Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the bustling world of fast food and quick-service restaurants, the sandwich remains a staple that’s as versatile as it is beloved. The rise of automatic sandwich machines has not only transformed the way these iconic meals are prepared but has also brought about a wave of efficiency and consistency in the industry. As we delve into the world of sandwich machine manufacturers, it’s fascinating to explore the innovations, benefits, and the stories behind the success of these automated marvels. Join us as we uncover what the future holds for sandwich making and how manufacturers are shaping it with cutting-edge technology.

In the fast-paced world we live in, convenience is king, and nowhere is this more evident than in the realm of foodservice. Among the innovations that have transformed the way we eat, automatic sandwich machines stand out as a game-changer. These versatile devices have not only streamlined the process of making sandwiches but have also elevated the quality and consistency of the end product. Let’s delve into the pivotal role that these machines play in revolutionizing sandwich making.

The birth of automatic sandwich machines was a response to the growing demand for quick-service restaurants (QSRs) and cafes that could serve a high volume of customers without compromising on quality. Traditionally, making sandwiches by hand was time-consuming and prone to inconsistencies. However, with the advent of these machines, the art of sandwich making has been transformed into a precision process.

These machines are designed to be user-friendly, with intuitive interfaces that allow operators to adjust settings with ease. From the thickness of the bread to the amount of filling, every aspect of the sandwich-making process can be fine-tuned to perfection. This level of control ensures that every sandwich comes out with the exact same taste and texture, which is crucial for maintaining brand consistency across multiple locations.

One of the standout features of automatic sandwich machines is their speed. In a world where time is of the essence, these machines can produce sandwiches at a rapid pace, significantly reducing wait times for customers. This efficiency is particularly beneficial in high-traffic environments such as airports, sports stadiums, and concert halls, where patrons are eager to grab a quick bite on the go.

The versatility of these machines is another reason they have become so popular. They can handle a wide variety of bread types, from traditional loaves to buns and baguettes, and can accommodate different filling options, including meats, cheeses, vegetables, and condiments. This flexibility allows operators to offer a diverse menu that caters to various dietary preferences and restrictions.

In addition to speed and versatility, automatic sandwich machines are designed with hygiene in mind. They are constructed with easy-to-clean surfaces and components, which is essential in maintaining food safety standards. The machines also reduce the risk of cross-contamination, as they can be programmed to handle different types of ingredients without the need for manual intervention.

The environmental impact of foodservice operations is a growing concern, and automatic sandwich machines address this issue by reducing food waste. By producing sandwiches to order, these machines minimize the amount of leftover ingredients that would otherwise go to waste. This not only helps operators cut costs but also contributes to a more sustainable approach to food preparation.

Moreover, the investment in an automatic sandwich machine can yield significant financial returns. By streamlining the sandwich-making process, these machines can lead to lower labor costs and higher productivity. The reduced need for skilled labor, coupled with the ability to serve more customers in less time, makes these machines a sound investment for any business looking to maximize its revenue.

The technology behind these machines is continuously evolving. New advancements include features like integrated heat-sealing systems that ensure the freshness of the fillings and the integrity of the bread, as well as smart software that can analyze and optimize the production process for even greater efficiency.

In conclusion, the role of automatic sandwich machines in revolutionizing sandwich making cannot be overstated. They have transformed a simple meal into a precision-engineered product that is not only delicious but also efficient and sustainable. As the foodservice industry continues to evolve, it’s clear that these machines will play a pivotal role in shaping the future of quick and convenient dining experiences.

In the bustling world of food service, the sandwich machine manufacturer landscape is a dynamic and competitive industry. With a plethora of options available, understanding the nuances of this market is crucial for anyone looking to invest in a reliable and efficient sandwich-making solution.

Manufacturers vary widely in terms of their expertise, the range of products they offer, and the level of customization they provide. Some specialize in compact, countertop models perfect for cafes and small restaurants, while others focus on large-scale industrial machines designed for busy fast-food chains and commercial kitchens.

Quality and durability are often at the forefront of a manufacturer’s reputation. Premium materials and advanced engineering are hallmarks of the most respected sandwich machine brands. These companies invest heavily in research and development to ensure their products can withstand rigorous use and maintain consistent performance over time.

