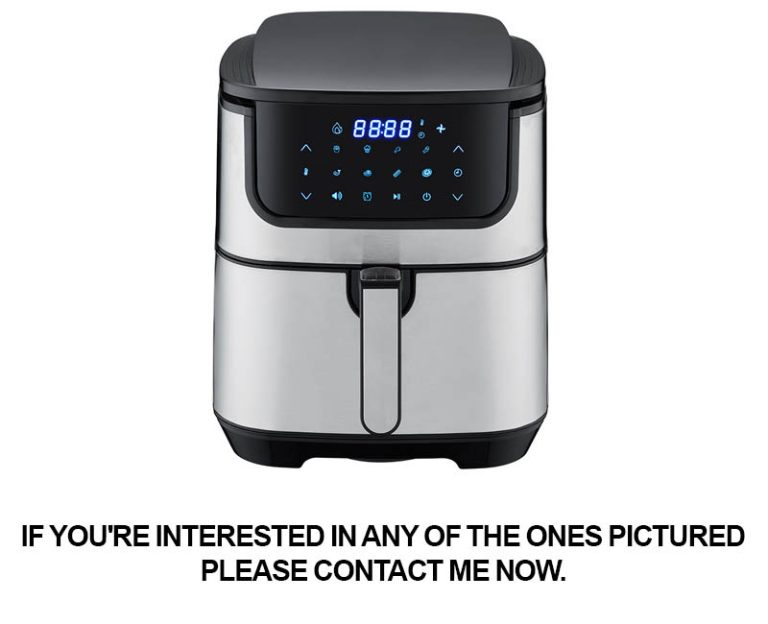

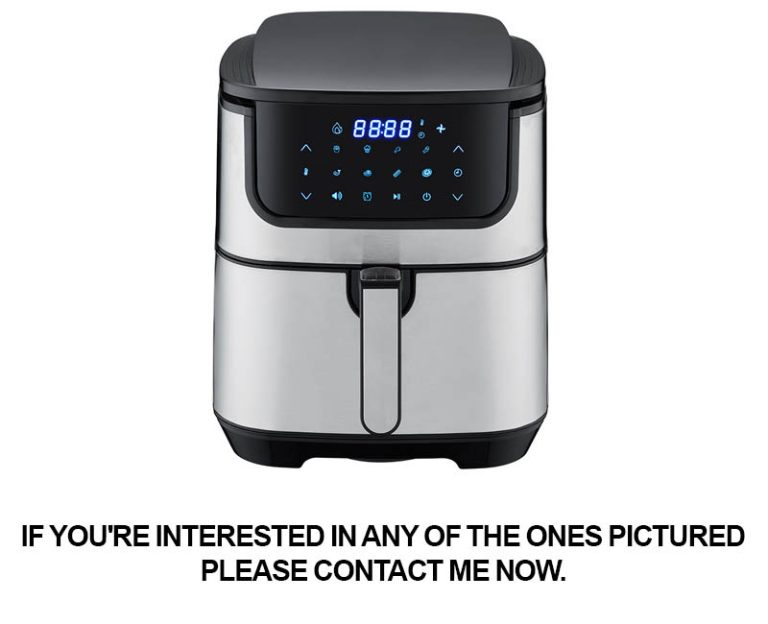

The CE-certified air fryer OEM market has seen a surge due to the popularity of health-aware cooking. OEM producers are focusing on modern designs, along with modular devices, smart manage systems, and

materials, to meet diverse consumer wishes. trends like environmental sustainability, emblem differentiation, and e-trade are shaping the industry, with OEMs participating across industries and increasing across the world. data-pushed insights are essential for know-how market needs, optimizing product design, and staying competitive, as OEMs leverage consumer conduct, product lifecycle, and competitor evaluation to tell their techniques.

Amidst the backdrop of globalization, sandwich maker factories are undergoing substantial transformation to cater to the evolving market. EAC compliant sandwich makers are crucial for european marketplace entry and emblem photograph. those home equipment are integrating clever capabilities, like smart chips for computerized cooking, and multi-purposeful abilities which includes toasting, frying, and grilling. portable designs are popular for on-the-go sandwiches, at the same time as fitness-aware purchasers are trying to find low-fat and

alternatives. by means of focusing on those features, sandwich maker factories can meet diverse desires and preserve a aggressive edge in the dynamic market.

inside the swiftly evolving kitchen equipment industry, low minimum order quantity (MOQ) air fryer producers are capitalizing on market possibilities. driven by the surge in demand for healthful cooking, those producers are gaining a competitive facet thru progressive product designs and forward-thinking market fashion analysis. The low MOQ strategy lets in them to cater to numerous patron needs, lessen in advance investment dangers, and adapt speedy to marketplace modifications. through that specialize in compact, clever features, and

materials, those producers aren’t best assembly purchaser possibilities for healthier, low-fat cooking however additionally improving their emblem image. This method, supported with the aid of enterprise records, is allowing low MOQ air fryer manufacturers to seize considerable market share and foster sustainable increase.

