Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In an era where technology continues to redefine the way we live and work, the food industry is no exception. One of the most intriguing transformations taking place is the rise of automated sandwich production lines, a phenomenon that’s reshaping how we think about fast food.

The fast food industry has seen a remarkable transformation over the years, with automation playing a pivotal role in this evolution. From the early days of mechanical fryers to today’s sophisticated robotic kitchens, the integration of technology has been a gradual yet significant shift.

As consumer demand for speed and convenience grew, so did the need for more efficient food production methods. Fast food chains found themselves under pressure to keep up with the pace, and this led to the exploration of automation as a solution.

The introduction of automated systems in fast food restaurants has been a response to the need for consistency and scalability. These systems can handle high volumes of orders with minimal human intervention, ensuring that every customer receives their meal with the same level of quality and speed.

The rise of automation in the fast food industry has also been driven by the increasing complexity of menu offerings. Chains now offer a wide variety of items, from classic burgers to exotic wraps, and automated lines can be programmed to produce each item with precision.

With the advent of robotics and AI, the capabilities of automated systems have expanded. They can now perform tasks that were once exclusively done by humans, such as slicing, seasoning, and packaging, all while maintaining a high level of accuracy and cleanliness.

The impact of automation on the fast food industry is not just about increasing output; it’s also about improving the overall customer experience. By reducing wait times and ensuring consistent service, automated systems help to create a more satisfying dining experience for patrons.

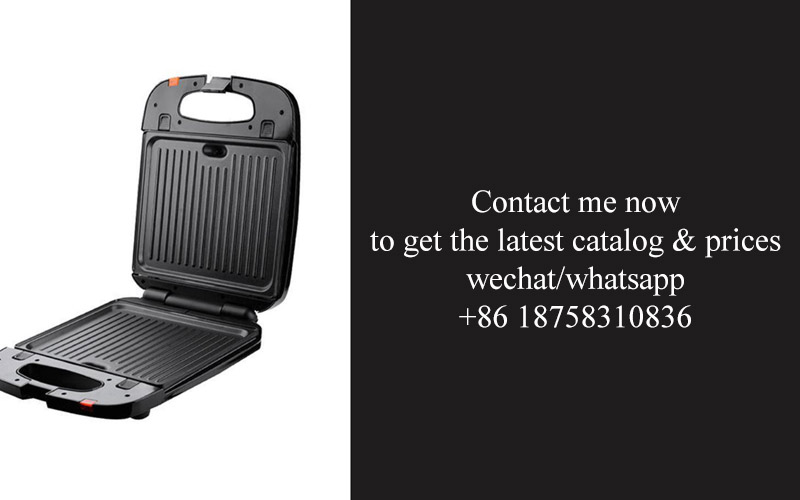

These days, the heart of many fast food kitchens is no longer a bustling team of chefs. Instead, it’s the automated sandwich production line, a marvel of modern technology that whips up sandwiches with precision and speed.

Imagine rows of machines, each with its specific task—slicing bread, spreading condiments, and adding fillings. It’s like a well-oiled machine, each part working in harmony to create a perfectly assembled sandwich.

The production line is designed to handle a variety of sandwiches, from classic burgers to gourmet options. It can switch between different recipes with a simple software update, making it versatile and adaptable to changing trends.

The process is straightforward yet efficient. The bread is fed into the line, where it’s precisely sliced and heated. Next, it’s topped with a selection of meats, cheeses, and vegetables, all measured and placed with incredible accuracy. A quick spread of mayonnaise or mustard, and the sandwich is ready for the next step.

What’s most impressive about these lines is their consistency. Every sandwich comes out looking and tasting the same, thanks to the automation of every aspect of the production process. It’s a far cry from the days when a sandwich could vary greatly from one person’s hands to another’s.

And let’s not forget about the cleanliness. These automated lines are designed to minimize human contact, reducing the risk of contamination and ensuring that every sandwich is safe to eat. It’s a testament to how far food safety has come in the fast food industry.

The automated sandwich production line operates with a series of interconnected steps that ensure a seamless and efficient process.

Bread is the starting point, as it’s fed into the line where it’s sliced to the desired thickness. This ensures uniformity across all sandwiches.

Next, the sliced bread moves to a condiment station. Here, a precise amount of spreads like mayonnaise, mustard, or cheese is applied to the bread, all controlled by automated dispensers.

As the bread moves along, it encounters a filling station. Various meats, cheeses, and vegetables are added, with robotic arms carefully placing each ingredient according to the recipe.

After the fillings are added, the sandwich is passed through a heating unit. This not only warms the sandwich but also ensures the condiments meld with the bread and fillings.

Once heated, the sandwich is then sealed in a wrapping machine. It’s carefully wrapped to maintain freshness and to make it easy for the customer to handle.

Finally, the wrapped sandwich is conveyed to a packing area, where it’s grouped into batches and ready for distribution. The entire process is monitored and controlled by an advanced software system that can adjust settings and recipes on the fly.

Automation in sandwich production brings a host of advantages that can significantly boost a business’s bottom line.

One of the most noticeable benefits is the increase in speed. The line can churn out sandwiches at a rapid pace, reducing wait times for customers and keeping the line moving smoothly.

Consistency is key in the food industry, and an automated line delivers it in spades. Every sandwich is made to the same specifications, ensuring that customers receive a product that meets or exceeds their expectations.

Maintaining high standards of food safety is crucial, and these lines do it effortlessly. With minimal human contact and precise handling, the risk of contamination is greatly reduced.