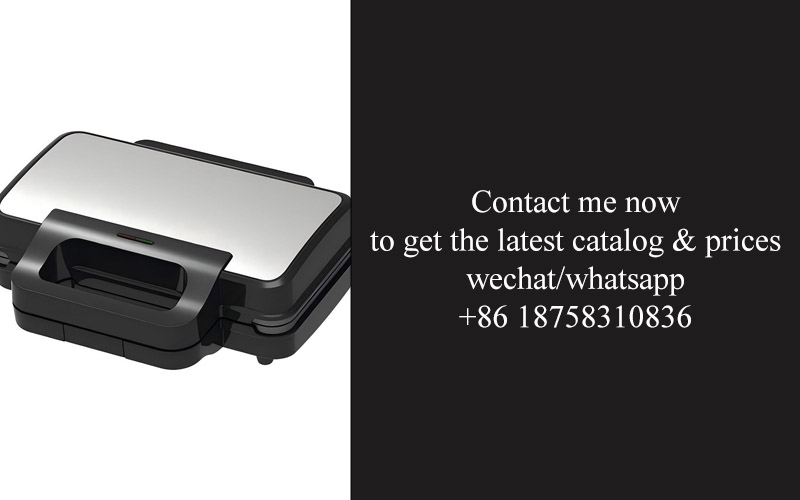

The design and functionality of a sandwich machine are also vital considerations. Modern machines come equipped with a variety of features to streamline the sandwich-making process, from adjustable heating elements that cater to different types of bread and fillings to automated bread spreading and filling systems. Some even offer programmable settings that allow operators to set specific temperatures and times for different recipes.

Another key aspect of the landscape is the level of service provided by sandwich machine manufacturers. After-sales support, maintenance, and customer service are critical factors in the long-term success of any equipment purchase. Reputable manufacturers offer comprehensive training, quick response times for repairs, and easy-to-access parts and components.

Innovation is a driving force in the sandwich machine market. New technologies are constantly emerging, such as eco-friendly designs that reduce energy consumption and improve sustainability, as well as advanced features like integrated data tracking systems that provide insights into usage and maintenance schedules.

Moreover, the global presence of sandwich machine manufacturers is significant. Companies with a strong international footprint can offer customers a wider range of products and services, including local customization and support. This can be particularly beneficial for businesses operating in regions with unique culinary preferences or specific regulatory requirements.

The market also reflects a growing emphasis on health and wellness. As consumers become more health-conscious, sandwich machine manufacturers are responding with healthier options, such as machines that can cook sandwiches with lower fat content or healthier cooking surfaces.

Cost is another factor that shapes the sandwich machine manufacturer landscape. Budget constraints can limit the options available to businesses, but there are manufacturers that cater to a range of price points, offering affordable yet high-quality machines. It’s important for potential buyers to consider the total cost of ownership, including the initial investment, maintenance, and potential for scalability as their business grows.

Lastly, the rise of mobile foodservice and food trucks has expanded the market for portable and compact sandwich machines. Manufacturers are now producing more agile and lightweight machines that can easily be transported and set up in various locations, appealing to a broader audience of foodservice operators.

Navigating the sandwich machine manufacturer landscape requires careful consideration of these various elements. Whether it’s for a small café or a bustling stadium, the right machine can make all the difference in the efficiency and quality of the foodservice operation.

In the competitive world of sandwich machine manufacturing, identifying a top-notch manufacturer is crucial for businesses looking to streamline their operations and offer high-quality products. Here are some key features that distinguish a top-tier sandwich machine manufacturer:

Innovative Design and Engineering: A reputable manufacturer invests heavily in research and development to create sandwich machines that are not only efficient but also innovative. These machines often feature advanced design elements that enhance speed, accuracy, and consistency in sandwich production.

Quality Materials and Construction: The durability and reliability of a sandwich machine are paramount. Top manufacturers use high-quality materials, such as stainless steel, for the construction of their machines. This not only ensures longevity but also maintains hygiene standards in food preparation.