The customizable contact grill OEM is revolutionizing the kitchen appliance marketplace, providing a 30% cost reduction through innovative layout and era. by way of tailoring grills to precise needs, OEMs optimize production, lessen waste, and streamline supply chains, benefiting appliance manufacturers and customers alike. This fashion enhances product competitiveness, fosters customer loyalty, and expands marketplace opportunities, making the touch grill a recreation-changer in the enterprise.

The town’s kitchen appliance enterprise is poised for tremendous growth with the arrival of excessive-extent juicer manufacturing traces, offering high-quality performance and rapid reaction talents. those production lines, capable of assembly marketplace needs rapidly, have obtained accolades for their high capacity and speedy turnaround—making sure a forty eight-hour citation dedication to secure orders. This commitment, along superior generation and shrewd structures, guarantees not handiest velocity but also precision and consumer pleasure. as the enterprise makes a speciality of innovation and nice, these high-quantity juicer production strains are set to revolutionize the market, solidifying city’s role as a leader in appliance efficiency and positive carrier.

The 2200W ecu plug air fryer OEM is gaining traction within the marketplace as a healthy lifestyle cooking fashion continues to upward push. Its reputation is pushed via its low-fats cooking techniques, which align with customer choices for fitness-conscious cooking strategies. The air fryer’s revolutionary layout includes clever temperature manage, multi-practical cooking modes, and

substances, making it a favorite amongst fitness-aware customers. market information shows a regular annual increase charge of 15% in sales, with a massive market share and high consumer satisfaction. because the demand for low-fats, healthy cooking increases, the 2200W eu plug air fryer OEM is poised for persisted boom, profiting from the shift toward wholesome living and sustainable intake.

