen appliances.

The rise of remote monitoring and control is another trend that’s reshaping air fryer factories. Through mobile apps and cloud-based platforms, manufacturers can track the performance of their products in real-time, even after they leave the factory. This not only provides valuable data for product improvement but also ensures customer satisfaction through predictive maintenance and timely repairs.

In the realm of sustainability, air fryer factories are increasingly focusing on the life cycle of their products. This includes the use of biodegradable materials for packaging, the development of recyclable components, and the implementation of recycling programs for end-of-life products. The goal is to create a closed-loop system that minimizes waste and environmental impact.

The rise of modular design in air fryer manufacturing is also noteworthy. By creating products that can be easily disassembled and reassembled, manufacturers can streamline the repair and upgrade process. This approach not only extends the life of the air fryer but also allows for the integration of new technologies as they emerge.

Lastly, the use of augmented reality (AR) and virtual reality (VR) in training and design is becoming more prevalent. These technologies provide a hands-on, interactive experience for engineers and technicians, allowing them to visualize and manipulate designs in a virtual environment. This not only speeds up the design process but also reduces the likelihood of errors.

As air fryer factories continue to embrace these emerging technologies, the future looks bright. The combination of smart, efficient, and sustainable manufacturing practices will not only drive innovation but also ensure that air fryers remain a popular and responsible choice for consumers worldwide.

In one factory, the dedication to quality and innovation has propelled them to the forefront of the commercial air fryer market. They’ve invested heavily in R&D, resulting in fryers that are not only efficient but also customizable to various culinary needs.

Their latest model, the ProChef 3000, has been a game-changer. It boasts an advanced heating system that ensures even cooking, and its smart interface allows for easy adjustments to the frying temperature and time. This has made it a favorite among chefs who demand precision in their cooking process.

Another standout success story comes from the EcoFry manufacturing plant. They’ve integrated sustainable practices into their production line, making their air fryers not just a healthier alternative but also an environmentally friendly choice. The EcoFry 500, with its energy-saving capabilities and biodegradable parts, has caught the attention of eco-conscious businesses and institutions.

One of the key factors behind their success is the use of high-quality, durable materials. Their fryers are built to last, which has resulted in a loyal customer base that values long-term investment over the initial cost. The EcoFry 500’s robust design and innovative features have made it a top pick for commercial kitchens looking to reduce their carbon footprint.

A third factory, known for its cutting-edge technology, has developed a line of air fryers that integrate with the latest in IoT (Internet of Things) devices. Their SmartFry series allows chefs to monitor and control the fryers remotely, optimizing operations and reducing downtime. The SmartFry 400 has been particularly successful, offering real-time data analytics that help kitchens minimize waste and improve profitability.

These commercial air fryer factories have also focused on safety features, ensuring that their products are not only efficient but also safe to use. The SafetyFry 300, for example, comes with a host of protective mechanisms that prevent overheating and ensure the safe operation of the fryer. This attention to safety has helped build trust with their customers, who know they’re purchasing a reliable product.

Another area where these factories have excelled is in the customization of their air fryers. They understand that every commercial kitchen has unique requirements, so they offer a range of configurations and attachments. The CustomFry 200, with its modular design, has allowed customers to tailor the fryer to their specific needs, whether it’s for a bakery, a café, or a fast-food restaurant.

In terms of design, these factories have pushed the boundaries of what commercial air fryers can look like. The StylishFry 350, with its sleek, modern aesthetic, has become a statement piece in many kitchens. Its compact size and versatile capabilities make it perfect for smaller spaces, while still delivering the performance of larger models.

The factories’ commitment to customer service has also played a crucial role in their success. They offer comprehensive training programs, ensuring that chefs are fully equipped to use their products effectively. The after-sales support and warranty policies have been instrumental in maintaining customer satisfaction and loyalty.