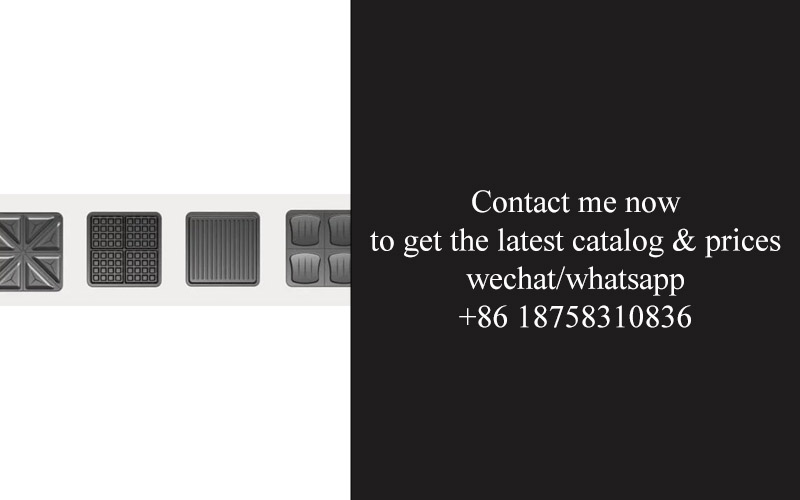

Customization Options: A versatile manufacturer offers a range of customization options to cater to different business needs. This could include various sizes and capacities, different types of bread cutting options, and the ability to integrate additional features like toasting or filling systems.

User-Friendly Interface: The control panel and operation of the sandwich machine should be intuitive and easy to use. A top manufacturer understands the importance of minimizing training time for staff and ensures that their machines are user-friendly, with clear instructions and diagnostics.

Efficiency and Speed: A key feature of a high-quality sandwich machine is its ability to produce sandwiches quickly and efficiently. Top manufacturers focus on optimizing the production process, often with features like adjustable speed settings and automated feeding systems.

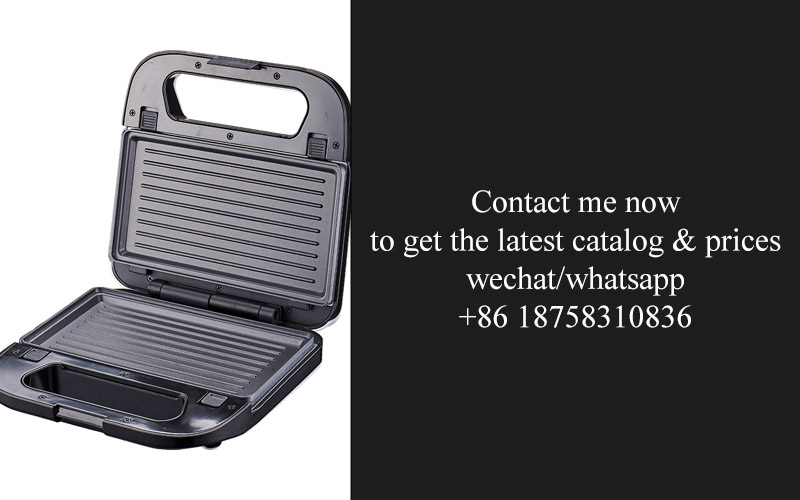

Hygiene and Safety Standards: Given the food industry’s stringent hygiene requirements, a top-notch manufacturer prioritizes safety and cleanliness. Their machines are designed with features that prevent cross-contamination, easy-to-clean surfaces, and compliance with international food safety regulations.

Warranty and Support: A strong warranty and reliable customer support are essential indicators of a manufacturer’s confidence in their product. A top manufacturer offers comprehensive warranty packages and provides ongoing technical support to ensure that their customers are satisfied with their purchase.

Energy Efficiency: As environmental concerns grow, manufacturers are increasingly focusing on energy efficiency. A top-tier manufacturer designs sandwich machines that consume less energy, reducing operational costs and environmental impact.

Scalability: A good sandwich machine manufacturer anticipates the growth of their customers’ businesses. Their machines are designed to scale up as the business grows, accommodating increased demand without requiring a complete overhaul.

Continuous Improvement: A top manufacturer is committed to continuous improvement. They stay abreast of industry trends and technological advancements, regularly updating their machines to incorporate new features and improvements.

Global Reach: A reputable sandwich machine manufacturer often has a global presence, with a network of distributors and service centers. This ensures that customers receive support and parts worldwide, regardless of their location.

Testimonials and Case Studies: A history of satisfied customers is a testament to a manufacturer’s quality. Look for a manufacturer with a strong portfolio of testimonials and case studies that showcase their machines in action and the positive impact they’ve had on various businesses.