The efficiency of an automated sandwich production line also means lower labor costs. While there’s still a need for operators to manage and maintain the equipment, the reduced need for a large kitchen staff can lead to significant savings.

Another advantage is the scalability of these lines. They can easily handle increased demand during peak times without sacrificing quality or speed, making them a valuable asset for businesses looking to grow.

Lastly, the technology behind these lines is often designed with sustainability in mind. From energy-efficient motors to waste-reducing processes, these systems can help businesses operate more responsibly.

Businesses are constantly seeking ways to improve efficiency, and the automated sandwich production line is a game-changer in this regard. The line’s ability to produce sandwiches at a rapid rate is a major time-saver.

This speed translates to faster service for customers, which is a big draw in the fast-food industry. Happy customers are more likely to return and recommend the business to others.

The efficiency of the line doesn’t just stop at production speed. It also minimizes down time, as maintenance and cleaning are streamlined processes that keep the line running smoothly.

By automating sandwich assembly, businesses can handle higher volumes of orders without the stress of manual labor, allowing them to cater to larger crowds during peak times.

The quick throughput also means that the kitchen can process more orders overall, which can lead to increased sales and revenue for the business.

In the competitive fast-food landscape, the ability to serve a large number of customers in a short time frame can be a significant advantage, setting businesses apart from their slower-paced competitors.

The beauty of an automated sandwich production line lies in its ability to deliver consistent quality with every sandwich.

From the slicing of bread to the application of condiments, each step is controlled with precision, ensuring that every ingredient is added in the perfect amount.

This level of control is crucial for maintaining brand standards. Whether it’s a classic cheeseburger or a gourmet option, the outcome is the same—high-quality sandwiches that reflect the brand’s image.

Consistency also means that customers know what to expect each time they visit. This predictability can build trust and loyalty, as they feel confident in the product they’re purchasing.

The elimination of human error in the production process is a key factor in achieving this consistency. Automated lines are programmed to perform tasks with the same accuracy every time, resulting in a consistent product.

Moreover, the quality control aspect doesn’t end at the production line. These systems can also track and record each sandwich’s production details, making it easier to trace any issues that may arise.

In the fast-paced world of food service, the assurance of a consistently high-quality product can be a major differentiator for businesses looking to stand out in a crowded market.

The future of sandwich making is all about innovation, and the landscape is evolving rapidly.

We’re seeing the integration of AI and machine learning, which allows for predictive analytics and the ability to adapt to changing consumer preferences with remarkable speed.

Advanced robotics are taking sandwich production to new heights, with machines capable of learning and improving over time. This means a continuous evolution in the way we think about food assembly.

The customization of sandwiches is becoming more sophisticated, with automated systems that can cater to a variety of dietary preferences and restrictions, offering a personal touch to every meal.

Sustainability is also shaping the future of sandwich making. New technologies are focusing on reducing waste and energy consumption, ensuring that the process is environmentally friendly.

Moreover, the concept of on-demand food production is gaining traction. Imagine ordering a sandwich online and having it freshly made and delivered to your doorstep in a matter of minutes.

The future isn’t just about technology; it’s also about enhancing the overall dining experience. Interactive interfaces and digital enhancements could transform the way we interact with our food, making it more engaging and fun.

As innovation continues to push the boundaries of sandwich making, we can expect to see even more creative and efficient ways to enjoy our favorite meals.

Automated sandwich production lines are designed with environmental considerations in mind, making them a greener choice for food production.

These lines often use energy-efficient motors and lighting, which significantly reduce the carbon footprint compared to traditional methods.

By minimizing waste and optimizing ingredient usage, these systems help to cut down on the amount of food that goes to landfill, contributing to a more sustainable approach.

The automated nature of the production process also means less water usage, as there’s no need for hand-washing or manual cleaning that can be water-intensive.

Recycling and reusing materials are made easier with automated systems, as they often come equipped with recycling bins for packaging and other materials.

The reduction in manual labor means fewer vehicles on the road for employee transportation, further reducing the environmental impact.

In addition to energy and resource savings, these lines also produce less noise pollution, creating a more pleasant working environment and minimizing the disturbance to nearby communities.

Lastly, the long-term sustainability of these systems is a key factor. They are built to last, reducing the need for frequent replacements and the waste associated with them.

While automation brings efficiency and consistency, it’s important to remember the value of the human touch.

Customer service remains a cornerstone of the dining experience, and that’s where employees play a crucial role. They can offer a personal touch that machines simply can’t replicate.

Employees can engage with customers, providing recommendations, answering questions, and ensuring that each patron feels valued.

The presence of human staff can also create a sense of community and familiarity within a restaurant, something that can be lost with a fully automated service.

Training employees to work alongside automated systems can enhance their skills and make them more versatile, which is beneficial for both the business and the customers.

By combining the speed and accuracy of automation with the personal interaction of human staff, businesses can offer a more balanced and satisfying experience.

It’s about finding that sweet spot where technology and humanity coexist, ensuring that customers feel taken care of without sacrificing the efficiency of automated processes.

Embracing the automated sandwich revolution means embracing a future where efficiency meets convenience.

These production lines are not just about speeding up service; they’re about ensuring that every sandwich is crafted to perfection, every time.

The blend of automation and human expertise creates a dynamic that’s hard to beat, offering a balance between speed and quality.

As the industry continues to evolve, businesses that adopt these systems are positioning themselves at the forefront of innovation.

By integrating technology with the human element, we’re not just revolutionizing how sandwiches are made—we’re reshaping the entire food service experience.