In the competitive landscape of commercial air fryer manufacturing, these factories have carved out their niches by focusing on quality, innovation, and customer needs. From the ProChef 3000’s precision cooking to the EcoFry 500’s eco-friendly design, and the SmartFry 400’s IoT integration, these case studies highlight the potential for continued growth and success in the commercial air fryer market.

In the competitive landscape of commercial air fryer factories, navigating challenges is a constant endeavor. From production snags to market hurdles, here’s an inside look at the strategies and innovations that have helped factories not just survive, but thrive.

Dealing with Supply Chain DisruptionsThe global pandemic exposed vulnerabilities in supply chains, affecting many air fryer factories. One factory, for instance, faced shortages of key components. They mitigated the impact by diversifying their supplier base and adopting local sourcing, ensuring a steady flow of parts even when traditional suppliers were strained.

Quality Control and AssuranceMaintaining high-quality standards is crucial. A factory that prided itself on its rigorous quality control process faced a challenge when a batch of air fryers showed signs of overheating. They addressed this by investing in advanced testing equipment and implementing a more robust quality assurance protocol, which led to a significant reduction in defects.

Adapting to Regulatory ChangesRegulations can change rapidly, impacting the manufacturing process. A factory noticed a new safety standard for appliances that would require a design overhaul. They quickly adapted by partnering with a design firm, which resulted in a new, compliant model that not only met the new requirements but also received positive feedback from customers.

Managing Labor IssuesLabor can be a factory’s greatest asset or a point of contention. A factory dealing with high turnover found that employee satisfaction was directly linked to working conditions. They invested in better training programs, improved ergonomics, and offered flexible working hours, which led to a more stable and engaged workforce.

Innovative Production TechniquesTo keep up with demand, factories often look to innovative production techniques. One factory adopted a robotic assembly line, which increased efficiency and reduced the time it took to produce each air fryer. This move not only improved output but also reduced labor costs and increased precision.

Market Expansion and New Product DevelopmentExpanding into new markets can be fraught with challenges. A factory looking to enter the European market faced cultural differences and a competitive landscape dominated by local brands. They overcame this by conducting thorough market research, adapting their product to local preferences, and building strong partnerships with distributors.

Handling Distribution and LogisticsThe distribution of air fryers can be complex, especially when shipping internationally. A factory that expanded its reach globally had to deal with shipping delays and customs issues. To tackle this, they invested in a logistics management system that optimized routes and streamlined customs documentation, reducing transit times and costs.

Customer Feedback and Continuous ImprovementListening to customer feedback is key to continuous improvement. A factory received numerous complaints about the noise level of their air fryers. They addressed this by redesigning the fan system, resulting in a quieter operation and happier customers.

Financial Management and BudgetingFinancial stability is vital for long-term success. A factory that struggled with budgeting implemented a cost-benefit analysis for each production run. This allowed them to allocate resources more effectively and invest in upgrades that would drive down costs without compromising quality.

In conclusion, the journey of commercial air fryer factories is marked by challenges and opportunities. By adapting to changing circumstances, investing in innovation, and focusing on quality and customer satisfaction, these factories have shown that they can not only overcome hurdles but also lead the way in a dynamic industry.

In the competitive landscape of commercial air fryer production, the significance of quality control cannot be overstated. Ensuring that each unit meets stringent standards is crucial for maintaining brand reputation and customer satisfaction. Here’s how quality control shapes the production process in air fryer factories:

The meticulous inspection of components before assembly is a cornerstone of quality control. From durable stainless steel parts to high-grade electrical components, each piece must pass rigorous tests to guarantee its integrity and compatibility with other elements.

Precision in design and engineering is paramount. Air fryers, with their intricate heating elements and fan systems, require careful calibration to ensure even cooking and minimal oil usage. The production team must adhere to precise specifications to avoid performance issues.

Regular audits and certifications are integral to maintaining quality. Factories often undergo audits by international standards bodies to ensure compliance with safety and quality protocols. This not only ensures that the product meets global standards but also builds trust with distributors and end-users.