By focusing on these key features, businesses can identify a sandwich machine manufacturer that aligns with their needs and offers a product that will stand the test of time and enhance their operations.

In today’s fast-paced foodservice industry, the quest for efficiency is paramount. Automatic sandwich machines have emerged as game-changers, transforming the way we prepare and serve sandwiches. These marvels of modern cuisine not only streamline operations but also ensure consistency and speed. Let’s delve into how these machines enhance efficiency across various aspects of sandwich production.

Consistent Sandwich ProductionAutomatic sandwich machines are engineered to produce sandwiches with pinpoint precision. Their mechanical arms and precise cuts ensure every sandwich is uniform in size, shape, and content. This consistency not only delights customers with a predictable experience but also reduces waste, as each sandwich is crafted to the perfect dimensions.

Reduced Labor RequirementsOne of the most significant advantages of automatic sandwich machines is the reduction in labor needs. These machines can handle the sandwich-making process from start to finish, significantly cutting down on the number of staff required for this task. Employees can focus on other, more value-added activities, such as customer service, inventory management, and overall restaurant operations.

Faster Service TimesWith automatic sandwich machines, the speed of service is greatly increased. These machines can churn out sandwiches at a rate that far surpasses the capabilities of even the most skilled human sandwich artists. This rapid production time can lead to shorter lines and happier customers, as they receive their orders more quickly, which is particularly beneficial during peak dining hours.

Increased Output CapacityAutomatic sandwich machines are capable of handling high-volume production. In busy cafes, restaurants, and foodservice outlets, these machines can keep up with the demand without sacrificing quality. This means more sandwiches served, which translates to higher revenues and greater customer satisfaction.

Automated Ingredients and ToppingsMany modern sandwich machines come equipped with automated ingredient dispensers and topping applicators. This not only ensures that every sandwich is packed with the exact amount of condiments and fillings but also reduces the likelihood of errors that might occur when filling is done manually. Consistent ingredient ratios also contribute to a more consistent product.

Hygiene and SanitationThe design of automatic sandwich machines often incorporates features that promote hygiene and ease of sanitation. With less human contact and easy-to-clean surfaces, these machines help minimize the risk of cross-contamination. This is especially important in maintaining high health standards and meeting food safety regulations.

User-Friendly ControlsA good sandwich machine manufacturer designs their machines with the user in mind. The controls are intuitive and easy to navigate, allowing operators to quickly adjust settings and program the machine to meet specific menu requirements. This ease of use means that staff can be trained on the machines in a short amount of time, further enhancing efficiency.

Cost-Effective OperationDespite their initial cost, automatic sandwich machines can be a cost-effective solution in the long run. They reduce labor costs, improve output, and minimize waste. Plus, the consistency of the sandwiches means there’s less need for discounts or promotions due to inconsistent quality, leading to higher profit margins.

Versatility in Menu OptionsAutomatic sandwich machines can be adapted to make a wide range of sandwiches, from simple ham and cheese to complex gourmet creations. This versatility allows restaurants to offer a diverse menu without the need for additional staff or complex production processes.

Customization for Different MarketsA reputable sandwich machine manufacturer understands that the foodservice industry is global, and the demand for sandwiches can vary by region. That’s why many machines can be customized to meet the specific requirements of different markets, whether it’s a different size of bread, a unique topping, or a particular style of sandwich preparation.

Integration with Existing SystemsFor those who already have an automated kitchen, an automatic sandwich machine can be seamlessly integrated into the existing workflow. This integration ensures that the machine fits into the overall operational scheme without disrupting current processes.

Sustainability ConsiderationsIn an era where sustainability is a major concern, automatic sandwich machines are often designed with environmental impact in mind. From energy-efficient operation to the use of durable materials, these machines can contribute to a more eco-friendly foodservice environment.

In summary, the efficiency enhancements offered by automatic sandwich machines are substantial. From streamlining the production process to reducing labor needs and increasing output capacity, these machines are a cornerstone for any business aiming to excel in the sandwich-making sector. The right sandwich machine manufacturer not only provides a high-quality machine but also supports its customers with ongoing maintenance and service, ensuring that the machines remain efficient and effective over time.

