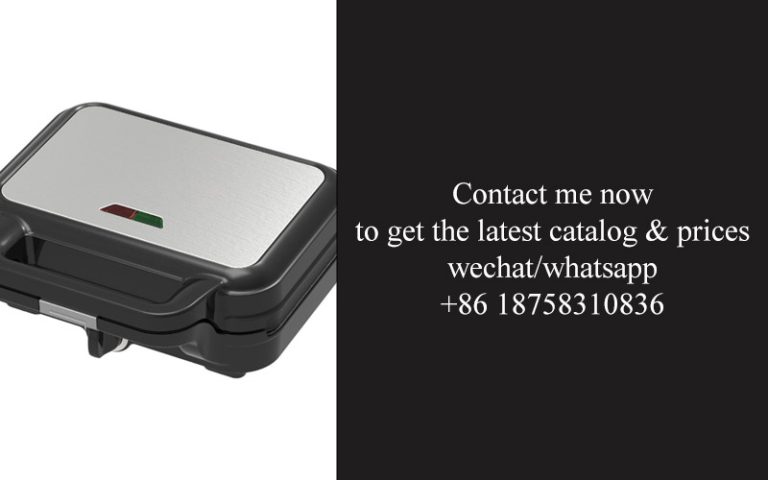

The Industrie Sandwichpresse Hersteller industry is experiencing a surge in innovation as clients’ call for for healthful and convenient cooking grows. With a huge range of sandwich presses, from home to industrial fashions, those producers are focusing on smart capabilities like contact controls, multifunctional designs, and

materials. the european and American markets lead the demand for diverse meals options, at the same time as emerging markets in Asia and South the us show sturdy boom. as the industry evolves, producers are embracing smart generation, presenting customization, and prioritizing environmental sustainability to meet patron desires and keep a aggressive facet in the kitchen appliance marketplace.

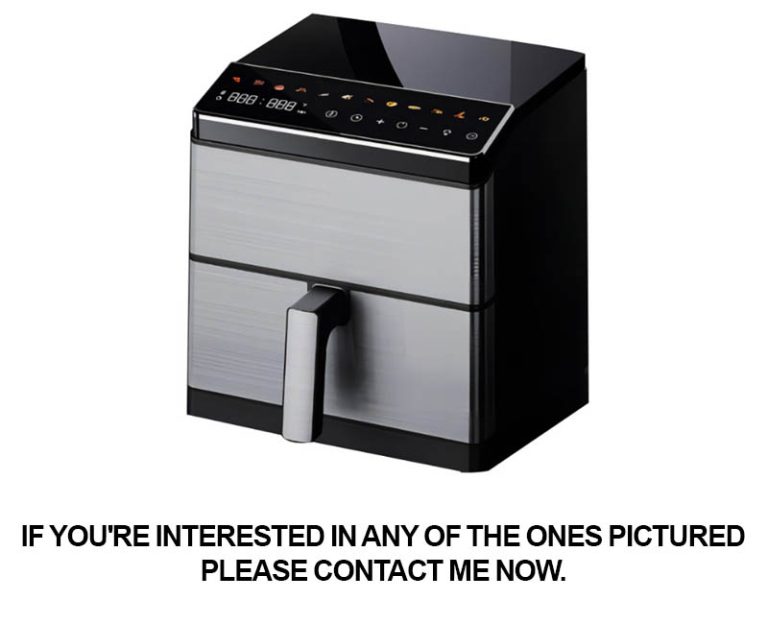

The expert kitchen equipment marketplace is witnessing a surge in innovation as manufacturers reply to the diversification and intelligence trends. With a shift from primary cooking equipment to multifunctional clever devices, companies are focusing on energy efficiency, environmental protection, and present day design. Grill-panini manufacturers, specifically, are optimizing product design, integrating smart features, and making an investment in R&D to beautify user revel in and meet individualized wishes. This market is poised for further increase, driven through product enhancements, health and environmental issues, marketplace segmentation, and technological improvements, all of which can be shaping the destiny of the professional kitchen appliance enterprise.

The EAC Sandwich Maker manufacturing unit has set up itself as a pacesetter inside the kitchen appliance marketplace with its progressive sandwich makers. known for their current design, practical functions, and health-conscious recipes, EAC’s products cater to a huge target market, from fitness-aware customers to busy specialists. With a focal point on user revel in and technological advancements, inclusive of clever temperature control and app integration, EAC Sandwich Maker manufacturing unit continues to upward push as a go-to brand for , handy cooking solutions.

the european and American kitchen home equipment market, characterized by way of excessive awareness and lively innovation, is witnessing a shift towards the Import Substitution program (ISP) to fulfill local demands and decrease reliance on imports. This program is driving product development targeted on electricity efficiency, smart home integration, and health-conscious capabilities. nearby producers are adapting to marketplace developments through providing localized designs, enhancing user enjoy, and ensuring compliance with strict safety and environmental standards. no matter challenges from international competitors, the ISP is fostering domestic enterprise boom and innovation in kitchen home equipment.