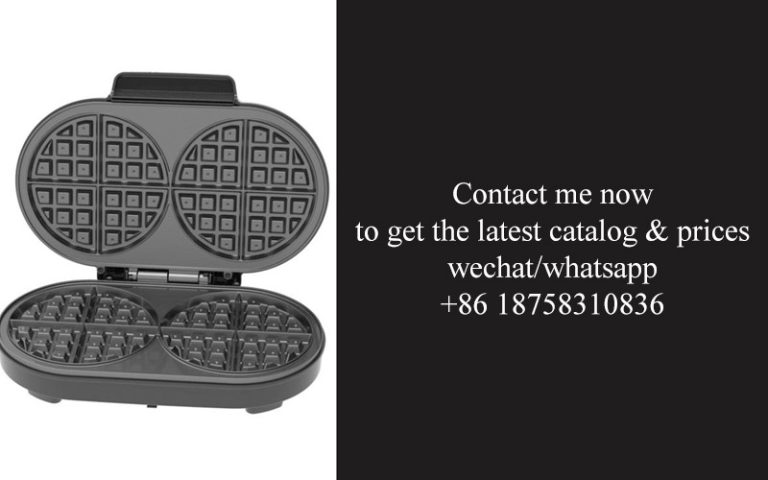

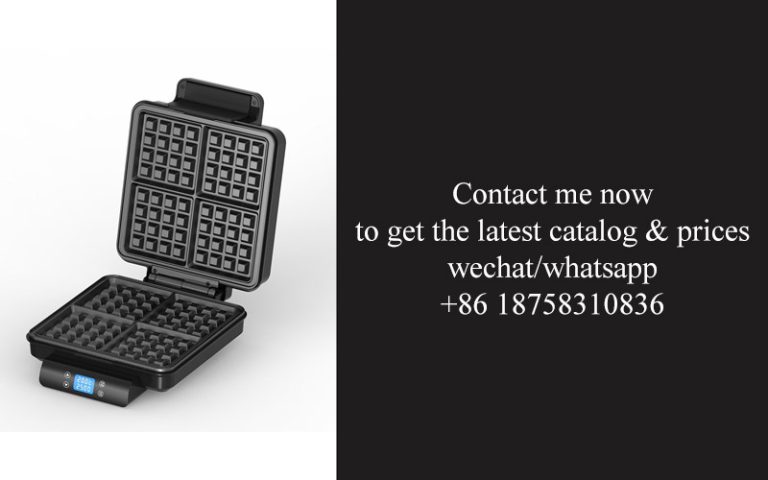

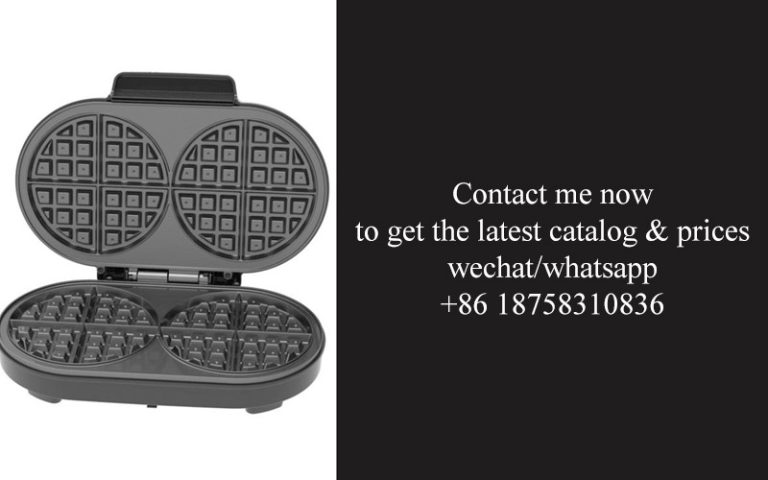

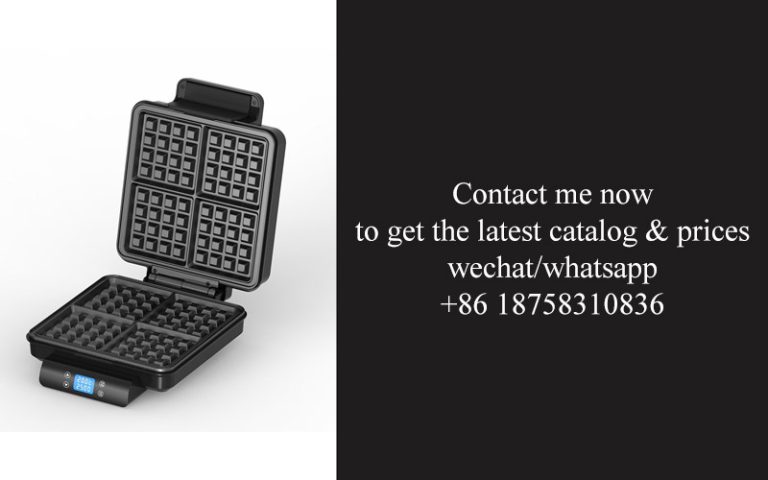

the economic grade waffle maker market is witnessing full-size increase, pushed by means of the demand for quick, green, and various breakfast alternatives. NSF-licensed home equipment are critical, ensuring health and protection requirements are met. innovations like smart control systems,

substances, and multi-purposeful designs are shaping the marketplace, presenting durability and ease of use. As purchaser possibilities evolve, these superior waffle irons, with their consciousness on performance and protection, are poised to dominate the kitchen appliance industry.

The kitchen equipment marketplace is witnessing a shift in the direction of fitness and environmental attention, with a sizeable rise in demand for BPA-free materials in juicers and other kitchen home equipment. This fashion is being pushed with the aid of client recognition of health and environmental issues, main factories to prioritize the usage of non-BPA materials in their manufacturing. those BPA-loose materials no longer only ensure protection and durability however additionally align with the growing fashion of smart technology integration. As generation advances, the industry is poised for endured growth, with modern designs and substances like BPA-unfastened plastics becoming general in equipment production.

The Russian kitchen appliance market is experiencing strong boom, pushed through increasing demand for various and premium products. suppliers need to ensure stable logistics to preserve efficiency and competitiveness. Geographical blessings and mature supply chain management in Russia provide kitchen equipment providers with a strong foundation for short marketplace reaction and cost-powerful operations. green logistics not most effective reduces transportation costs however also complements client pleasure and emblem loyalty. as the enterprise evolves towards smart, strength-efficient, and customized appliances, Russian suppliers leverage their stable logistics to satisfy these evolving demands and comfortable their function in the market.

in the hastily expanding air fryer OEM marketplace, producers are an increasing number of specializing in guarantee alternative services to decorate patron self belief and force sales. as the call for for healthful cooking solutions grows, OEMs are integrating superior capabilities like clever controls and electricity efficiency, at the same time as also offering sturdy warranty rules to differentiate their products. these techniques are critical for manufacturers to stay competitive, as they cater to a health-conscious purchaser base and adapt to the evolving market trends.