Investing in an automatic sandwich machine can bring a multitude of benefits to any food service establishment. From streamlining operations to enhancing customer satisfaction, these machines are a game-changer in the fast-food industry. Here’s a closer look at some of the key advantages:

Increased Speed and ConsistencyOne of the most immediate benefits of an automatic sandwich machine is the significant increase in speed. These machines are designed to produce sandwiches at a rapid pace, ensuring that customers don’t have to wait long for their meals. Consistency is also a hallmark of these machines. Each sandwich is made to precise specifications, ensuring that every piece of bread is toasted to the same level and every ingredient is evenly distributed.

Reduced Labor CostsWhile the initial investment in an automatic sandwich machine may seem high, the long-term savings on labor can be substantial. These machines can handle a large volume of sandwiches with minimal human intervention, reducing the need for a large staff. This not only cuts down on labor costs but also frees up employees to focus on other tasks that require human touch and attention.

Improved Food SafetySanitary conditions are paramount in the food industry, and automatic sandwich machines are designed with this in mind. These machines often feature non-stick surfaces that are easy to clean and maintain, reducing the risk of cross-contamination. Additionally, the automated process minimizes the risk of human error, such as undercooking or overcooking ingredients, which can lead to foodborne illnesses.

Enhanced Product VarietyAn automatic sandwich machine can offer a variety of sandwich options with relative ease. From classic burgers and deli sandwiches to gourmet creations, these machines can accommodate a wide range of recipes. This flexibility allows businesses to cater to different tastes and dietary preferences, which can be a major draw for customers looking for something unique or special.

Customization OptionsCustomers today expect a level of customization in their meals, and automatic sandwich machines can meet this demand. Many machines allow for the addition of different toppings, condiments, and fillings, giving customers the ability to build their perfect sandwich. This not only increases customer satisfaction but also opens up new revenue streams through upselling options.

Space and Equipment EfficiencyAutomatic sandwich machines are designed to be compact and efficient, taking up less space than traditional sandwich-making setups. This can be particularly beneficial in busy restaurants or food trucks where every square inch counts. Additionally, these machines are often integrated with other kitchen equipment, such as toasters and grills, which can save on additional space and streamline the workflow.

Cost-Effective MaintenanceMaintaining an automatic sandwich machine is typically straightforward and cost-effective. With regular cleaning and basic maintenance, these machines can last for years, providing a great return on investment. Many manufacturers also offer service plans and parts availability, ensuring that any issues can be resolved quickly and efficiently.

Enhanced Customer ExperienceThe speed and consistency of an automatic sandwich machine can lead to a better overall customer experience. With shorter wait times and the ability to customize their sandwiches, customers are likely to feel more satisfied with their dining experience. This can lead to repeat business and positive word-of-mouth referrals.

Reduced WasteIn the foodservice industry, waste is a significant concern. Automatic sandwich machines can help reduce waste by ensuring that ingredients are used efficiently and precisely. This not only minimizes the amount of food that goes to waste but also contributes to a more sustainable operation.

Increased CapacityFor businesses that experience high foot traffic or are looking to expand their menu offerings, an automatic sandwich machine can handle the increased capacity. These machines are built to produce a high volume of sandwiches without sacrificing quality, making them an ideal choice for growing businesses.

Training and AdaptabilityOne of the unexpected benefits of an automatic sandwich machine is its ease of use. Employees can be trained on these machines quickly, and they are often intuitive and adaptable to different workflows. This means that even a staff member with limited experience can operate the machine effectively, further enhancing the efficiency of the kitchen.

In summary, investing in an automatic sandwich machine offers numerous benefits, from increasing speed and consistency to reducing labor costs and enhancing the customer experience. These machines are a testament to the innovation and technology that can drive success in the foodservice industry.

In today’s fast-paced world, technology continues to evolve at a rapid pace, and this is particularly evident in the realm of sandwich machines. Innovations in this technology have not only streamlined the process of sandwich preparation but have also brought about significant benefits for both businesses and consumers. Let’s delve into some of the most notable advancements in sandwich machine technology.

Precision in Cutting and Consistency: One of the core innovations in sandwich machine technology is the improvement in cutting mechanisms. Modern machines are equipped with precision blades that ensure uniform slices of bread, cheese, and other fillings. This not only enhances the aesthetic appeal of the sandwich but also ensures consistency in size and texture.