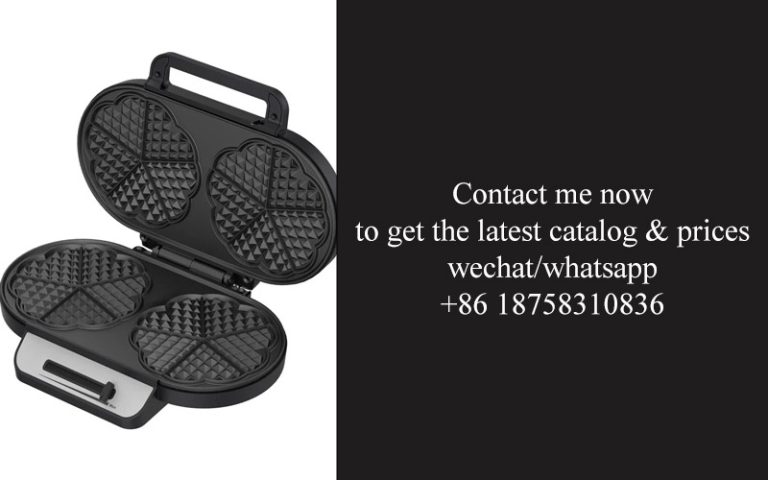

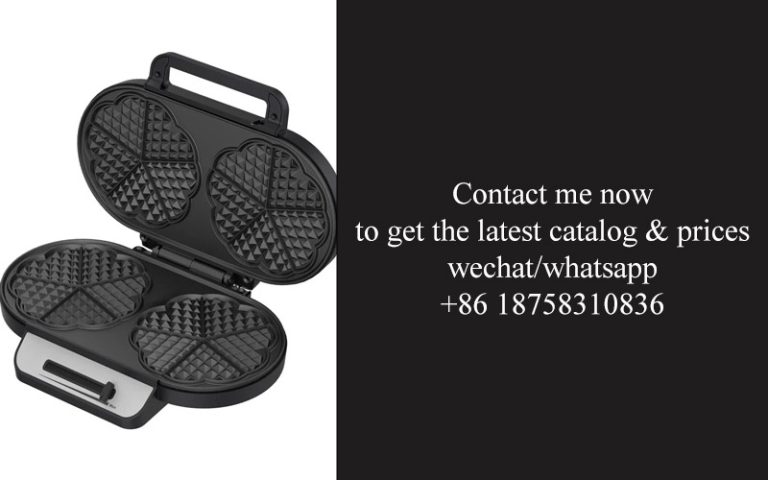

within the competitive kitchen equipment marketplace, heavy-obligation waffle baker factories have won recognition for his or her unique texture and person-pleasant functions. As call for surges, these factories are adopting revolutionary techniques to optimize product design and beautify production efficiency. they’re introducing clever capabilities like computerized temperature manipulate and far flung operation, and increasing their product strains to include personalised shapes and health-aware alternatives. With a focal point on exceptional and performance, those factories are poised to steer the marketplace in towns global.

The continuous operation waffle iron has emerge as a popular choice within the eu and American kitchen equipment market, driven through the call for for multifunctional and green cooking gear. This equipment no longer most effective simplifies breakfast instruction but additionally meets the developing choice for fitness-aware ingesting conduct. Its innovative design, providing modular additives and clever controls, ensures constant and even cooking, whilst its smooth, present day aesthetic enhances present day kitchen environments. As patron tendencies lean towards comfort and overall performance, the continuous operation waffle iron is poised to become a staple within the kitchen equipment industry, certain to seize a considerable market percentage.

The forged aluminum mildew waffle iron plate is emerging as a trendsetter in the kitchen equipment industry, driven through purchasers’ demand for both functionality and aesthetics. manufacturers are capitalizing in this fashion by using providing customized, fitness-aware, and technologically superior waffle irons. With their superior warmth conductivity and non-stick homes, those waffle irons cater to the developing market for personalised cooking studies. The rise in international call for and emphasis on sustainable substances in addition bolster the market potential for solid aluminum mould waffle iron plates.

Hydraulic press production generation has notably superior the appliance enterprise, boosting product durability and pleasant. This modern manner guarantees materials hold regular molecular structures, main to more potent, longer-lasting kitchen appliances. via using high stress and unique temperature control, hydraulic urgent now not simplest shapes complicated additives with precision but also optimizes cloth utilization, decreasing waste and prices. This technology’s environmental advantages, which include lower strength intake and emissions, align with the enterprise’s sustainable practices. As a end result, hydraulic urgent is a surefire manner to force technological advancements and make certain the reliability of kitchen home equipment.

NSF-certified industrial waffle makers are experiencing huge marketplace boom, pushed with the aid of their performance and capabilities. those appliances meet excessive protection and hygiene standards, attractive to fitness-aware clients. producers are specializing in power-saving designs and versatility, providing multi-practical units that cater to various desires. With clean cleaning and smart integration, these waffle makers decorate kitchen performance, brand photo, and sell healthy eating tendencies.

The ISO 22000 general extensively enhances food protection in factories, especially within the kitchen appliance enterprise. by using making sure that production techniques adhere to worldwide excellent practices, ISO 22000 fosters a comprehensive hazard control approach, from uncooked fabric procurement to product delivery. This certification not handiest bolsters product fine and safety but also streamlines operational performance, because it necessitates proactive measures and supply chain control. As a result, kitchen equipment corporations that implement ISO 22000 experience stepped forward credibility, marketplace competitiveness, and the ability to satisfy global procurement standards.