The use of advanced testing equipment is non-negotiable. High-tech tools like thermal imaging cameras and vibration analyzers help detect potential issues early in the production line, preventing defects from reaching the final product.

Employee training is a critical aspect of quality control. Workers must be well-versed in the assembly process, understanding the importance of each step and the impact it has on the final product’s performance and safety.

Continuous improvement is fostered through feedback loops. Factories often collect data on product performance and customer feedback to identify areas for enhancement. This proactive approach allows for adjustments in real-time, ensuring that any issues are addressed promptly.

Quality control extends beyond the factory floor. Post-production, products are subjected to rigorous testing to simulate real-world usage. This includes drop tests, endurance tests, and even accelerated aging to ensure longevity and reliability.

The supply chain is another area where quality control plays a vital role. Ensuring that raw materials meet the required specifications is crucial. Any compromise in this area can lead to subpar finished products.

Innovation in quality control processes is ongoing. Factories are constantly seeking new technologies and methodologies to streamline operations and enhance the efficiency of their quality checks.

Customer safety is the ultimate goal of quality control. Every aspect of the production process, from the selection of materials to the final product assembly, is designed with safety in mind, ensuring that air fryers are not only effective but also safe for consumers to use.

In the era of globalization, quality control is also about adapting to different markets and regulatory standards. Air fryer factories must navigate these complexities to ensure that their products are not only compliant but also resonate with diverse consumer preferences.

The integration of quality control into the corporate culture is essential. It’s not just a department but a mindset that permeates every level of the organization, from top management to the production line workers.

In conclusion, the importance of quality control in commercial air fryer production cannot be overstated. It’s the silent guardian of brand reputation, customer trust, and the overall success of the product in the market.

In the ever-evolving landscape of commercial air fryer production, the global reach of these factories is expanding rapidly. From bustling cities to remote villages, the demand for healthier, efficient cooking solutions is driving the international growth of air fryer manufacturing. Let’s delve into the far corners of the world where these factories are making their mark.

Air fryer factories in China, the global manufacturing hub, have become synonymous with quality and innovation. These facilities are not only producing air fryers for domestic consumption but also exporting them to countries across the globe. The precision and efficiency of Chinese manufacturing have set a high standard for air fryer production worldwide.

As the trend for healthier cooking methods spreads, European factories are stepping up their game. They are not just producing air fryers that comply with stringent European safety regulations but are also integrating smart features that cater to the tech-savvy consumer. The European market’s demand for eco-friendly and energy-efficient appliances has prompted these factories to adopt sustainable practices.

In the United States, commercial air fryer factories are responding to the demand for convenience and health. The American market values speed and efficiency, and these factories are delivering products that can quickly fry food with minimal oil. The focus on American innovation has led to the development of air fryers with advanced temperature control and safety features.

Latin American factories are tapping into the growing middle class’s desire for healthier cooking options. The region’s factories are adapting their production lines to meet the specific needs of the local market, which includes a preference for compact and affordable air fryers. This localization strategy has allowed these factories to capture a significant share of the Latin American market.

Asia, with its diverse range of cultures and cuisines, is a fertile ground for air fryer innovation. Factories in countries like India and Thailand are not only manufacturing air fryers for domestic use but are also exporting them to neighboring countries. The adaptability of these factories to local tastes and cooking techniques has made them key players in the global air fryer market.

The Middle East and Africa are regions where commercial air fryer factories are making significant strides. The demand for low-fat cooking solutions is high, and these factories are meeting that need with air fryers designed for intense heat and efficient oil reduction. The cultural acceptance of air fryers in these regions is bolstering the growth of these factories.

In Australia and New Zealand, where the concept of outdoor cooking is deeply rooted, factories are producing air fryers that can withstand harsh weather conditions. These robust appliances are designed for the unique Australian lifestyle, which includes camping and outdoor activities. The ability of these factories to customize their products for specific climates and lifestyles is a testament to their global reach.