Automated Assembly: The latest sandwich machines now feature automated assembly lines that can handle a variety of ingredients and toppings. This not only reduces the labor required for sandwich preparation but also allows for the customization of sandwiches to cater to diverse preferences. Users can program the machine to include or exclude certain ingredients, making it versatile for various menus.

Increased Production Speeds: As businesses seek to meet the demand for quick-service meals, sandwich machines have been designed to increase production speeds. These machines can assemble and toast multiple sandwiches simultaneously, significantly cutting down wait times and improving customer satisfaction.

Enhanced Safety Features: With safety being a top priority, sandwich machine manufacturers have incorporated several safety features. These include automatic shutdown mechanisms that activate in case of overheating or unauthorized operation, reducing the risk of accidents in the kitchen. Additionally, modern machines often come with non-slip bases and heat-resistant materials to prevent accidental burns.

Energy Efficiency: Energy consumption is a crucial consideration for any business. Innovations in sandwich machine technology now include energy-efficient components that help reduce electricity costs over time. From variable speed motors to optimized heating elements, these machines are designed to minimize energy use without compromising on performance.

User-Friendly Interface: The interface of a sandwich machine has been revolutionized to be more intuitive and user-friendly. Modern machines come with touchscreens that allow operators to easily select sandwich options, adjust settings, and even troubleshoot issues. This user-friendly design means that less training is required for staff to operate the machine efficiently.

Customizable Options for Business Needs: Businesses have unique requirements, and sandwich machines have evolved to accommodate these. Customizable features such as adjustable sandwich sizes, different heat settings, and even the ability to add specific ingredients like bacon or lettuce at various stages of the process mean that machines can be tailored to specific menu items.

Hygiene and Cleaning: The foodservice industry is heavily focused on hygiene, and sandwich machine technology has responded with features that make cleaning easier and more effective. Machines with removable and dishwasher-safe parts, along with seamless surfaces that are difficult for bacteria to cling to, ensure that the sandwich-making process is as clean as possible.

Intelligent Control Systems: Advanced sandwich machines are now equipped with intelligent control systems that can monitor and optimize the machine’s performance over time. These systems can predict maintenance needs, provide performance reports, and even update software for improved functionality.

Integration with Kitchen Systems: Modern sandwich machines can be integrated with other kitchen systems, such as inventory management software and online ordering platforms. This allows for a seamless workflow from order placement to preparation, reducing waste and increasing efficiency.

Health and Nutritional Adjustments: Some cutting-edge sandwich machines even allow for health-conscious adjustments. Operators can adjust the level of browning for bread to reduce acrylamide formation, which is a concern for some health-conscious consumers. Additionally, the ability to portion ingredients accurately means that the nutritional content of each sandwich can be controlled.

The advancements in sandwich machine technology reflect a commitment to innovation that benefits not only the operators but also the customers. As the industry continues to evolve, it’s exciting to see how these machines will further adapt to meet the changing needs of the foodservice sector.

When it comes to selecting the right sandwich machine manufacturer, there are several factors to consider that can make or break your business. From quality and reliability to customer service and after-sales support, here’s what you should look for:

Quality of Construction and Materials UsedA top-tier sandwich machine manufacturer will prioritize the use of high-quality materials and robust construction. This ensures that the machines are not only durable but also capable of withstanding the demands of a busy kitchen environment. Look for manufacturers that use stainless steel components, as they are known for their corrosion resistance and longevity.

Versatility in Machine CapabilitiesDifferent businesses have different needs when it comes to sandwich preparation. A good manufacturer offers a range of machines that cater to various sandwich styles, from simple ham and cheese to gourmet options with multiple fillings and toppings. Consider whether the manufacturer’s offerings align with the variety of sandwiches you plan to serve.

User-Friendly DesignNo matter how advanced a sandwich machine is, it won’t be of much use if it’s not easy to operate. Look for manufacturers that focus on intuitive design and user-friendly interfaces. Machines with programmable settings and easy-to-clean parts can significantly reduce training time for staff and maintenance efforts.

Customization OptionsEvery business has its unique requirements. A reputable manufacturer will offer customization services, allowing you to tailor the machine to your specific needs. This could include adjustments to the size of the sandwiches, the placement of fillings, or even integrating additional features that enhance the production process.

Service and SupportThe best sandwich machines are only as good as the support they receive. A manufacturer that offers comprehensive after-sales service is crucial. This includes installation assistance, regular maintenance, and quick response to any technical issues. A strong warranty and service contract can provide peace of mind and reduce downtime.

Technology IntegrationModern sandwich machines often come equipped with advanced technology that can streamline operations. Look for manufacturers that integrate features like automatic cutting, portion control, and even the ability to connect with kitchen management systems. These technologies can lead to more consistent and efficient production.

Reputation and Industry RecognitionThe reputation of a sandwich machine manufacturer speaks volumes about the quality of their products. Check for awards, certifications, and testimonials from other businesses in your industry. A manufacturer with a strong track record of delivering reliable and innovative machines is more likely to meet your expectations.

Cost-EffectivenessWhile investing in a high-quality sandwich machine is essential, it’s also important to consider the overall cost-effectiveness. This includes not only the initial purchase price but also the long-term savings on maintenance, energy consumption, and potential for increased productivity. A good manufacturer will provide a balanced solution that meets your needs without breaking the bank.

Local Support and DistributionBeing able to access support and replacement parts quickly is crucial. Opt for a manufacturer with a strong presence in your region or country. This ensures that you can receive prompt service and reduce the risk of prolonged downtime.

Training and DocumentationA thorough training program and comprehensive documentation can be the difference between a smooth transition and a headache. A manufacturer that provides comprehensive training and detailed manuals will help ensure that your staff can operate the machine efficiently and safely.

Remember, the right sandwich machine manufacturer for your needs is one that understands your business goals, offers a product that aligns with your operational requirements, and provides the support needed to keep your business running smoothly. Take the time to research and compare different manufacturers to find the perfect match for your sandwich-making operations.

In the world of fast-paced food service, automatic sandwich machines have emerged as a game-changer, streamlining the process of creating mouthwatering sandwiches with ease. Here’s a look at some success stories that showcase the transformative power of these innovative machines.

The first story involves a bustling café that, despite offering a variety of fresh sandwiches, found themselves overwhelmed with long queues during peak hours. The manual sandwich preparation was time-consuming, and customers were left waiting for their orders. After investing in an automatic sandwich machine, the café experienced a significant reduction in wait times. The machine’s ability to assemble sandwiches quickly and consistently meant that even complex creations could be made swiftly, allowing staff to focus on customer service and creating a more enjoyable experience for patrons.

In another instance, a food truck business discovered that their sandwiches, while popular, were not being made to their usual high standards due to the inconsistent conditions of their mobile kitchen. They decided to invest in an automatic sandwich machine that could ensure consistent quality regardless of the environment. The results were impressive: their sandwiches now looked and tasted uniform, which not only pleased the customers but also helped the business build a reputation for reliability and quality on the go.

A fast-food chain faced a unique challenge when they opened a location in a small town with a diverse population. They needed a sandwich solution that could cater to various dietary preferences, including vegetarian, vegan, and gluten-free options. By selecting an automatic sandwich machine that allowed for modular components and customizable settings, they were able to quickly and efficiently accommodate different needs. The machine’s versatility became a selling point, as it allowed them to offer a wide array of sandwiches without the need for extensive training or preparation.

A sports stadium operator found that their food vendors were struggling to keep up with the high demand during games. The stadium was known for its variety of food offerings, but the sandwiches were a hit that needed a boost. They introduced an automatic sandwich machine that could churn out sandwiches at a high rate without compromising on quality. The result was a satisfied crowd, with many patrons noting the speed and cleanliness of the service as standout features of their visit.

In a university cafeteria, the sandwich line was a popular spot for students, but it was also the slowest. With limited time for breaks between classes, students didn’t have patience for long waits. An automatic sandwich machine was introduced, allowing for a variety of fillings to be pre-programmed into the machine, which could then combine them with fresh bread in a flash. The new system cut down the waiting time significantly, improving the overall satisfaction of the students who could now grab their sandwiches and head off to class without delay.

A health-conscious food market operator wanted to offer their customers a range of sandwiches that were both nutritious and delicious. They chose an automatic sandwich machine that not only made the process quick but also featured options for low-carb and high-protein fillings. The machine’s ability to heat and toast bread to the perfect crispness, while also cooking fillings to the right temperature, allowed the market to offer a selection of sandwiches that appealed to a broad demographic, from students to fitness enthusiasts.