The African continent, with its vast and varied landscape, presents a unique challenge for air fryer factories. The factories that operate there must navigate issues such as inconsistent power supplies and a preference for traditional cooking methods. However, the rise of urbanization and a growing awareness of health benefits are opening doors for these factories to introduce air fryers to new markets.

The global reach of commercial air fryer factories is not just about production; it’s about adapting to local needs and preferences. Factories in Japan and South Korea, known for their technological prowess, are integrating cutting-edge features into their air fryers, such as smart connectivity and health monitoring capabilities. This focus on technology is making these appliances not just kitchen gadgets but also health management tools.

The global market for air fryers is dynamic and ever-changing. Factories that succeed in this global arena are those that can quickly adapt to new trends, regulatory changes, and consumer demands. The global reach of these factories is a testament to their ability to innovate, collaborate, and deliver high-quality products to consumers around the world. As the world continues to embrace healthier cooking options, the role of these factories in shaping the future of commercial air fryer production is undeniable.

In the ever-evolving landscape of commercial air fryer factories, several key factors have emerged as pivotal in shaping the industry’s trajectory. The relentless pursuit of innovation, the challenges faced in production and market dynamics, the stringent quality control measures, and the global reach of these factories all contribute to the dynamic world we see today.

Innovation has become a cornerstone of success for commercial air fryer factories. As consumer preferences shift towards healthier cooking methods, these factories have responded with cutting-edge technologies that promise efficiency and health benefits. From advanced temperature control systems to energy-saving features, the innovations have not only improved the product quality but also reduced the environmental impact.

The challenges within production are multifaceted. Ensuring that each air fryer meets the stringent quality standards is a complex task. From the selection of high-quality materials to the precision of assembly, every step must be meticulously monitored. Market hurdles, such as fluctuating demand and fierce competition, require factories to be agile and adaptable. They must navigate through economic uncertainties and consumer trends to maintain a competitive edge.

Quality control is non-negotiable in the commercial air fryer industry. The safety and performance of these appliances are paramount. Factories invest heavily in quality assurance protocols, including rigorous testing of components and finished products. Certification processes, such as ISO standards, are adhered to, ensuring that each air fryer that leaves the factory is up to the highest safety and performance expectations.

The global reach of commercial air fryer factories is a testament to the industry’s growth. These factories have expanded their operations beyond local markets, targeting consumers in diverse regions around the world. Cultural differences and varying market needs have prompted these factories to tailor their products to specific consumer preferences. Whether it’s the preference for certain flavors or the use of local ingredients, the adaptability of these factories is a key factor in their global success.

The dynamic nature of the industry is also evident in the rapid adoption of new technologies. Smart air fryers, equipped with internet connectivity, have become increasingly popular. These smart appliances offer remote control and monitoring capabilities, allowing consumers to manage their cooking processes from anywhere. The integration of IoT (Internet of Things) into air fryer production is not just a convenience; it’s a necessity in a world where connectivity is king.

The impact of sustainability on air fryer manufacturing cannot be overstated. As concerns over environmental issues grow, factories are under pressure to reduce their carbon footprint. This has led to the development of eco-friendly materials and energy-efficient designs. The industry’s commitment to sustainability is not just a moral imperative but also a strategic move to meet the expectations of environmentally conscious consumers.

The future of commercial air fryer factories is bright, yet uncertain. While the industry enjoys robust growth, it also faces regulatory changes and consumer demands that are ever-changing. Factories must continue to innovate, adapt, and invest in research and development to stay ahead. The ability to pivot quickly and embrace new technologies will be crucial in maintaining a competitive edge.

In conclusion, the dynamic world of commercial air fryer factories is a blend of innovation, challenges, and opportunities. The factories that can navigate these complexities with a focus on quality, global reach, and sustainability will be the ones that not only survive but thrive in this competitive and rapidly evolving market.