Each of these success stories demonstrates how automatic sandwich machines have the power to elevate the food service experience. From reducing wait times to accommodating diverse dietary needs and maintaining high-quality standards, these machines are not just tools; they are the cornerstone of efficient and satisfying sandwich preparation in a variety of settings. The testament to their effectiveness is the positive impact they’ve had on businesses, improving customer satisfaction and operational efficiency alike.

In the evolving world of food service, the future of sandwich making is set to be shaped by innovative technologies and advanced manufacturing processes. Here’s a glimpse into what sandwich machine manufacturers are poised to offer in the coming years.

Precision Engineering: As technology advances, sandwich machines are becoming more precise in their operation, ensuring consistent and uniform results every time. The future holds promise for machines that can tailor the texture, size, and shape of sandwiches to meet specific preferences.

Smart Integration: Manufacturers are increasingly focusing on integrating smart technology into sandwich machines. This could include features like real-time monitoring, predictive maintenance, and remote diagnostics, making it easier for operators to manage their machines efficiently.

Customization at Scale: The ability to customize sandwiches at scale is a game-changer for the industry. Future sandwich machines may be equipped with modular components that allow for easy swapping of parts to accommodate various fillings, bread types, and toppings, ensuring a diverse menu without the need for multiple machines.

Sustainability Efforts: With growing environmental concerns, sandwich machine manufacturers are looking to reduce the carbon footprint of their products. This could mean the development of energy-efficient machines, eco-friendly materials, and even recyclable or biodegradable components.

Health and Safety Features: As health codes and customer expectations evolve, sandwich machines are likely to incorporate more advanced health and safety features. This could include automated cleaning cycles, integrated temperature controls, and even allergen detection systems to ensure food safety.

Mobile and Flexible Solutions: The future of sandwich making may see an increase in mobile and flexible sandwich machines. These could be designed for use in food trucks, pop-up restaurants, or events, offering a convenient and adaptable solution for operators.

Integration with Other Food Service Equipment: Manufacturers are exploring ways to integrate sandwich machines with other food service equipment, creating seamless workflows. For example, a sandwich machine could be connected to an automated bread warmer or a cold storage system to maintain the freshness of ingredients.

User Experience: The user interface of sandwich machines is likely to become more intuitive and user-friendly. Touchscreen controls, voice command capabilities, and even augmented reality (AR) guides for maintenance and operation are potential advancements.

Data-Driven Insights: With the rise of the Internet of Things (IoT), sandwich machines of the future could be equipped with sensors that collect data on usage patterns, maintenance schedules, and energy consumption. This data could be analyzed to optimize performance and reduce downtime.

Collaborative Development: The next generation of sandwich machines may emerge from a collaborative effort between manufacturers, chefs, and foodservice operators. This could lead to machines that not only produce great sandwiches but also offer unique features that cater to specific industry needs.

Emphasis on Speed and Scalability: As the demand for quick service continues to grow, sandwich machines will likely focus on speed and scalability. Future models could handle higher volumes with quicker throughput, making them ideal for busy restaurants and cafes.

Continuous Innovation: The future of sandwich making is not limited to a single feature or technology. It’s a continuous cycle of innovation, where each new advancement builds upon the last, leading to more efficient, versatile, and satisfying sandwich experiences for customers worldwide.

Global Trends Influence: Sandwich machine manufacturers will continue to be influenced by global food trends. This means we might see machines capable of producing international sandwich variations, from traditional Italian paninis to Japanese-style gyozas.

Enhanced Aesthetics: The design of sandwich machines is also expected to evolve, with a focus on aesthetics that complement modern kitchen environments. Sleek, modern designs could become standard, enhancing the overall look and feel of foodservice establishments.

Economic Viability: As technology advances, manufacturers will strive to ensure that the benefits of new sandwich machines are economically viable for businesses of all sizes. This could involve offering flexible financing options or scalable solutions that grow with the business.

The future of sandwich making is bright, and with manufacturers pushing the boundaries of what’s possible, we can expect to see a wide array of innovations that will revolutionize the way we think about and enjoy sandwiches.